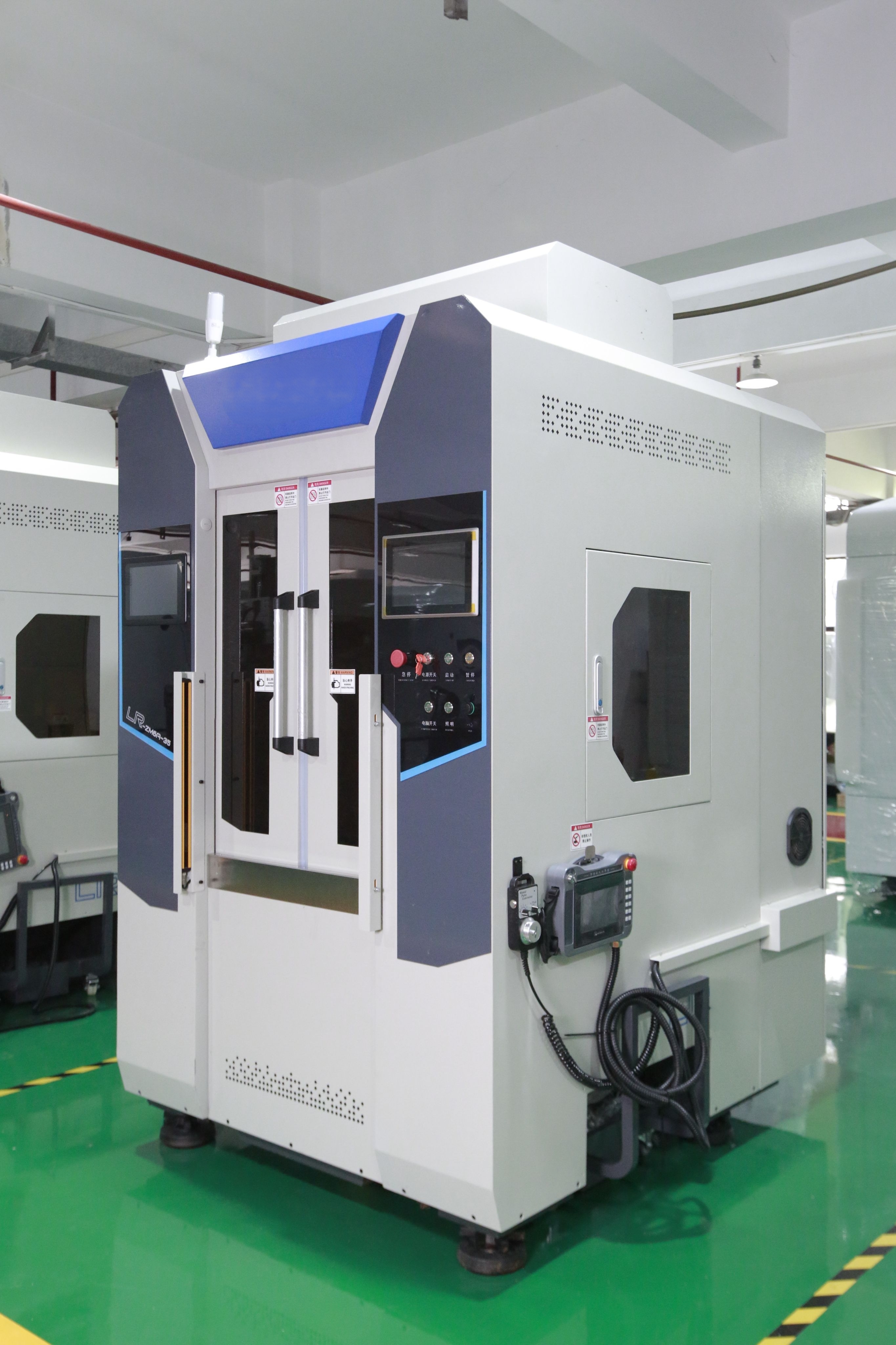

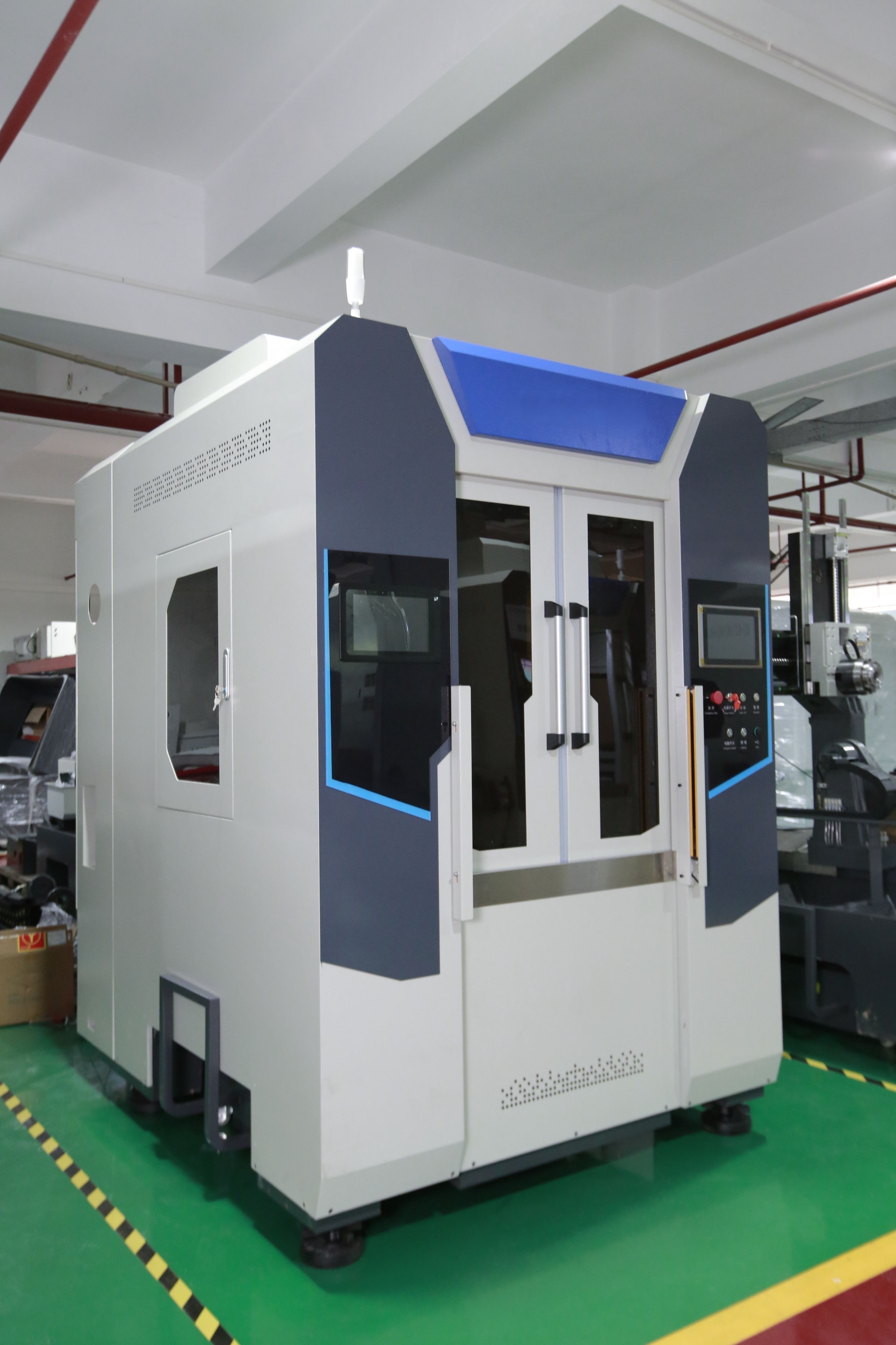

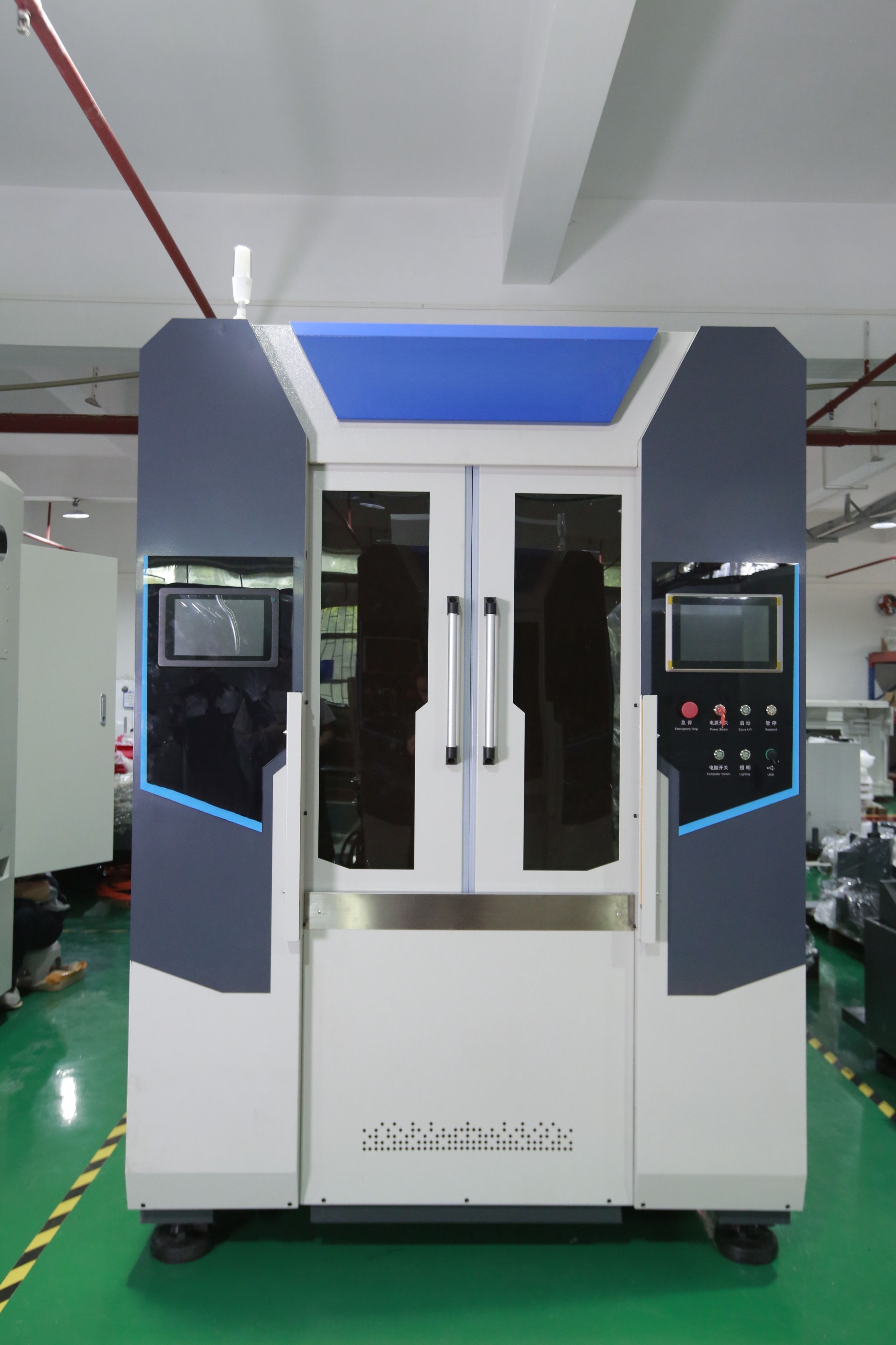

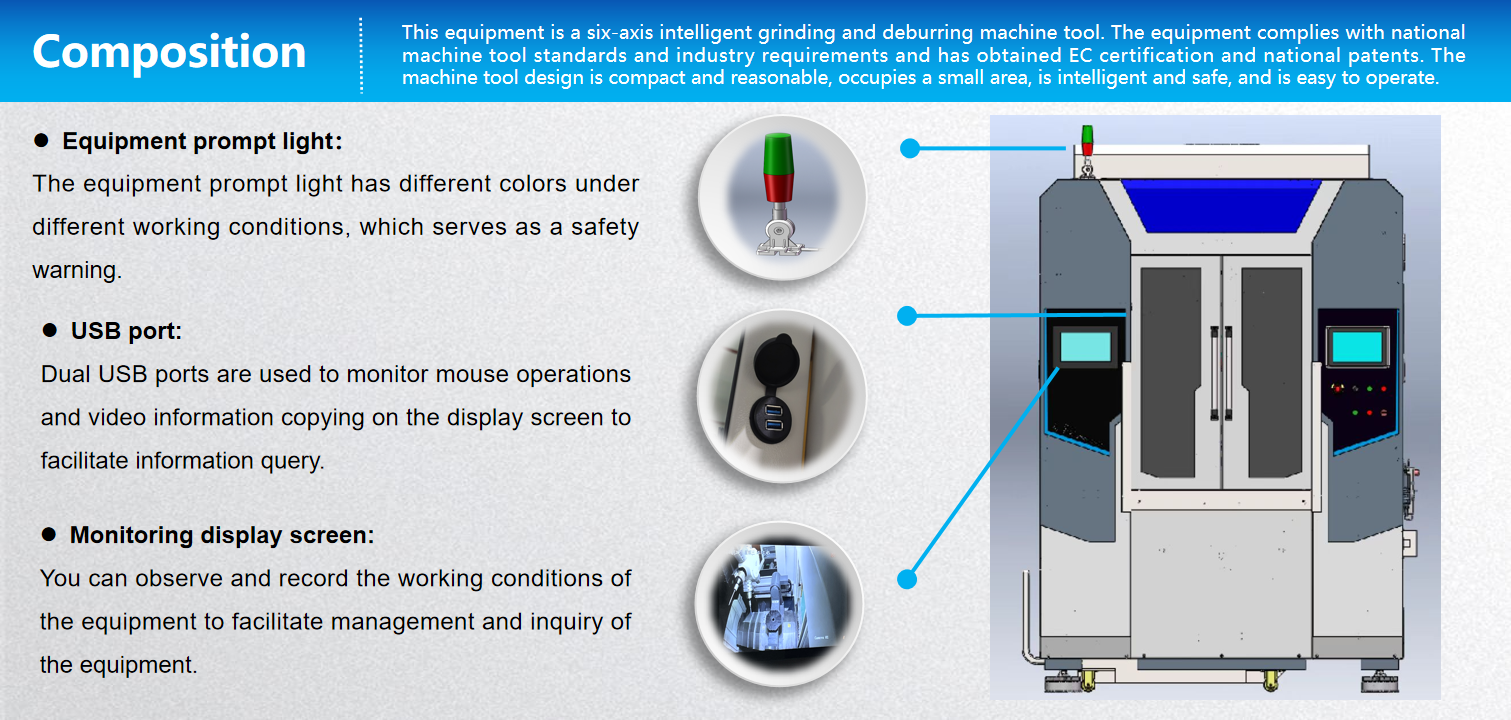

LR-ZM6C-35 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The 6-Axis deburring cell by DASEON redefines precision machining in space-constrained manufacturing environments,it combines agility with industrial-grade accuracy.

In the dynamic landscape of industrial automation, the LR - ZM6C - 35 Deburring Machine, a leading Compact Deburring Solution, emerges as a pivotal solution for businesses seeking to balance space constraints with uncompromising precision. Tailored for small to medium - sized workpieces, this Compact Deburring Solution is not just a tool but a strategic asset for industries where every millimeter of space and every micron of precision matters.

Key Features

1.Ultra-Compact, High-Mobility Design

Dimensions: 1,450mm (L) × 1,750mm (W) × 2,450mm (H); weight 2,000kg.

Work Envelope: X/Y/Z strokes of 350mm/350mm/440mm, supporting components up to Φ500mm in diameter and 35kg in weight.

Mobility: Equipped with reinforced casters and forklift-compatible base, this Compact Deburring Solution can be repositioned within minutes, ideal for dynamic workshop layouts.

2.Micro-Scale Precision Engineering

Repeat Accuracy: ≤0.02mm (X/Y/Z axes), <1 arc minute (A-axis), and ≤10 arc seconds (B/C axes), ensuring consistency for intricate features such as Ø3–8mm cross-holes and R0.5 fillets.

Hybrid Spindle Technology: Combines rigid and floating spindles (3–16mm tool diameter) to eliminate secondary damage in thin-walled components (reduced to <5%), surpassing manual deflashing quality (Cpk >1.67 vs. manual Cpk <1.0).

Vision-Assisted Calibration: Integrated 2D/3D vision systems automatically correct workpiece positioning errors (±0.01mm), critical for medical implants and micro-electronics.

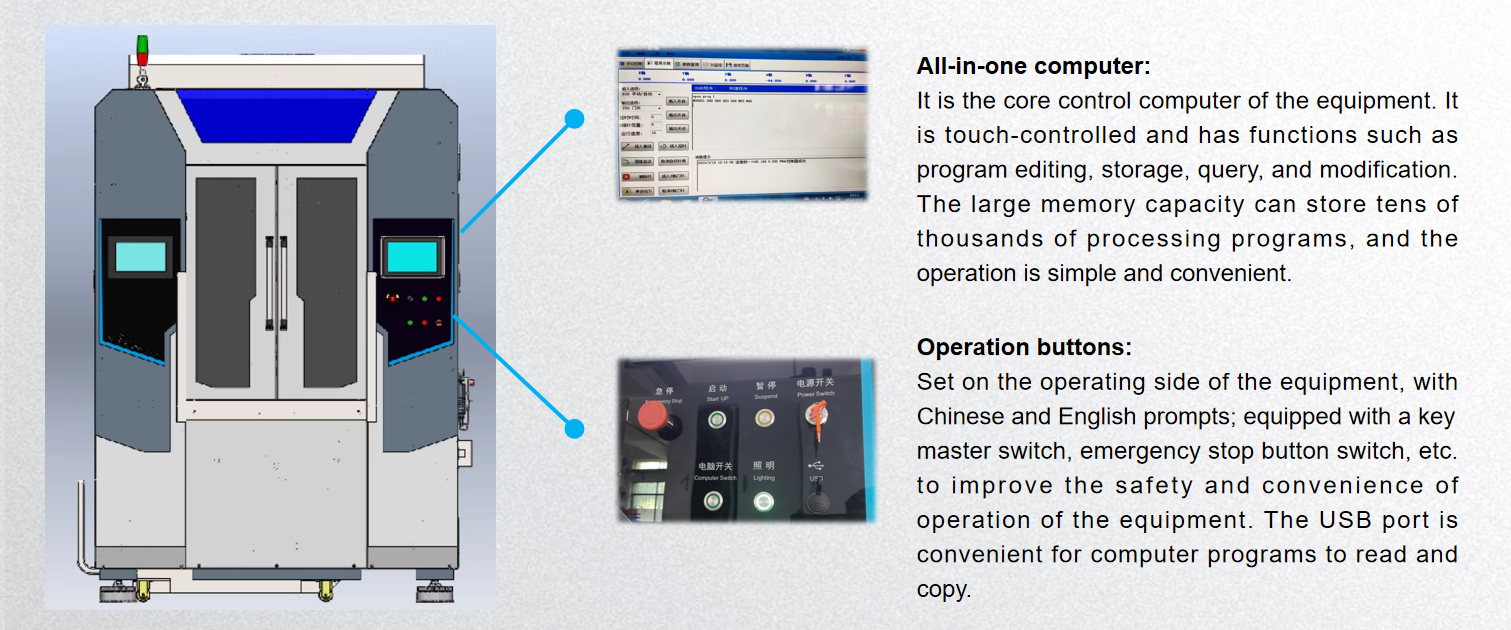

3.Smart Automation & User-Centric Controls

OMRON Control System: Features 6-axis linkage for complex 3D trajectories, with A/B/C rotary axes achieving ±110° (A-axis) and ±190° (B-axis) for multi-angle operations.

Toolpath Optimization: Minimize redundant motions, achieving 120–150 parts/hour throughput at 700mm/s axis speed—3–5x faster than manual methods.

Dual-Mode Operation: Switch between batch processing and single-piece prototyping without reprogramming, enhancing flexibility for high-mix production.

4.Energy Efficiency & Sustainability

Closed-Loop Dust Management: Captures and recycles 30% of particulate waste, reducing disposal costs.

Low-Power Mode: Reduces energy consumption by 25% during standby (total driving power: 14kW), with optional water curtain filtration systems for hazardous material compliance.

Safety Enhancements: Fully enclosed structure with emergency stop protocols, smoke detection, and fire suppression capabilities.

Space - Saving Design for Agile Operations

Measuring 1450×1750×2450mm and weighing 2T , Its compact footprint fits effortlessly into tight production layouts, whether beside an injection molding machine or within an automated cell. With a platform load weight of 35kg, it’s designed to handle small to medium - sized workpieces with ease. By bringing deburring and grinding operations right to the point of production, it eliminates the need for extensive material handling, reducing costs and minimizing workpiece damage. This is particularly crucial in electronics manufacturing, where small components require immediate post - molding processing to maintain quality.

Industry Applications: Where Precision Meets Practicality

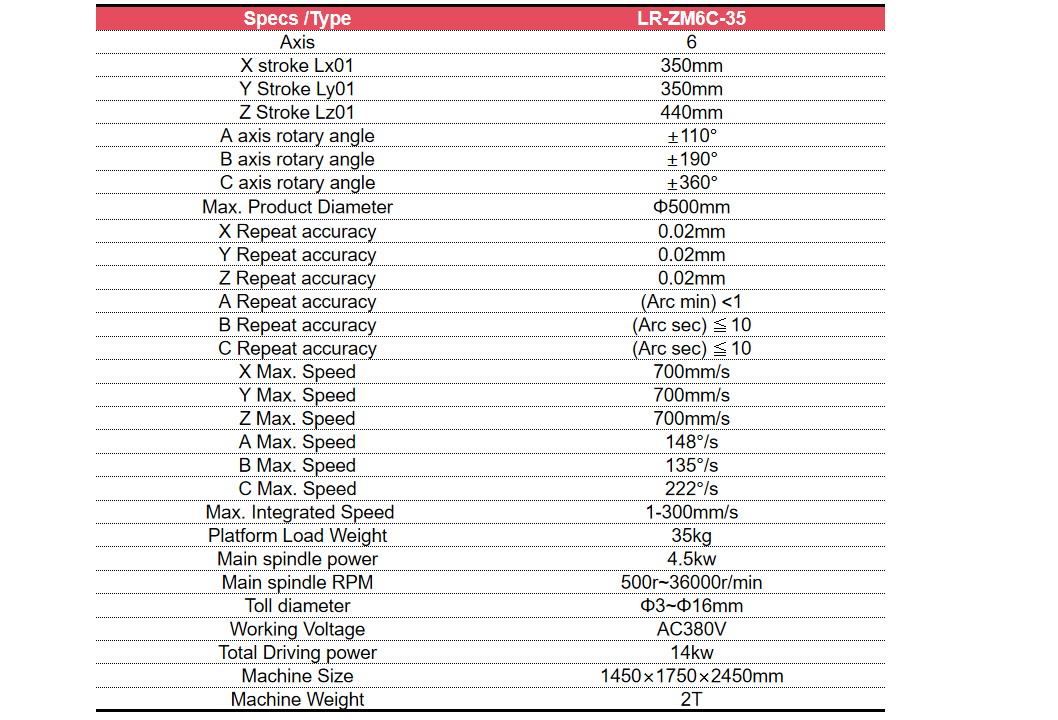

Parameter

The LR - ZM6C - 35 Deburring Machine, a top - tier Compact Deburring Solution, is more than just equipment; it’s a testament to innovation that empowers manufacturers to achieve precision without compromising on space or efficiency.