- Home >

- Products

Grinding machine

Polishing machine

Shot blasting machine

Die Casting Machine

Magnesium Alloy Thixomolding Machine

Automation Equipment

Hydraulic Machinery

Industrial Production Line and Machinery

Consumables

Furnace

-

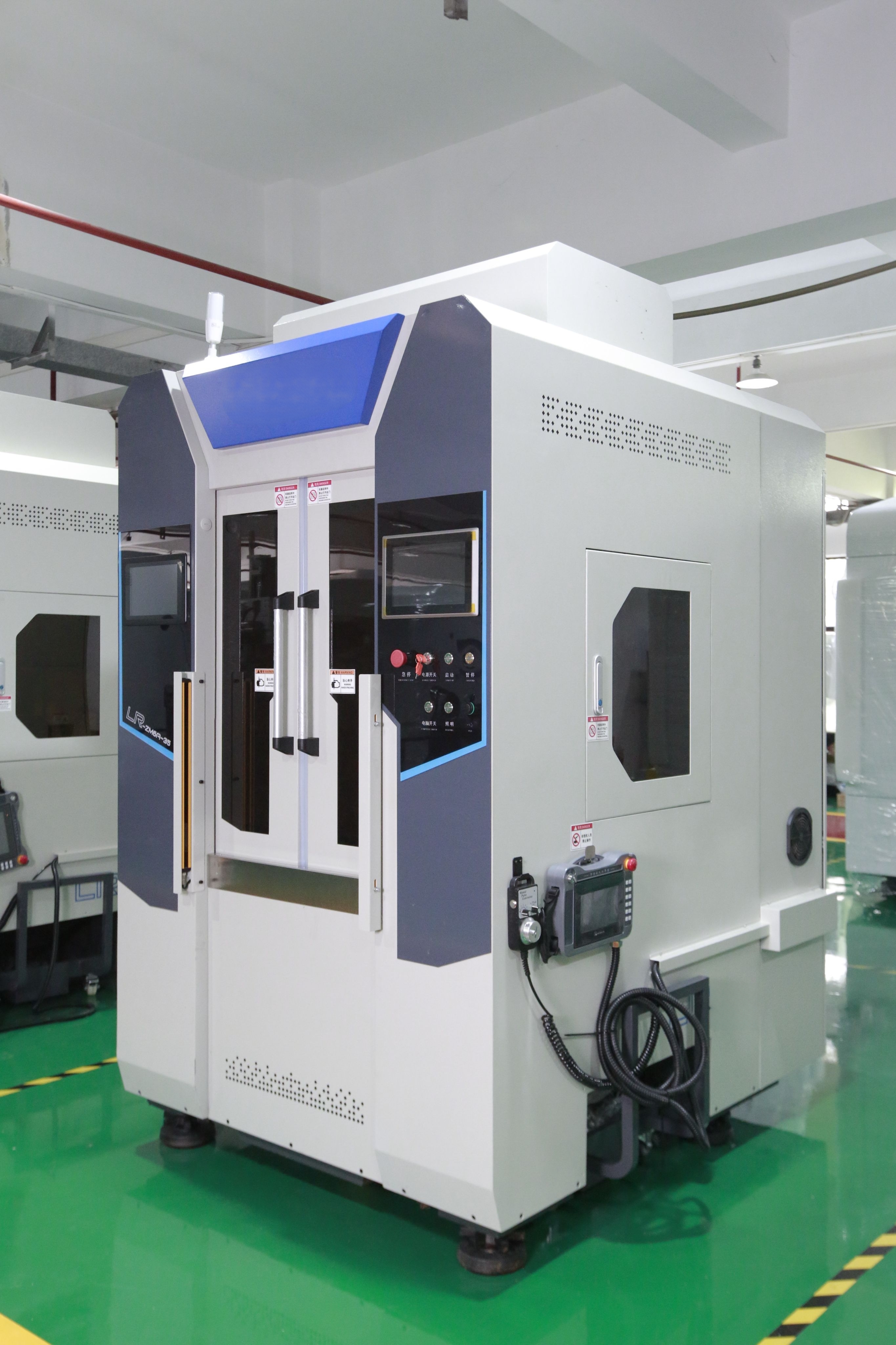

LR-ZM6C-35 Intellectual ability grinding machine

The 6-Axis deburring cell by DASEON redefines precision machining in space-constrained manufacturing environments,it combines agility with industrial-grade accuracy.

-

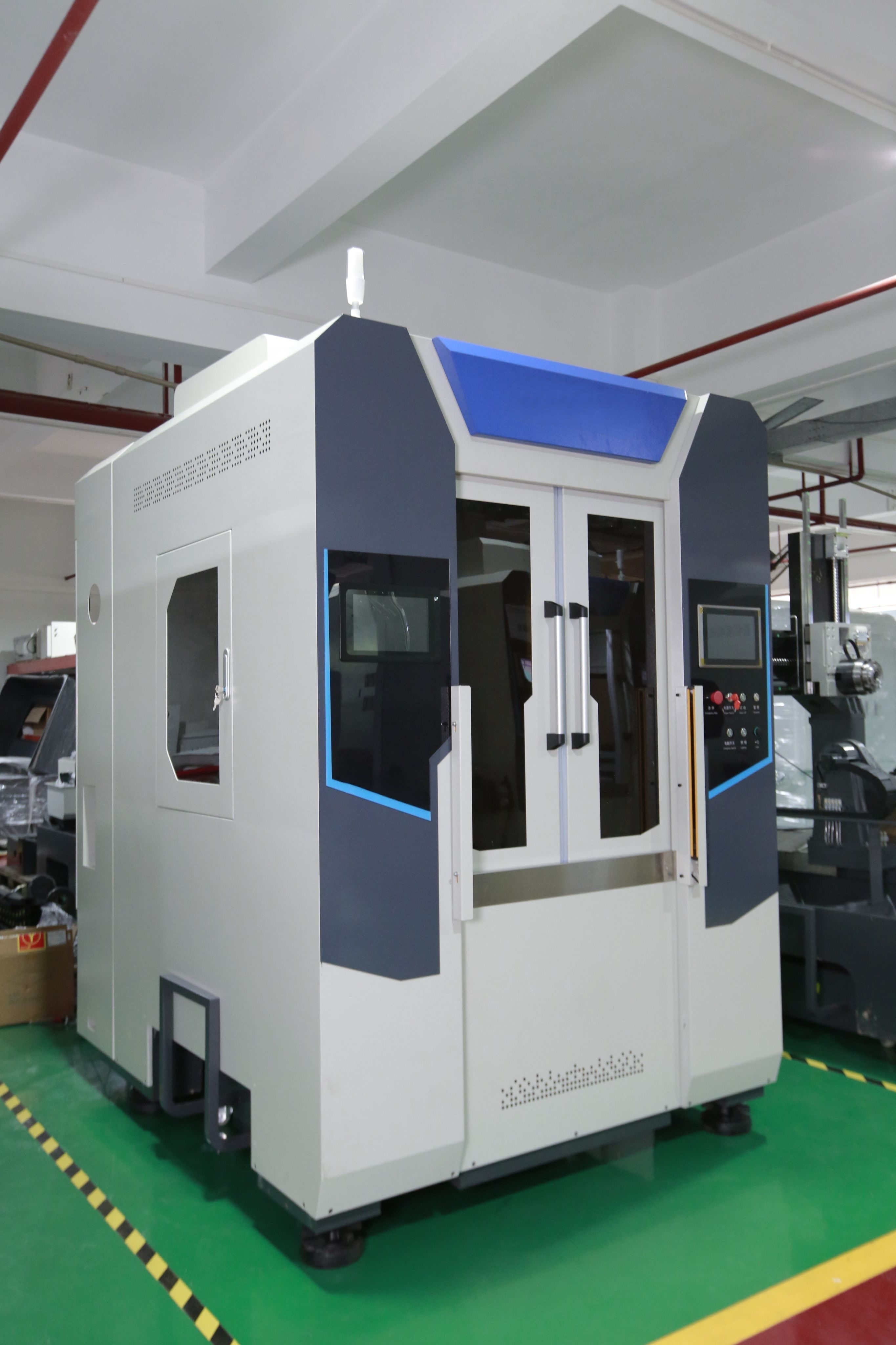

LR-ZM6C-65 Intellectual ability grinding machine

Designed to cater to mid - scale production needs, this Mid - Scale Deburring System offers a comprehensive solution for industries requiring consistent quality and efficient deburring processes.

-

LR-ZM6C-90 Intellectual ability grinding machine

Engineered to meet the challenges of large - scale production, this Large - Format Deburring Equipment offers unrivaled performance for industries where size and reliability are paramount.

-

LR-ZM6B-35 Intellectual ability grinding machine

Equipped with SYNTEC’s multi-axis control and advanced thermal compensation, this system excels in processing automotive transmissions, aerospace brackets, and e-mobility components. Its modular tooling and MES integration streamline workflows, cutting cycle times.

-

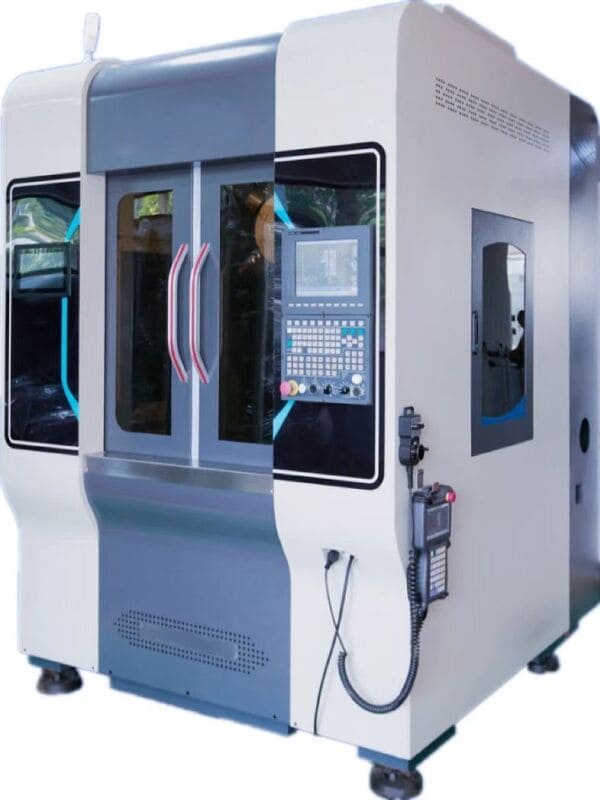

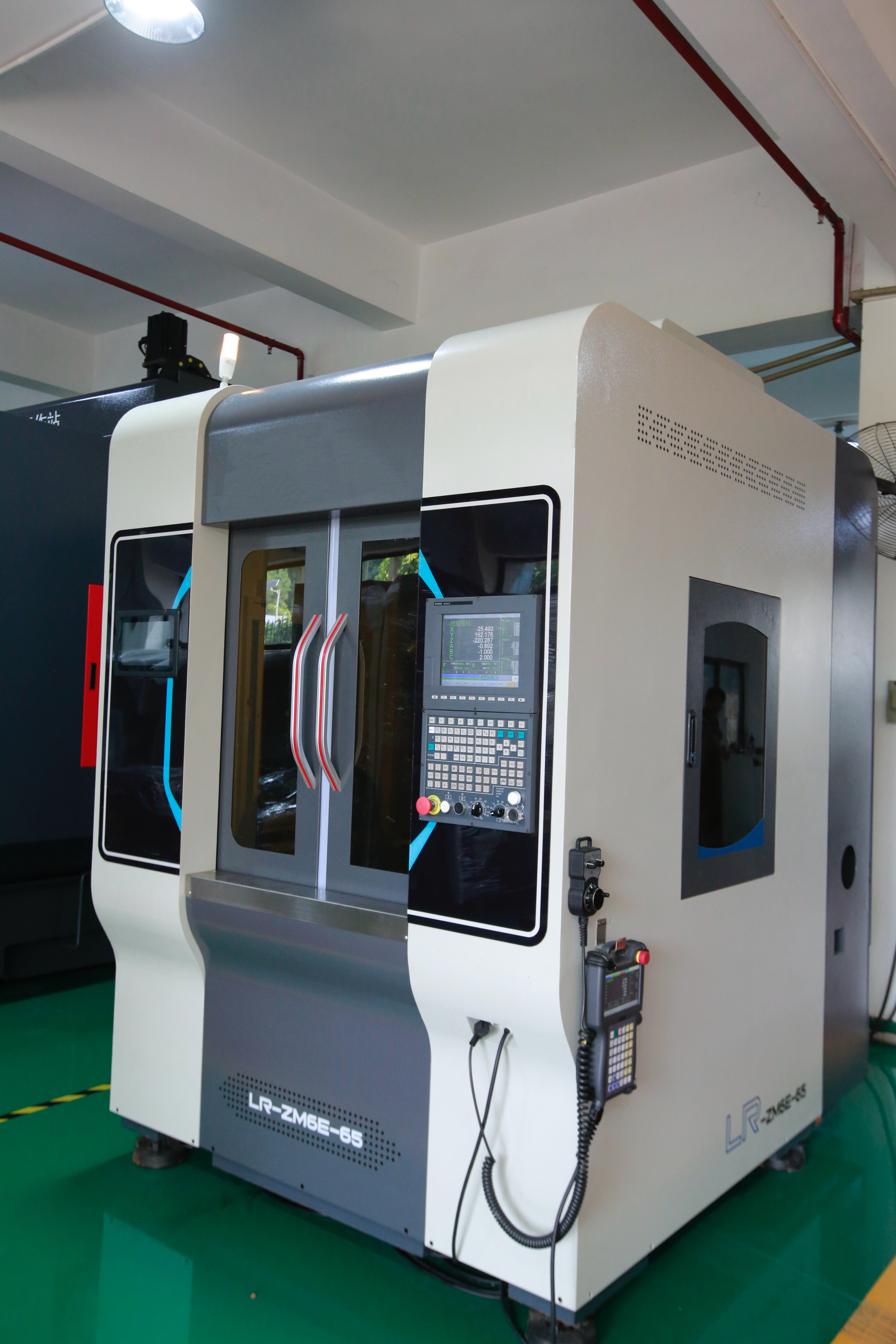

LR-ZM6B-65 Intellectual ability grinding machine

The Mid-Scale Deburring System by DASEON is the definitive solution for manufacturers seeking precision, flexibility and scalability. With SYNTEC’s advanced 6-axis control, rapid tooling adaptability, and compliance with global standards, this system streamlines workflows while maintaining rigorous quality benchmarks. From automotive transmissions to aerospace brackets, the LR-ZM6B-65 empowers industries to achieve higher throughput, lower operational costs, and consistent micron-level accuracy.

-

LR-ZM6B-90 Intellectual ability grinding machine

Traditional solutions struggle with the dual requirements of high-capacity workpiece handling and precision tolerances, leading to inefficiencies in both quality and productivity. The LR-ZM6B-90 High-Capacity Deburring Machine addresses this gap.

-

LR-ZM5C-120 automatic grinding machine

The LR-ZM5C-120 is a high-performance five-axis intelligent grinding machine designed for high-precision grinding and deburring operations.Equipped with Omron's advanced multi-axis control system and high-performance servo motors,it offers rapid response,precise control,and smooth operation.It is widely used for efficient grinding of complex parts such as die-cast components and machined parts.

-

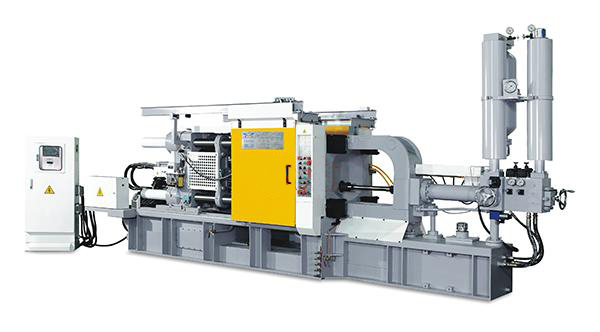

Compact Series Cold Chamber Die Casting Machine

In the competitive die casting landscape, Compact series Cold Chamber Die Casting Machine,those clamping forces spanning 1600-3000kN emerge as the cornerstone for small - to - medium enterprises (SMEs) and startups.

-

General-Precision Series Cold Chamber Die Casting Machine

For industries demanding consistent quality and versatility, our General-Precision Series Cold Chamber Die Casting Machines (4000-8000kN) combine advanced engineering with intelligent controls.