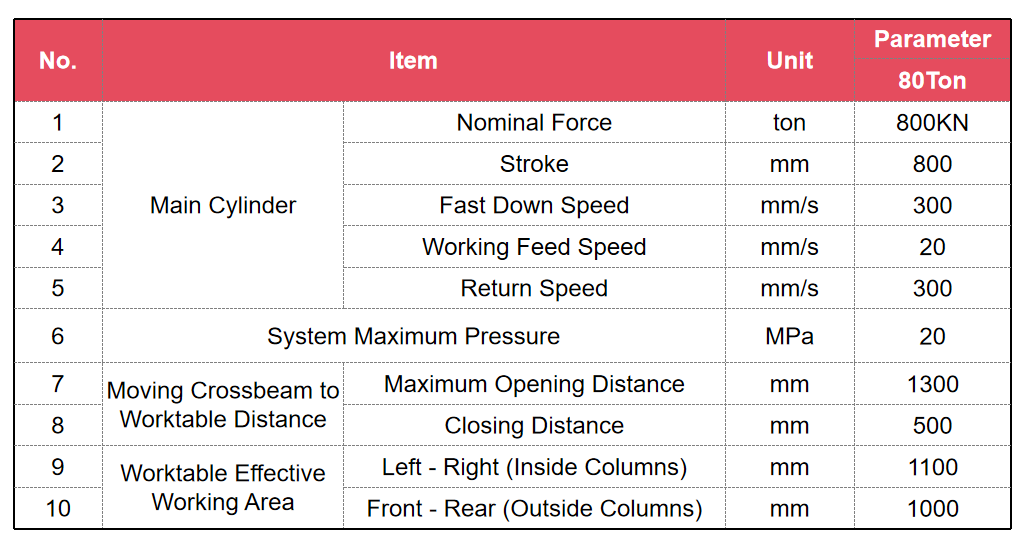

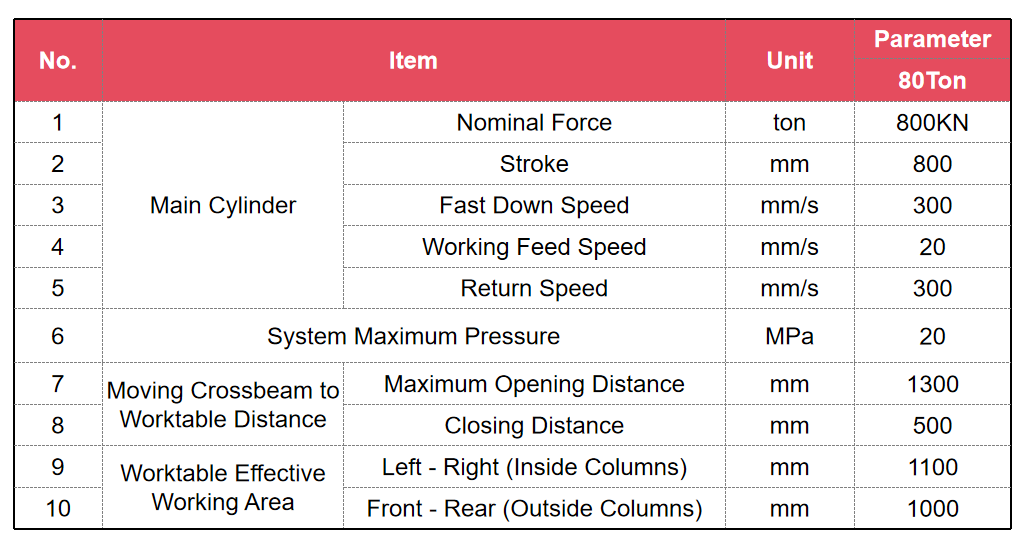

The 80Ton hydraulic forming press is a high-performance machine engineered to deliver 800KN of controlled force, designed for heavy-duty material processing in industries such as automotive manufacturing, heavy equipment production, and composite materials fabrication.

This hydraulic forming press serves as the premier model in its product range, exhibiting exceptional performance in deep drawing operations, thick-gauge material trimming, and high-pressure composite molding. Offering a seamless blend of robust force and meticulous precision, it efficiently processes diverse materials including plastic sheets, metal plates, and fiber-reinforced composites. Engineered to meet the rigorous demands of modern industrial manufacturing, this press stands as an indispensable solution in applications where reliability, dimensional accuracy, and material adaptability are critical success factors.

With a defining characteristic of 800KN (80 metric tons), this hydraulic forming press is engineered to process heavy-gauge materials while maintaining the precision required for complex geometric forming—essential for applications ranging from automotive chassis components to industrial machinery parts.

Operating at 20MPa (adjustable in 0.5MPa increments), the press achieves ±0.2% pressure stability via a proportional pressure valve, ensuring uniform material deformation across all forming cycles—a distinct technical advantage over mechanical alternatives.

Featuring an 800mm stroke, the press allows for deep drawing of up to 400mm, accommodating tall molds and enabling the production of large-scale components— a key advantage in industries demanding deep and precise material deformation.

The 1200x1000mm (LxW) workspace offers a generously sized platform for multi-cavity tooling or oversized workpieces, optimizing high-volume production efficiency as a core design feature of this hydraulic forming press.

A maximum open height of 1300mm enables straightforward installation of tall molds and handling of high-clearance workpieces in heavy-duty applications, making the press well-suited for intricate tooling configurations.

Powered by a 22KW three-phase motor, the press achieves rapid approach/return speeds of 300mm/s, with an adjustable working feed speed that ensures controlled material engagement—an essential feature for preventing tearing in thick or brittle materials.

The adjustable dwell time (0–24 hours) supports diverse applications, including thermoset resin curing, stress relief in metal forming, and dimensional stabilization in composite molding, greatly enhancing the press’s adaptability to varied manufacturing processes.

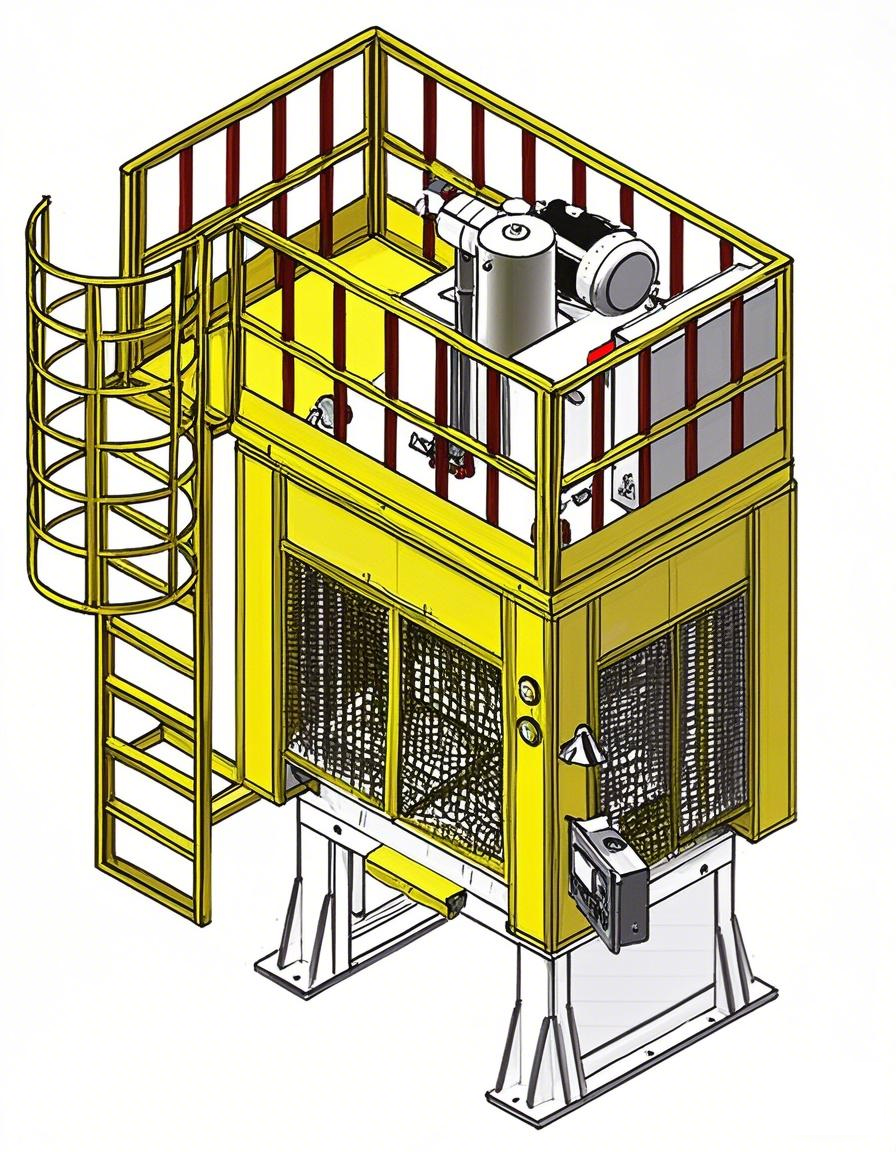

The hydraulic forming press is meticulously engineered with a fortified four - post three - plate framework.

This structural design incorporates heavy - duty steel columns and stress - relieved platens, which are specifically crafted to mitigate frame deflection under the full 800KN load. By effectively minimizing deformation, the press ensures unwavering long - term rigidity and delivers a consistently high - performance output. This outstanding feature stands as a prime example of the press's robust and enduring construction, setting a high standard in the industry.

The hydraulic forming press is outfitted with a precisely adjustable motorized die height mechanism. This mechanism offers a well - defined adjustment range, facilitating swift and accurate mold changeovers.

The ability to make rapid and precise height adjustments significantly enhances the press's adaptability in mixed - production settings. It allows for seamless transitions between different tooling setups, making it an indispensable asset for manufacturers dealing with a wide array of tooling requirements. This functionality not only boosts operational efficiency but also positions the press as a versatile solution in the dynamic manufacturing landscape.

The 80Ton hydraulic forming press stands as an epitome of heavy-duty industrial precision, integrating 800KN of consistent force with cutting-edge technology and a rugged mechanical design. As a pivotal model within the hydraulic forming press lineup, it enables manufacturers in automotive, heavy machinery, and renewable energy industries to process robust materials with precision and operational efficiency. Its innovative technical features, minimal maintenance requirements, and adherence to international standards position it as a vital asset in modern manufacturing, establishing a benchmark for performance in high-load forming operations. For sectors demanding excellence in both force application and dimensional accuracy, this hydraulic forming press offers unmatched dependability and adaptability, ensuring optimal results even in the most stringent production environments.