LR-ZM5C-120 automatic grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The LR-ZM5C-120 is a high-performance five-axis intelligent grinding machine designed for high-precision grinding and deburring operations.Equipped with Omron's advanced multi-axis control system and high-performance servo motors,it offers rapid response,precise control,and smooth operation.It is widely used for efficient grinding of complex parts such as die-cast components and machined parts.

LR-ZM5C-120:Five-Axis Intelligent Grinding Machine for Efficient and Precision Manufacturing

Product Overview

The LR-ZM5C-120 is a high-performance five-axis intelligent grinding machine designed for high-precision grinding and deburring operations.Equipped with Omron's advanced multi-axis control system and high-performance servo motors,it offers rapid response,precise control,and smooth operation.It is widely used for efficient grinding of complex parts such as die-cast components and machined parts.

Features

• Five-Axis Coordination

Movement along the X,Y,Z axes and rotation around the B and C axis allow multi-directional grinding with a single setup,reducing the number of setups and improving efficiency and precision.

• Rapid Tool Change

Equipped with a 4-6 head rotary tool library,it enables fast tool changes without a fixed tool change position and supports multi-angle inclined processing to meet diverse needs.

• Intelligent Operation

The user-friendly system can store tens of thousands of programs.One-click retrieval during product changeover eliminates the need for reprogramming,enhancing equipment utilization.

• Robust Structure

LR-ZM5C-120 main body is made of cast iron,providing high rigidity and machining stability.This design prevents tool vibration and ensures efficient grinding.

• Flexible Processing

Grinding tools can be easily replaced according to requirements,accommodating both flexible and rigid tools to meet different material and process needs.

• Convenient Fixtures

The worktable is equipped with quick-change locators for fixtures,enabling rapid fixture replacement and reducing tool setting and debugging time,thereby increasing production efficiency.

• Intelligent Compensation

The tool automatic compensation function extends tool life and reduces wear costs.

• Flexible Layout

LR-ZM5C-120 is easy to move and has a small footprint,making it convenient to adjust the workshop layout.

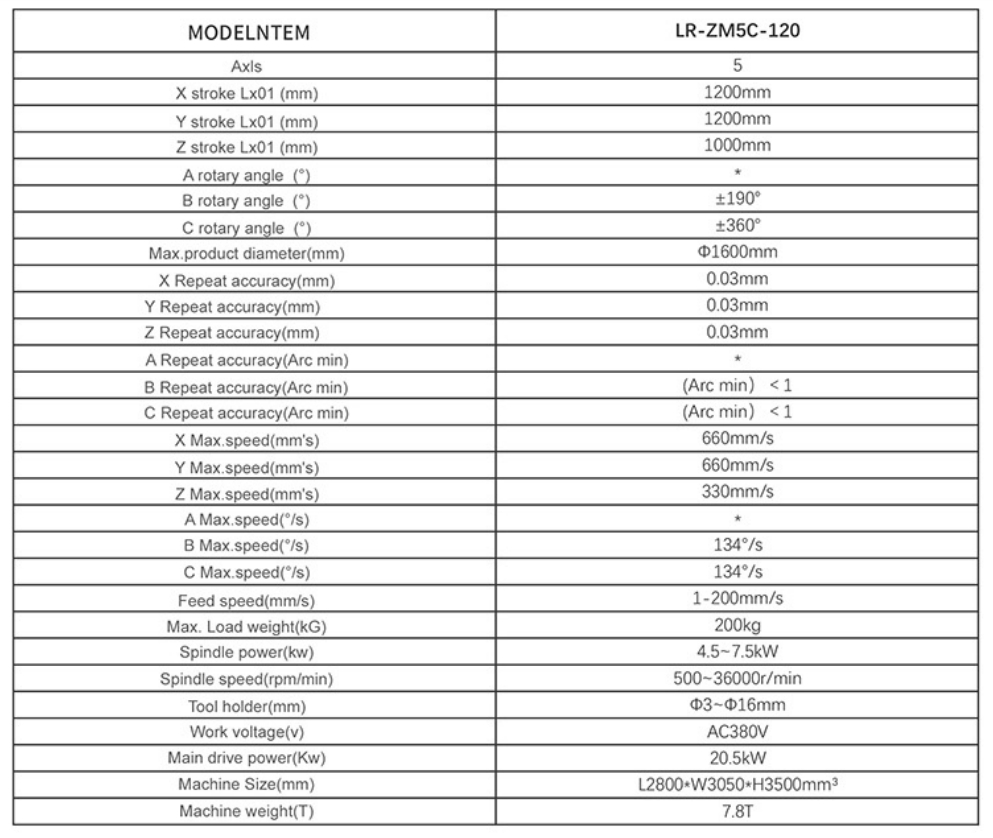

MAIN PARAMETERS

Advantages

High Efficiency:Five-axis coordination and rapid tool change significantly shorten processing cycles.

High Precision:Robust structure and precise control ensure high-quality grinding results.

Intelligent Operation:Program storage and quick retrieval reduce operational complexity and enhance user-friendliness.

Low Cost:Tool compensation and quick fixture change reduce tool wear and setup time.

Applications

Die-Casting Grinding:Suitable for multi-directional grinding and deburring of large die-cast components(e.g.,5G communication equipment,automotive brackets).

Automation Integration:Can be seamlessly integrated into automated production lines for unmanned grinding operations.

Manual Loading/Unloading:Supports manual operation,allowing a single operator to manage multiple machines,reducing labor costs.

The LR-ZM5C-120 is an ideal choice for the manufacturing industry to achieve efficient and precision grinding.It helps businesses optimize production processes and enhance competitiveness.