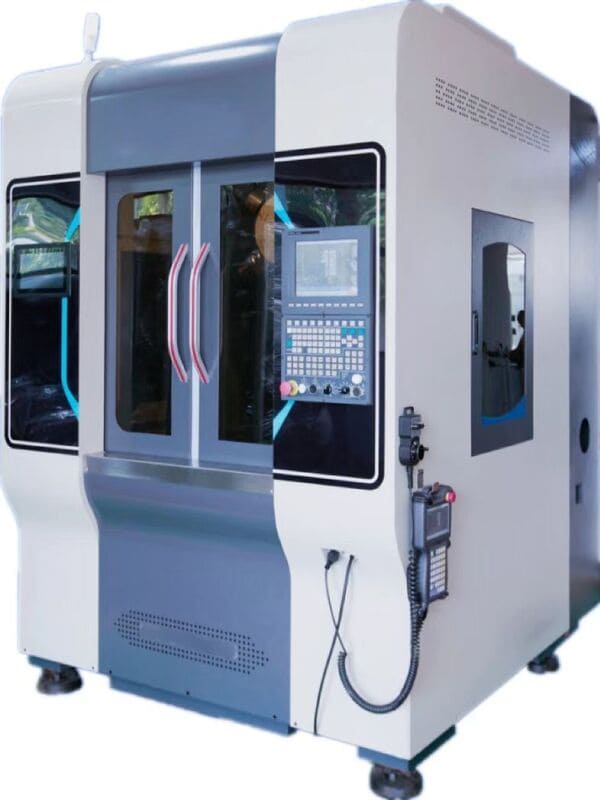

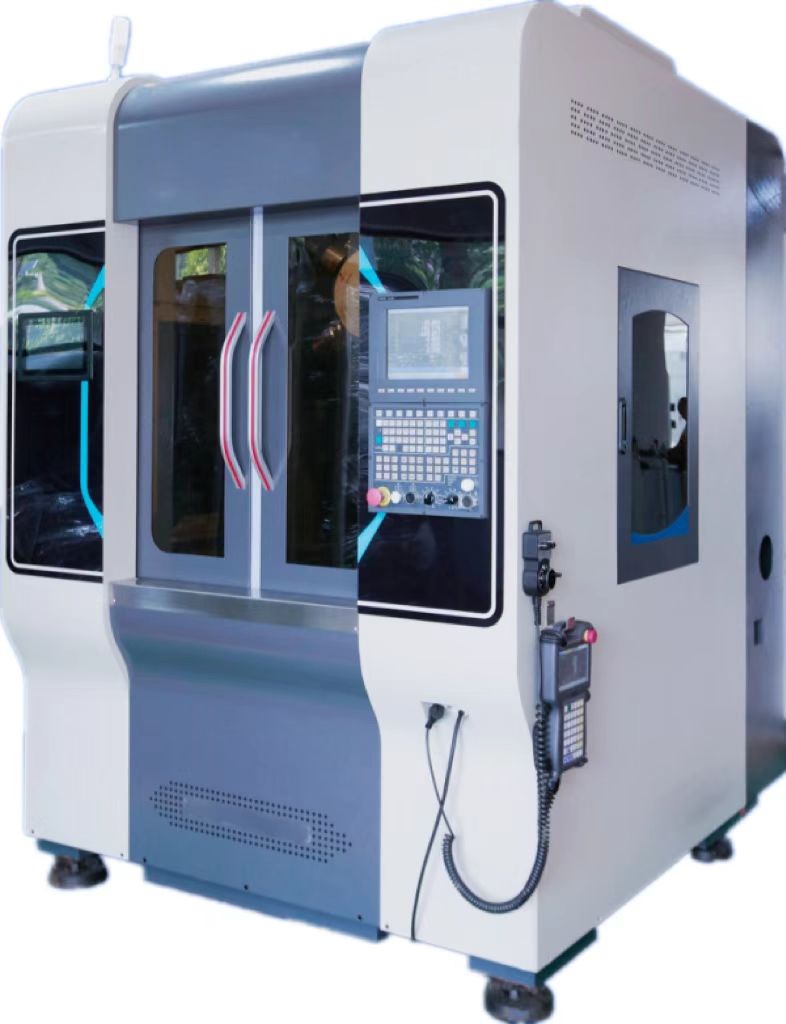

LR-ZM6B Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

We have powerful system configuration, user-friendly and efficient operation, over 8 years of industry experience, advanced technology, self-developed core components, high cost-effectiveness.

Product Overview

LR-ZM6B grinding machine is designed for high-precision and high-efficiency operations. It incorporates the high-speed multi-axis control system and servo motors from Taiwan (SYNTEC), combined with a cast iron structure for rigidity and precision, thus It is an ideal solution for demanding grinding tasks.

Product Features and Advantages

Advanced Control System

LR-ZM6B grinding machine is leveraging by Taiwan SYNTEC's high-speed multi-axis control system with optional RTCP (Real-Time Tool Center Point) functionality, combined with high-performance SYNTEC servo motor.Fast response, smooth operation, and precise position control ensure stable and efficient grinding processes.

Efficient Programming

The SYNTEC system has the capacity to store thousands of programs,allowing one-click retrieval when changing products. This eliminates the need for repetitive programming, significantly improves equipment utilization, and reduces production preparation time.

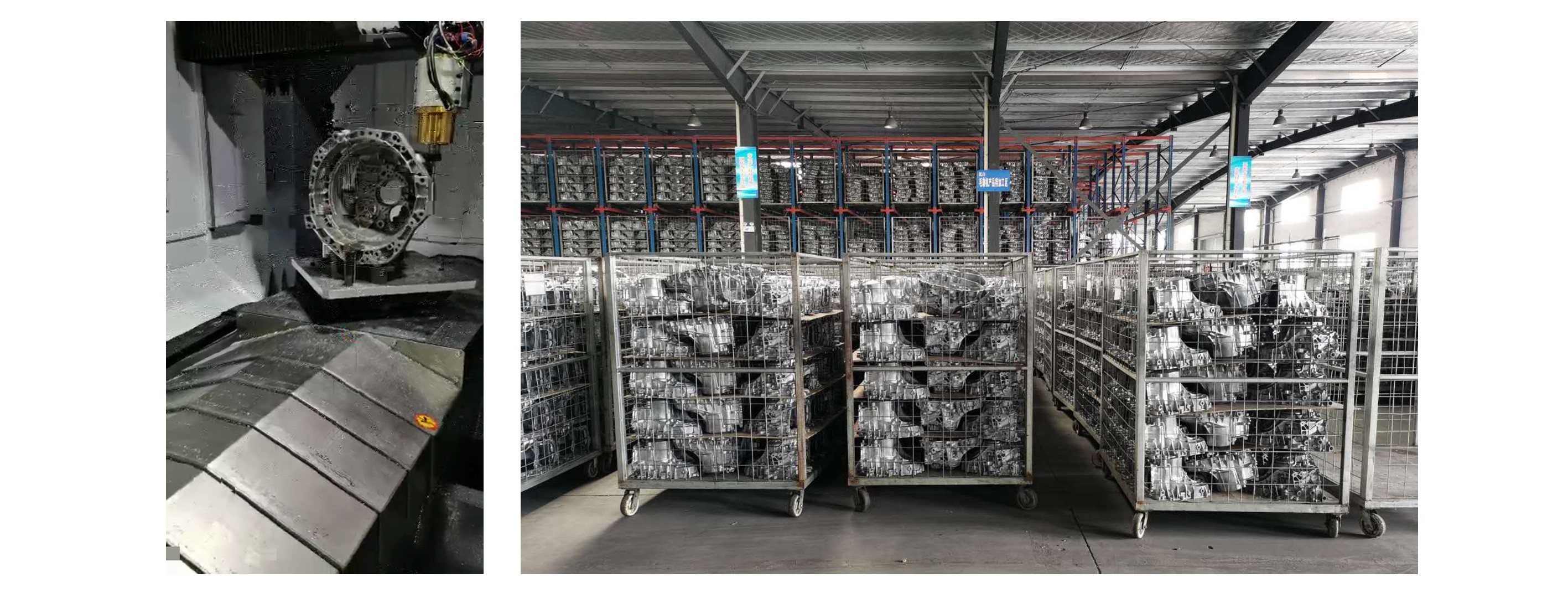

Robust and Stable Construction

LR-ZM6B grinding machine's main structure is crafted from cast iron through a mold opening process. This design confers high rigidity and precision, excellent processing stability, effectively mitigates tool vibration, and allows for a rapid feed rate, making it the perfect choice for grinding and deburring tasks.

Six-axis Linkage for Flexible Machining

Equipped with the ability to move along the X, Y, and Z axis and rotate around the A, B, and C axis, the six-axis linkage of this equipment enables comprehensive multi-directional grinding of workpieces with a single clamping. This results in a broader processing scope and heightened efficiency.

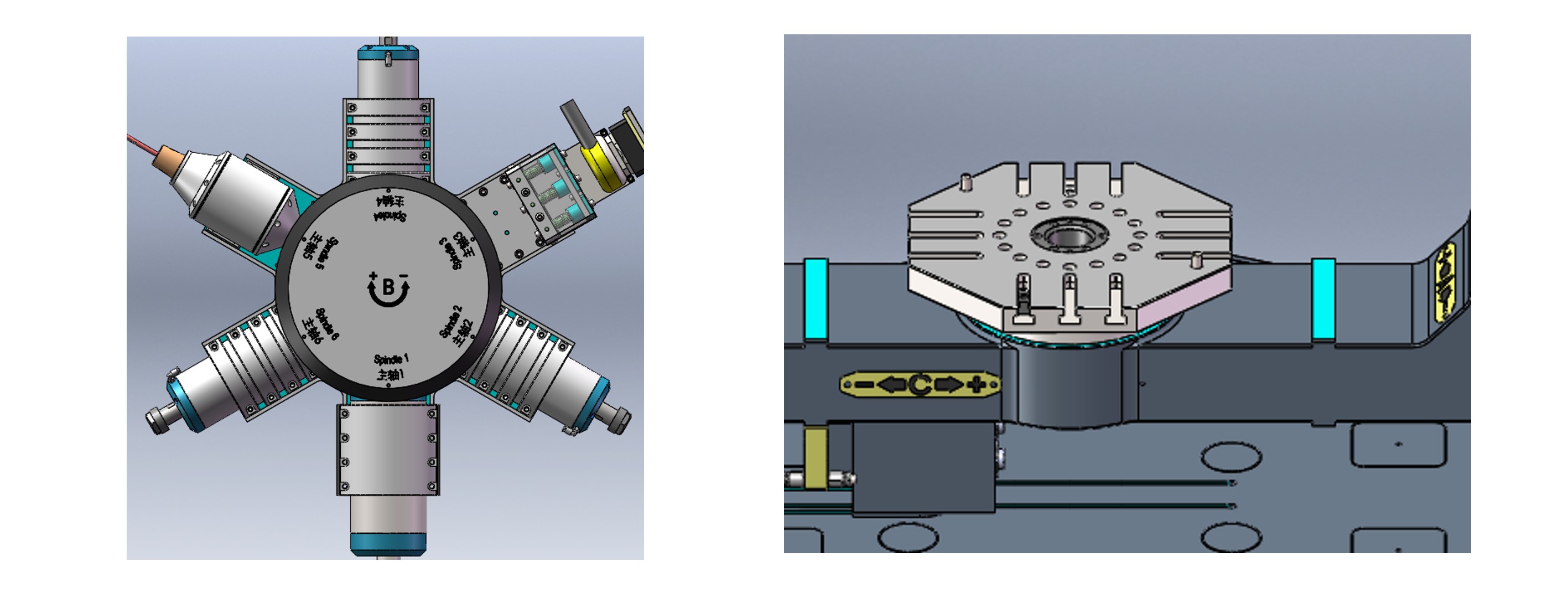

High-Speed Tool Changer for Enhanced Productivity

Fitted with a six-head rotary tool magazine, SYNTEC LR-ZM6B grinding machine enables rapid tool changes without the necessity of a fixed tool changing position This boosts tool changing efficiency and also enables multi-angle inclined machining, catering to the demands of complex workpiece processing.

Flexible Tools for Diverse Applications

The grinding and deburring tools can be adjusted flexibly according to processing requirements, facilitating the optimal combination of flexible and rigid tools. This makes the machine suitable for processing workpieces of various materials and geometries.

Quick Fixture Change For Time and Labor Saving

The worktable is equipped with quick-change locating pins for workholding, enabling rapid installation and switching of fixtures. This reduces the time required for repeated tool alignment and debugging, improving production efficiency.

Automatic Tool Compensation for Cost Reduction

LR-ZM6B grinding machine features an automatic tool compensation function, which effectively extends the service life of grinding tools, reduces tool wear, and lowers production costs.

Compact Design for Easy Movement

LR-ZM6B grinding machine has a compact structure with a small footprint and is easy to move. It can be relocated with a forklift at any time, facilitating workshop layout planning and adapting to various production needs.

Application Scenarios:

Casting machine peripheral operations

Integrated automation operations

Manual loading and unloading operations

Suitable for single operator managing multiple machines

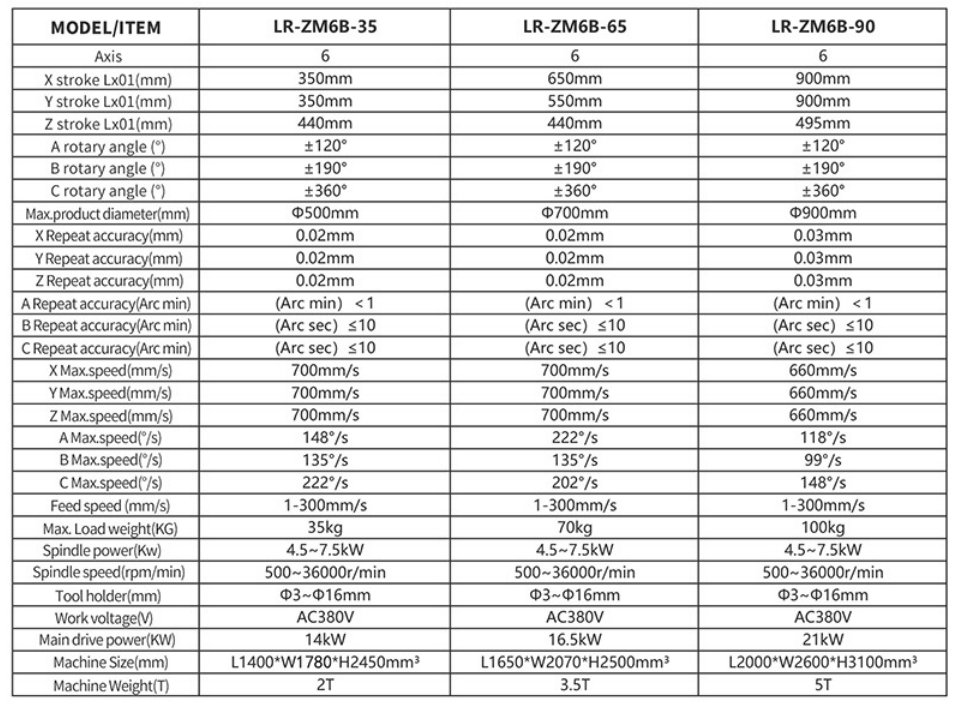

Main Parameters

Why Choose Our Machine?

Higher production efficiency

More precise machining quality

More flexible application scenarios

Lower operating costs

We are committed to providing efficient and reliable grinding and deburring solutions for our customers. Contact us today to learn more about our products!