Toothpaste Production Line

Brand :CAREER

Product origin :China

Delivery time :20 days after receiving down payment

Supply capacity :10 lines /month

The line mainly applied in such industries as daily chemical care products, cosmetics, cream lotion, gel, toothpaste, biopharmacutical industry, food industry, paint and ink , nanometer materials, petrochemical.

Hydraulic lifting emulsifier toothpaste making machine means that when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect. By the operation of hydraulic sheraing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be disperesed and emulsifed instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

The line mainly applied in such industries as daily chemical care products, cosmetics, cream lotion, gel, toothpaste, biopharmacutical industry, food industry, paint and ink , nanometer materials, petrochemical.

Item | MixerKW | Disperser | Main pot heater | Water pot heater | Oil pot heater | Water pot mixer | Oil pot mixer | Vacuum pump | Hydraulic |

50L | 1.1 | 2.2kw | 3kw | 6kw | 3kw | 0.37kw | 0.37kw | 0.75kw | 0.75kw |

100L | 2.2 | 4kw | 6kw | 6kw | 6kw | 0.55kw | 0.55kw | 1.5kw | 0.75kw |

200L | 3 | 5.5kw | 9kw | 12kw | 9kw | 0.75kw | 0.75kw | 1.5kw | 1.1kw |

300L | 4 | 5.5kw | 9kw | 12kw | 12kw | 1.1kw | 1.1kw | 2.2kw | 1.5kw |

500L | 4 | 7.5kw | 12kw | 18kw | 18kw | 1.5kw | 1.5kw | 2.2kw | 1.5kw |

1Ton | 5.5 | 11kw | 18kw | 18kw | 18kw | 2.2kw | 2.2kw | 4kw | 2.2kw |

2Ton | 7.5 | 15kw | 27kw | 27kw | 27kw | 3kw | 2.2kw | 4kw | |

3Ton | 11 | 18kw | 36kw | 36kw | 36kw | 4kw | 3kw | 5.5kw |

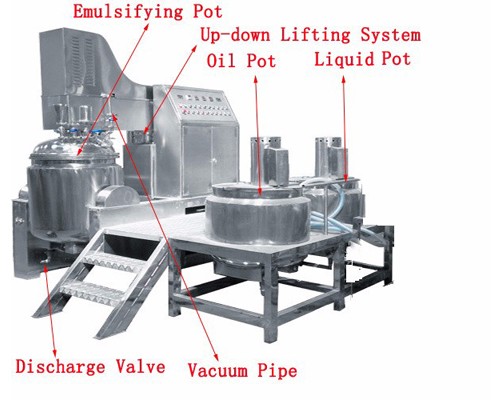

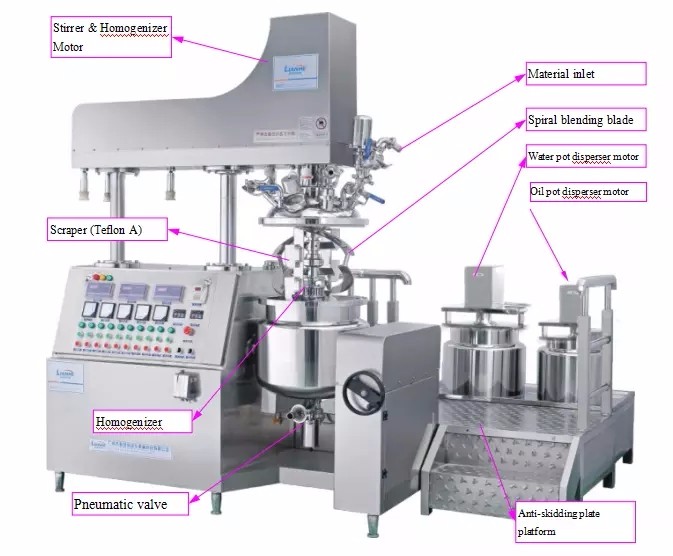

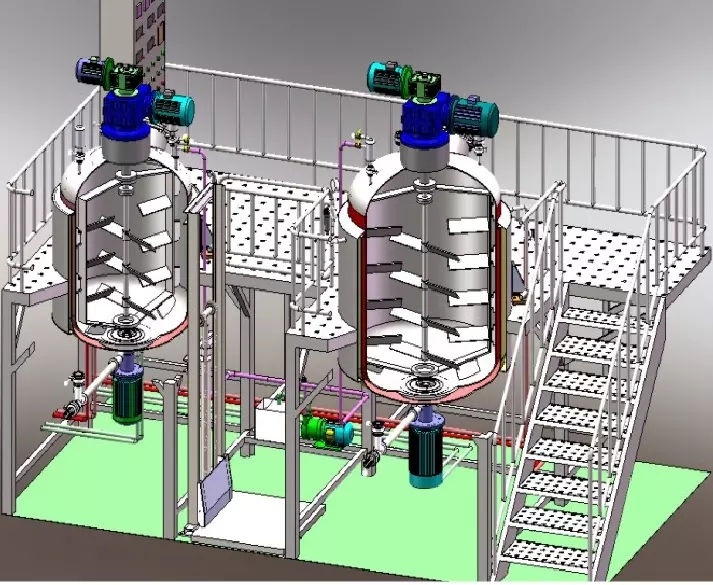

Main structure: toothpaste production line, toothpaste making machine

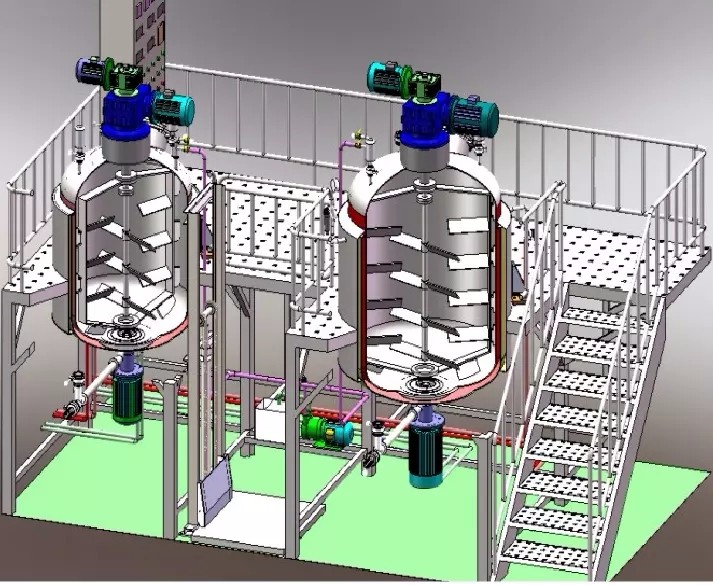

Main pot (vacuum emulsifying mixing), Water and oil pot, Vacuum system, Electric control system / PLC touch screen, Operation platform

No | Name | Configuration |

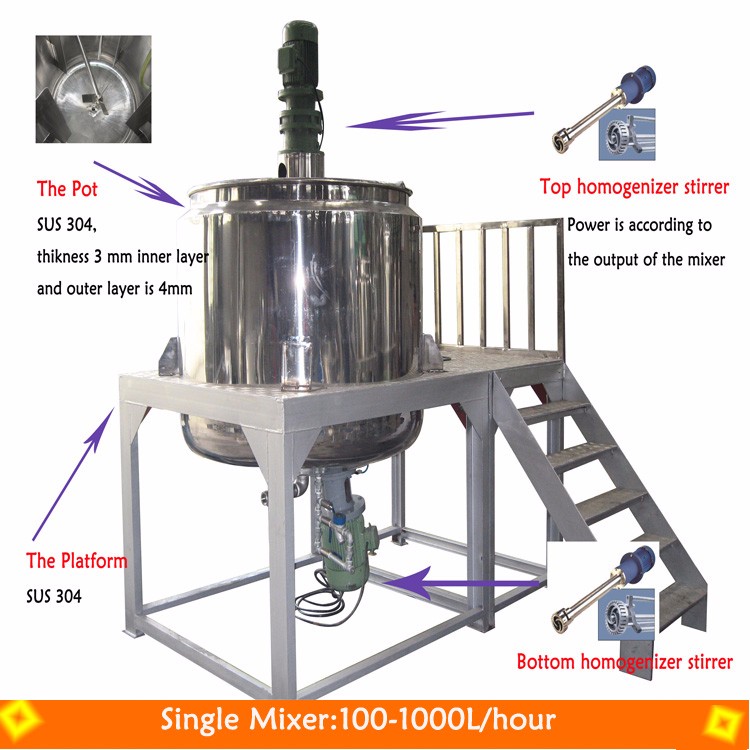

1 | Main Pot | a.3 layers structure; b.300-3000L c.All use stainless steel; d.Steam heating or electric heating; e.Polished out and in; f.Mechanical seal; g.Pneumatic butterfly valve to control pot lid; h.Vacuum pressure meter, material sucking filter; breather, vacuum port; pressure input port(with filter); spot light; sight-glass and wiper; manhole, spice funnel, CIP clean port. |

2 | Homogenizer | a.High shearing b.316L |

3 | Mixer | a.Inverter to control speed; b.Motor reducer; c.Mixing paddle; d.Scraper: Teflon |

4 | Two pre-Mixing pot | a.316L b.Pre-mix pot c.Use pneumatic valve to control; d.Discharge valve. |

5 | Control System | a.Electric control; b.User interface with real-time reflection parameters and status: homogeneous speed value, stirring speed, out of the water and steam temperature, the temperature of the material in real time, regular time, fault display and tips, pneumatic pipe valve status. |

6 | Lid Lift System | a.Optional; b.Hydraulic lifting system:with solenoid valve, choke-flow valve, single-way valve; the system install up and down limit device and anti-rush top device to make lifting stable, safe and reliable. |

7 | Vacuum System | a.Vacuum pump; b.Buffer tank; c.Vacuum pipe. |

8 | Platform | a.All cover by stainless steel with sanitary flashing slot on the surface, edge seamless whole slip, stairs with handrails at both ends, with a crosspiece slip. |

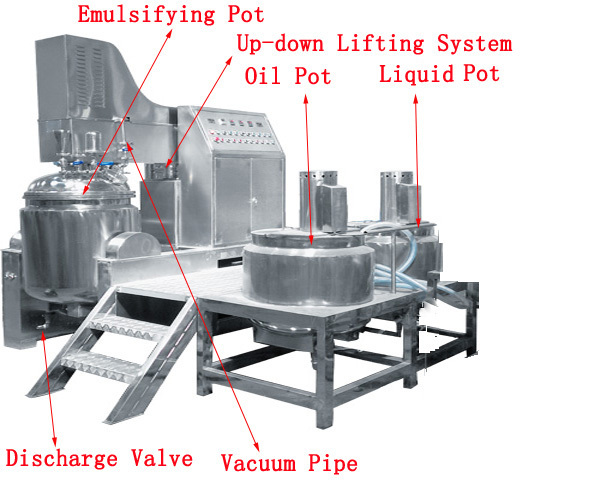

2: Process Flow

a. Water,oil and others ,heated and mixed in Liquid Pot and Oil Pot.

b. Materials ,Sucked into emulsifying pot by vacuum system

c. Stirred by both the center blade and side scraper. Then cut off in cut-off mixing unit,all in the Emulsifying Pot.

d. The materials are finally crushed into small pellets of 200um~2um.

e. The finished product , pumed out from Discharge System

3: Features

a.Cover can be lifted up-down by lifting system

b.With wheels,movable

c.The bubbles (generated during stirring and mixing process), sucked out from material,because of Vacuum Effect

d.Machine Materials,ss304.And ss316 or ss316L according to the requirement of Corrosion Resistance

4: Application

5: Customer site

After-Sales Service

1, Warranty Time: one year, within this period if spare parts damage except the wrong operation , seller supply spare parts for free.We can send technician overseas for debugging machine, buyer should be responsible for necessary fee.

2, Commissioning Services: During the time of installation and debugging, our engineers will not leave, until you are satisfied with the machine.

3, Training Services: Our engineer will train your staff installation and commissioning, operation during this period if necessary.And they will not be leave until your staff can operate properly.

4, Maintenance Services: As soon as we receive your inquiry about fault, we will reply you within 24 hours

5, Lifelong Services: We provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

6, Certificate Services: we can provide certificates to customers

7,Inspection Services: Accept the third party inspection company or inspectors check the products before shipment

8,File Services: we can supply Manual Specification,Operate Video and other files you need.

More Product Information,please contact supplier !