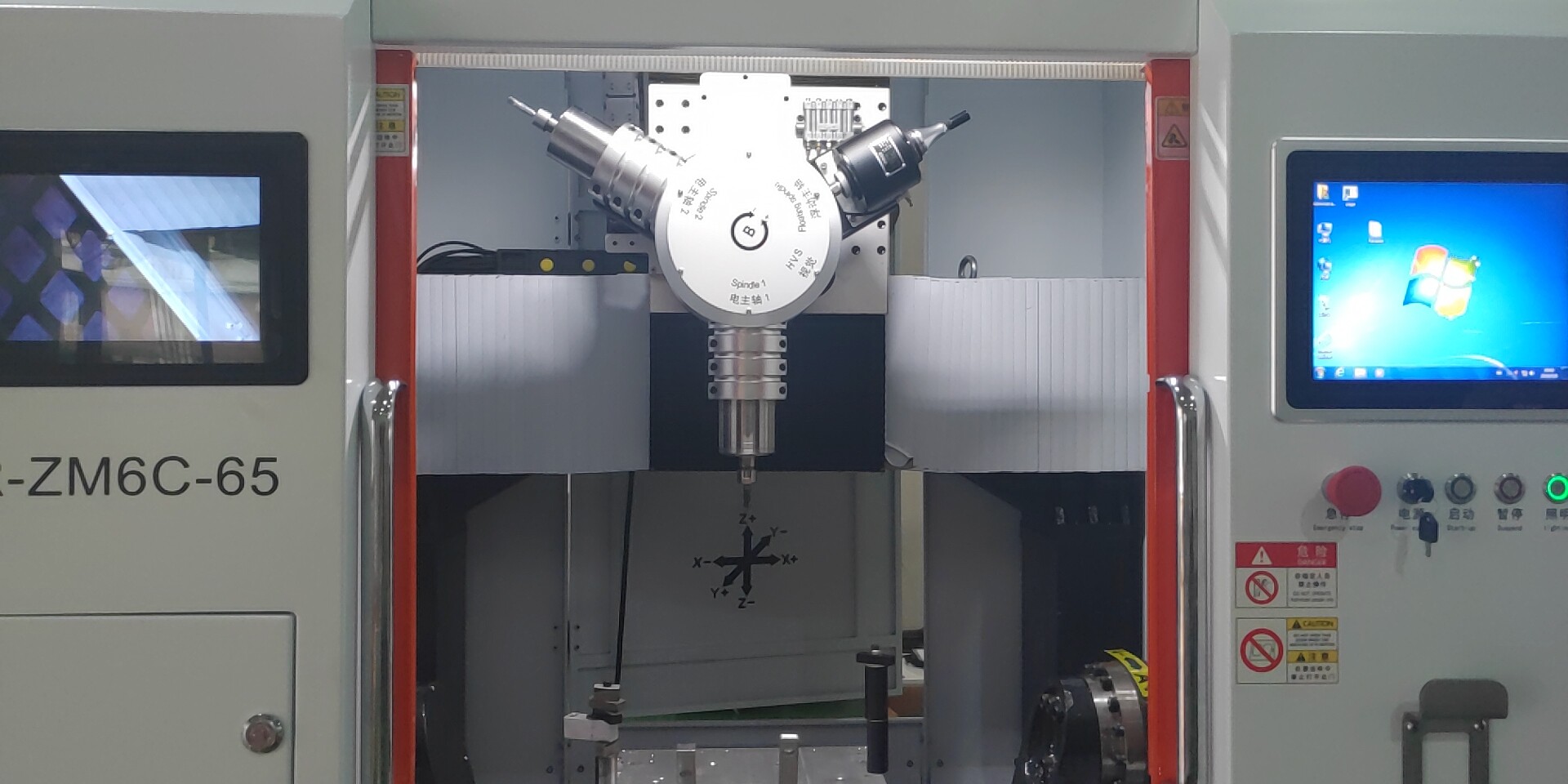

Intelligent automatic die casting deburring machine

Product origin :China

Delivery time :30 Days

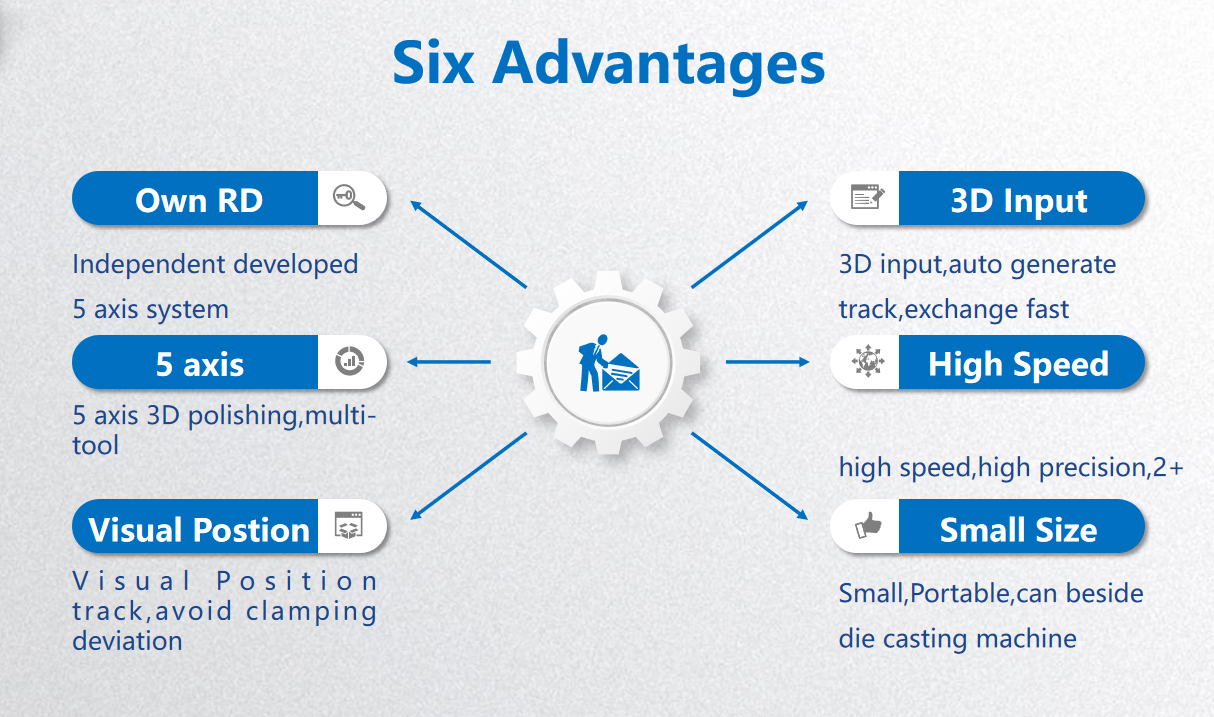

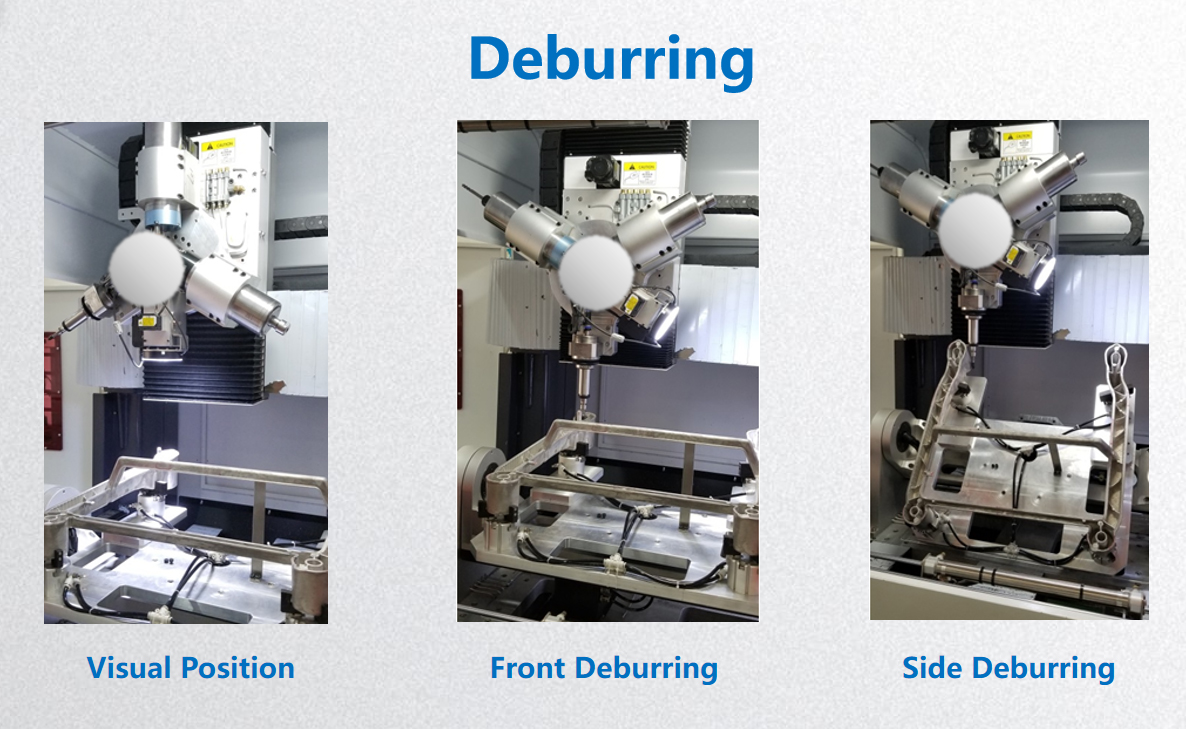

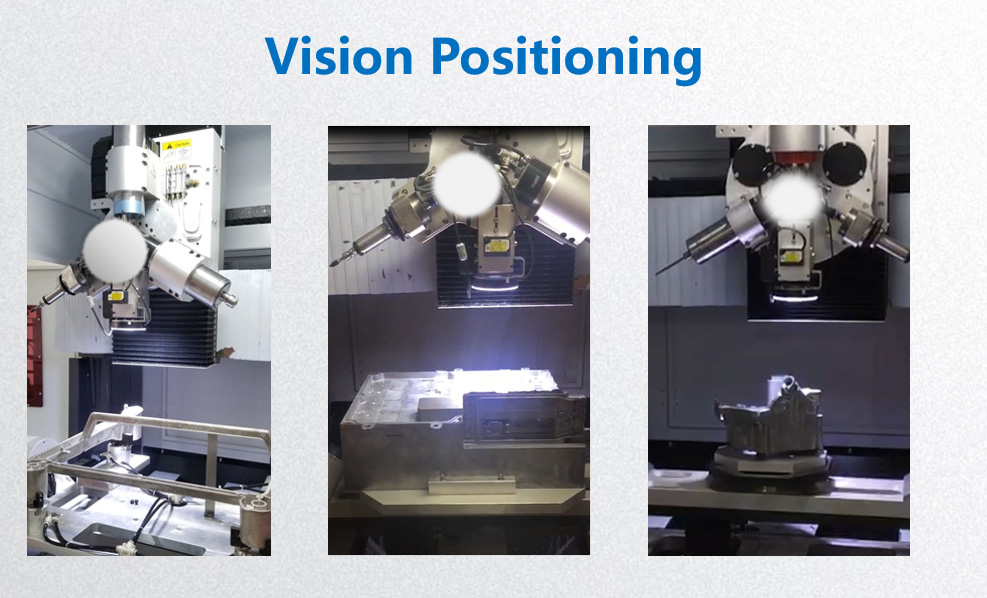

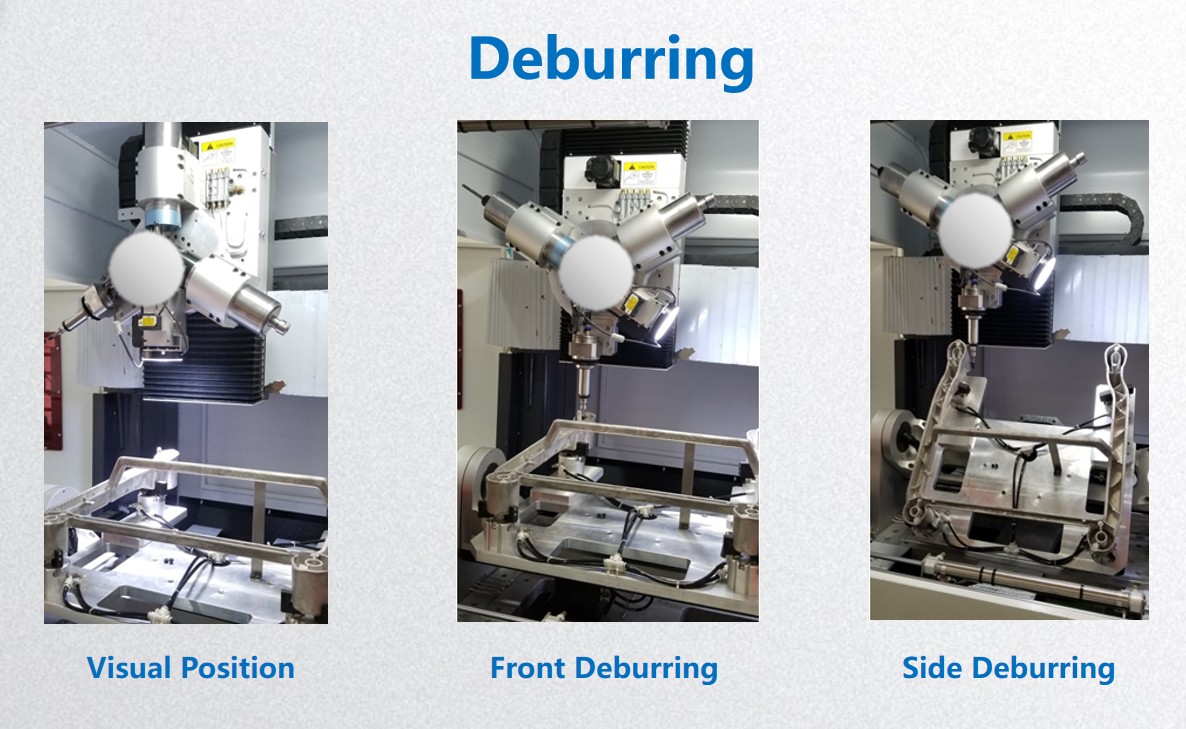

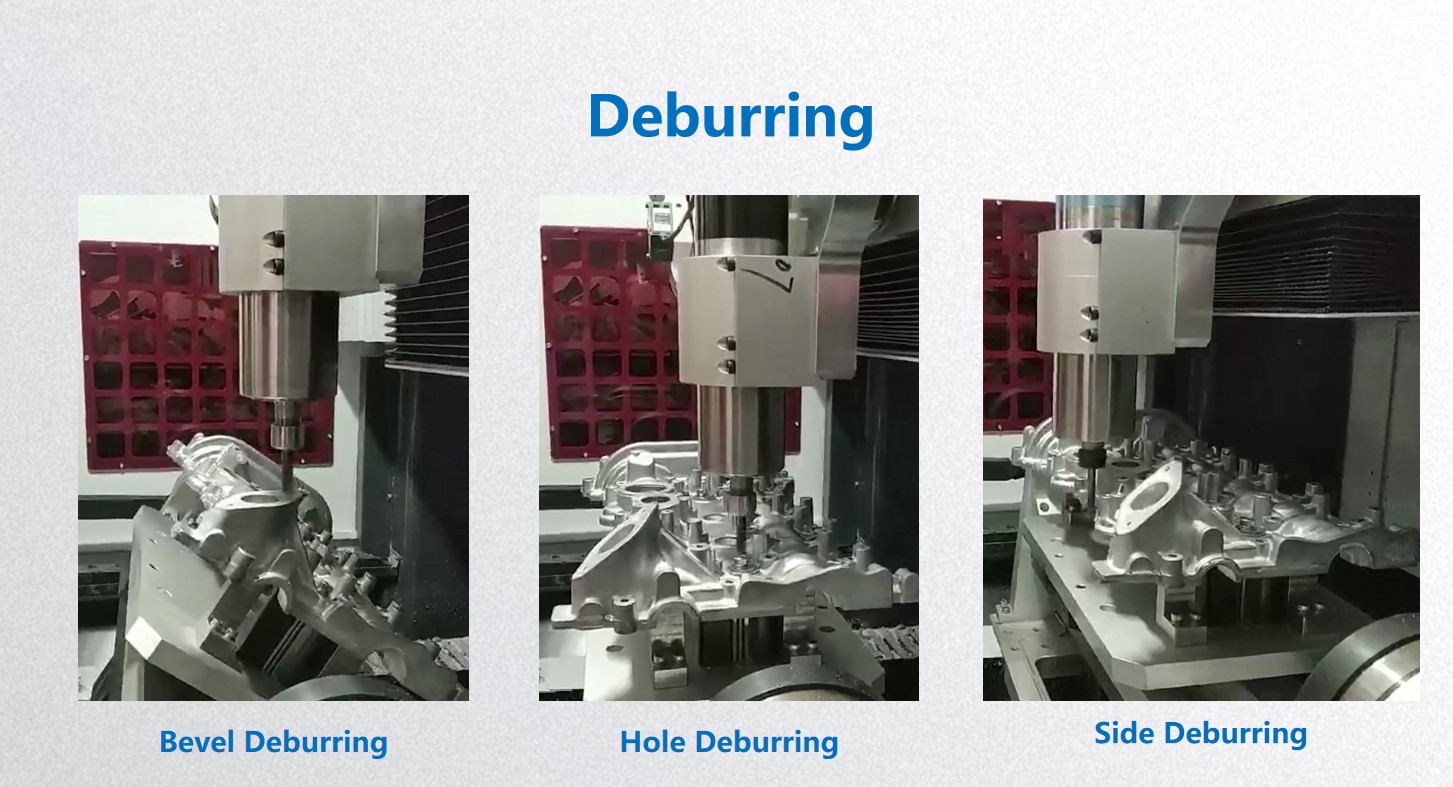

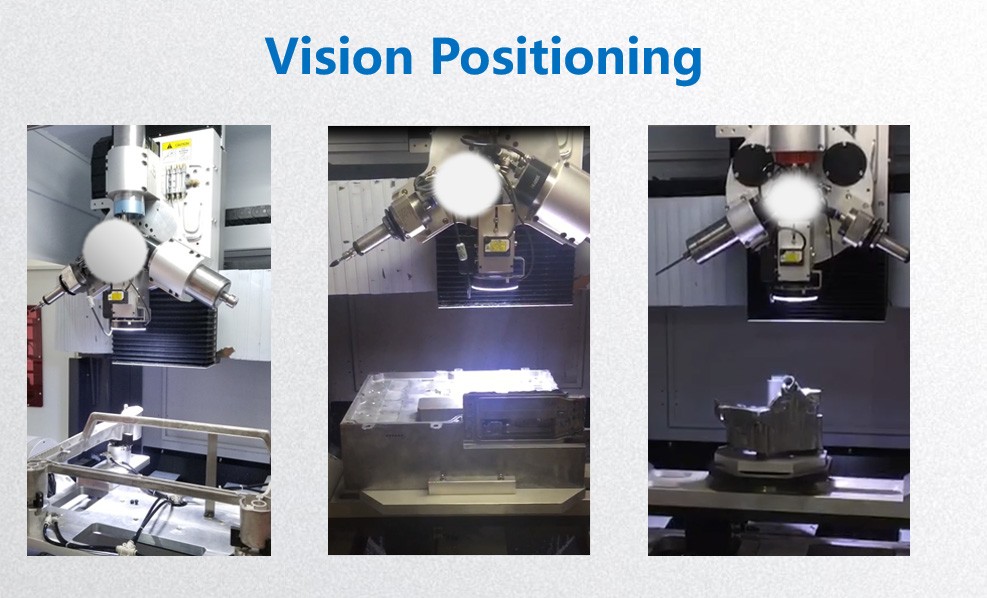

It can be flexibly adjusted and optimized according to the user's workpiece features, and supports the visual positioning and correction function, and the error of the fixture installing. Equipment repeatability <0.01mm. If necessary, the process of part of the 5-axis machining center can be completed.

Intelligent automatic die casting deburring machine can be flexibly adjusted and optimized according to the user's workpiece features, and supports the visual positioning and correction function, and the error of the fixture installing. Equipment repeatability <0.01mm. If necessary, the process of part of the 5-axis machining center can be completed.

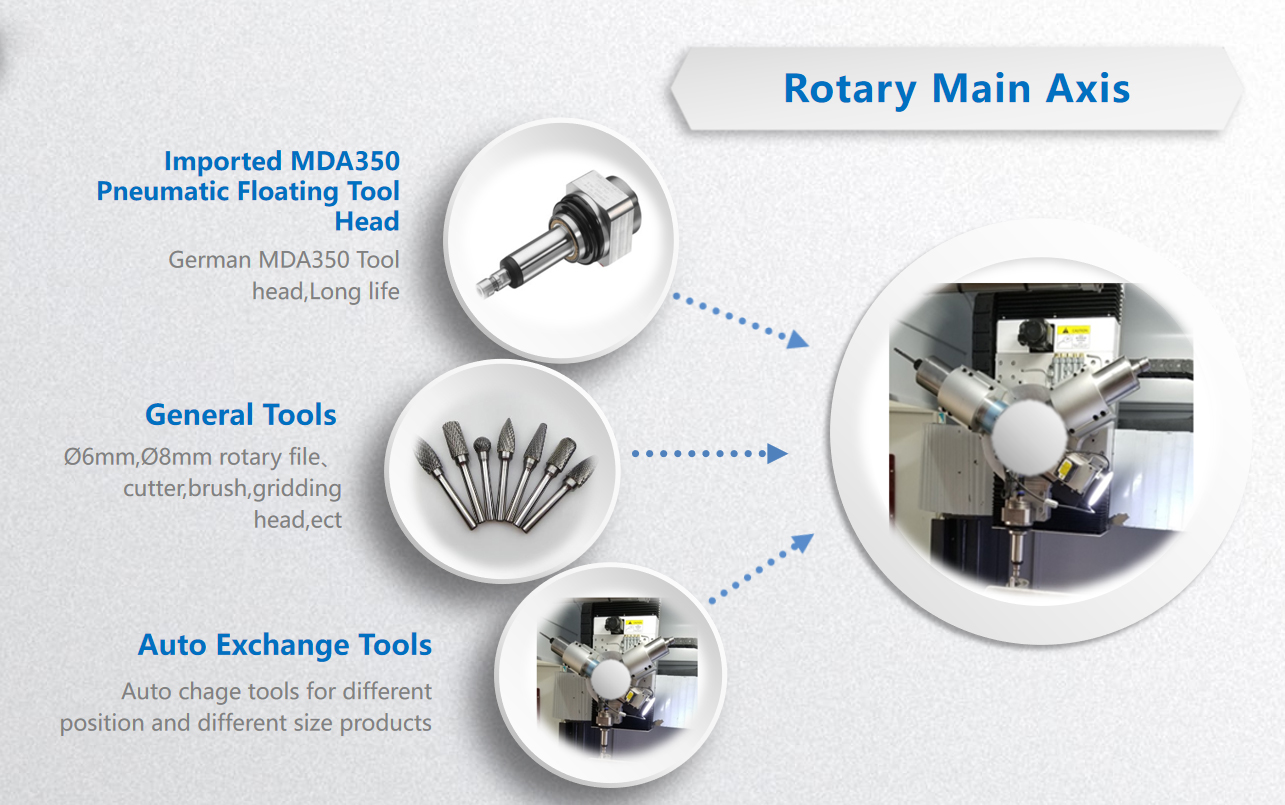

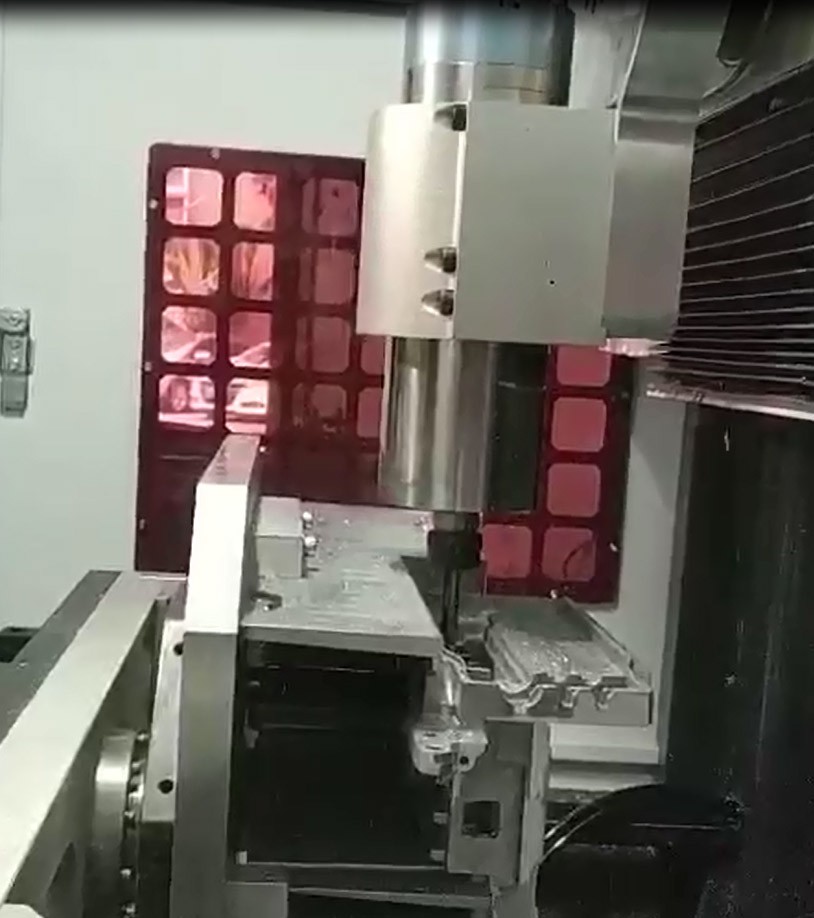

Multi-axis linkage for flat and stereo work while carrying multiple tools. The fixed spindle is combined with the floating spindle to achieve complete polishing and cleaning.

Intelligent automatic die casting deburring machine support 3D import programming, G code program generated by CAM software, the track is more accurate, and manual teaching function, can modify any track at any time, simple operation, more reliable performance.

The speed is fast and the efficiency is high. Due to the combination of multiple tools, the corresponding tool is automatically adjusted for the workpiece structure. Even if the cutting of the runner can achieve high-speed operation, the user's production capacity is greatly improved.

The utility model has the advantages of small volume, convenient movement and strong maneuverability, and can complete the grinding and cleaning work beside the molding machine, thereby reducing the logistics cost and the damage during the transportation.

Intelligent automatic die casting deburring machine is a monolithic structure. The coordinates of the motion axis and the fixture platform are fixed for a long time after being calibrated for the first time. The system has a power-off protection function to ensure that the stored operating procedures are not lost permanently.

The equipment adopts the working principle of cutting mode, which produces less dust, and the particles after cutting can be recycled to enhance the value of scrap. Fully enclosed structure design, high safety factor, smoke detectors, automatic fire extinguishing device and water leakage transition system can be installed according to user requirements.

Model/Specs | LR-ZM6C-65 | LR-ZM6C-40 |

Axis | 6 | 6 |

X stroke Lx01 | 650mm | 400mm |

Y Stroke Ly01 | 550mm | 400mm |

Z Stroke Lz01 | 320mm | 300mm |

A axis rotary angle | 200° | 200° |

B axis rotary angle | 360° | 360° |

C axis rotary angle | 360° | 360° |

Machinable parts envelope circle | Φ720 | Φ600 |

X Repeat accuracy | 0.03mm | 0.02mm |

Y Repeat accuracy | 0.03mm | 0.02mm |

Z Repeat accuracy | 0.03mm | 0.02mm |

A Repeat accuracy | 0.02mm | 0.02mm |

B Repeat accuracy | 0.02mm | 0.02mm |

C Repeat accuracy | 0.02mm | 0.02mm |

X Max. Speed | 530mm/s | 500mm/s |

Y Max. Speed | 530mm/s | 500mm/s |

Z Max. Speed | 530mm/s | 500mm/s |

A Max. Speed | 185°/s | 300°/s |

B Max. Speed | 300°/s | 300°/s |

C Max. Speed | 300°/s | 300°/s |

Max. Integrated Speed | 750mm/s | 700mm/s |

Platform Load Weight | 50kg | 25kg |

Main axis power | 3.5kw | 2.5kw |

Main axis RPM | 5000r~40000r/min | 5000r~40000r/min |

Toll diameter | Φ3~Φ10mm | Φ3~Φ10mm |

Working Voltage | AC320V | AC220V |

Total Driving power | 6.5kw | 4kw |

Machine Size | 1340*1390*2300mm³ | 1200*1200*2000mm³ |

Machine Weight | 2.5t | 2t |

Extension Functions (Optional)

Optional Functions | Brand | Speciality |

Vision System | Japan | For high precision products |

Main Axis | Germany | For hig precision and big cutting surface products |

Automatic fire extinguisher | China | For dusty products |

Filter | China | For dusty products |

Tools Cabinet | China | Store the tools |

Self sucker Polisher | Germany | For flat polishing of the large area products |

File Machine | Germany | For small groove and small gap of the products |

OMRON Control System

High speed multi-axis control

Flexibale height,simple motion control by CAD/CAM

EtherCAT,flexible system structure.

EtherCAT

125s high speed high precision motion control

Support 400V

Safe torque OFF(STO function)

The 5 megapixel industrial camera, combined with a vision controller and motion controller, provides precision measurement and visual correction.