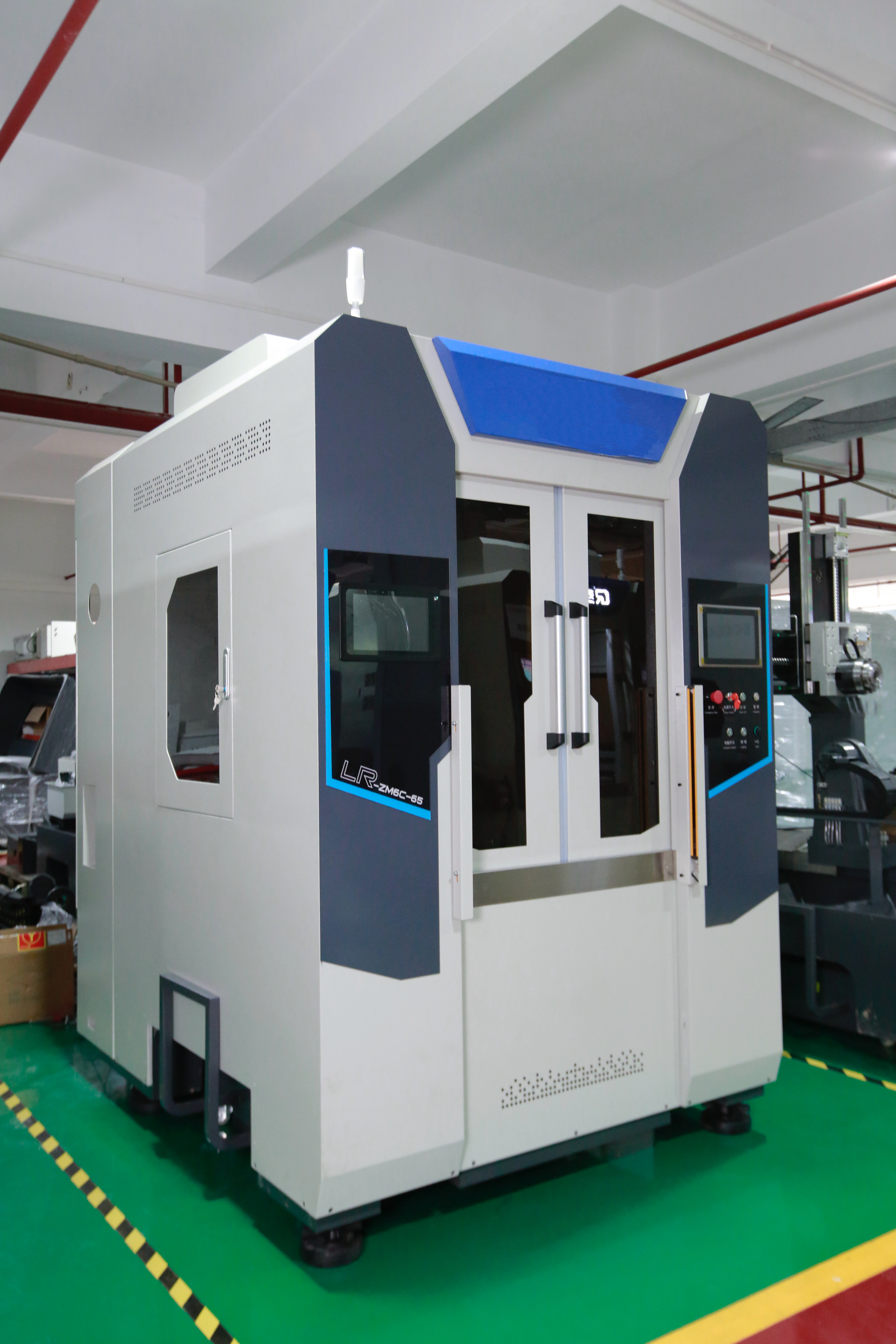

LR-ZM6C-65 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

Designed to cater to mid - scale production needs, this Mid - Scale Deburring System offers a comprehensive solution for industries requiring consistent quality and efficient deburring processes.

In the competitive landscape of industrial manufacturing, the LR - ZM6C - 65 Deburring Machine, a distinguished Mid - Scale Deburring System, emerges as the perfect balance between power and precision for medium - sized workpieces.

Key Features

1.Expanded Work Envelope & Load Capacity

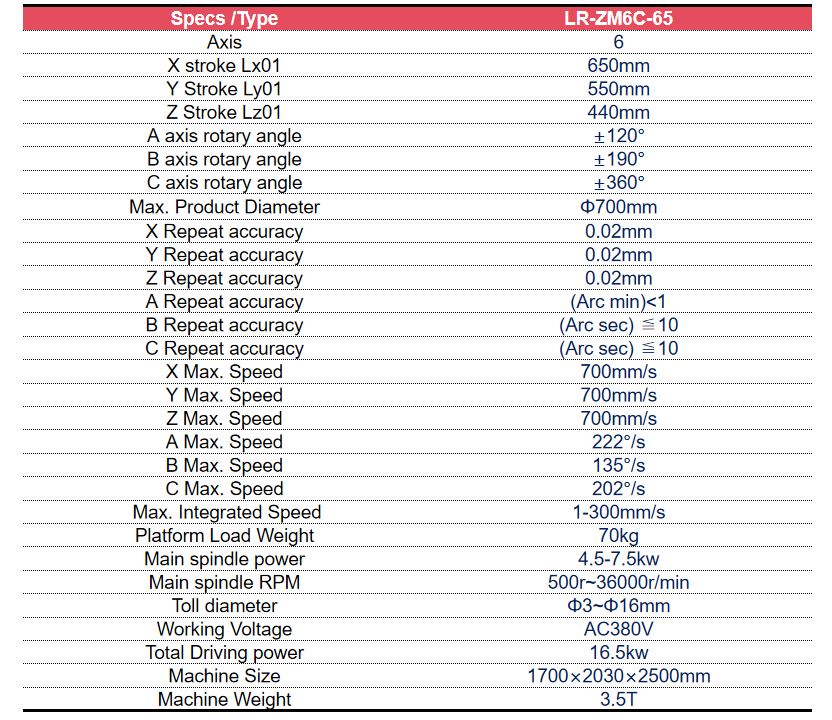

Dimensions: 1,700mm (L) × 2,030mm (W) × 2,500mm (H); weight 3,500kg.

Work Envelope: X/Y/Z strokes of 650mm/550mm/440mm, supporting components up to Φ700mm in diameter and 70kg in weight.

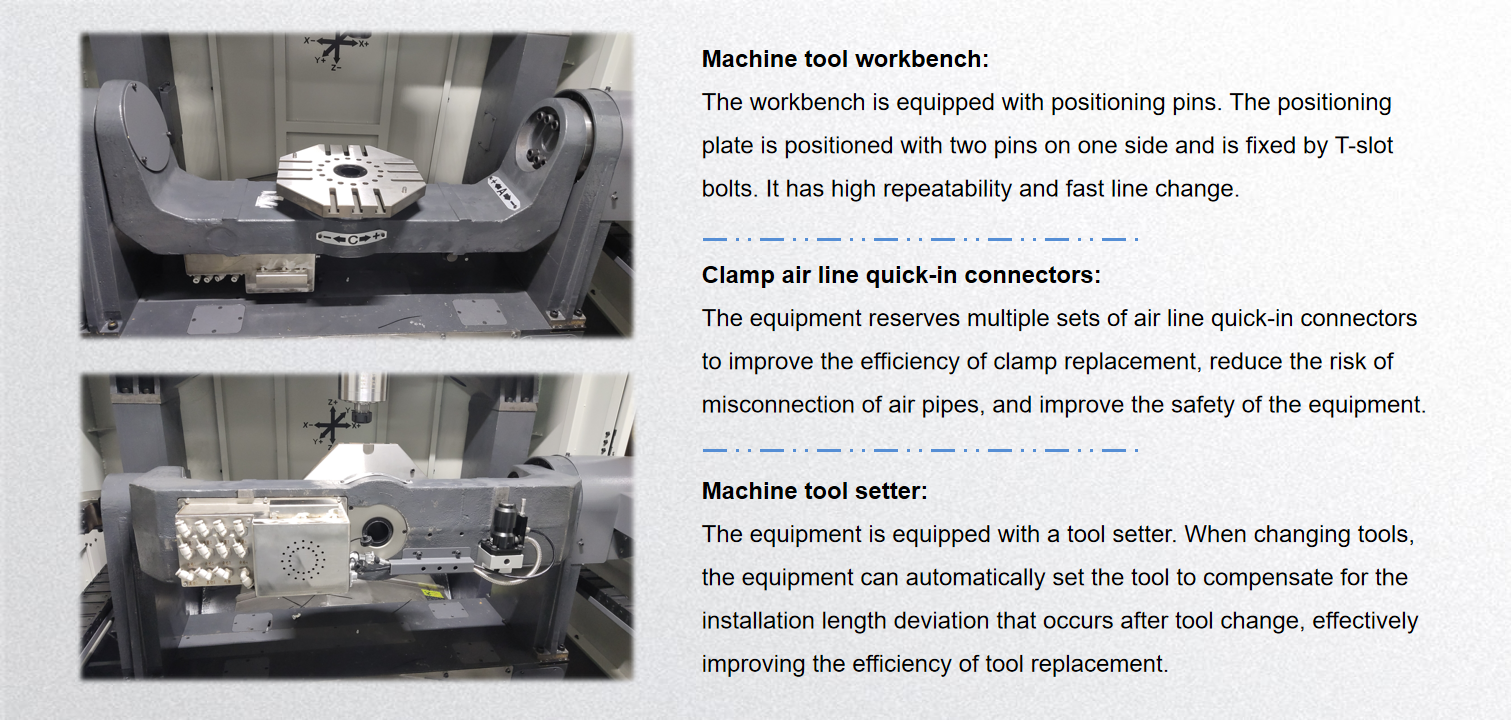

Modular Tooling: V6axis smart tool changer enables 7–9 automatic tool swaps per cycle, critical for multi-cavity molds.

2.Precision for Complex Geometries

Repeat Accuracy: ≤0.02mm (X/Y/Z axes), <1 arc minute (A-axis), and ≤10 arc seconds (B/C axes), ensuring uniformity in threaded ports and sealing surfaces.

Thermal Stability: Real-time spindle temperature control (4.5–7.5kW power range) minimizes deformation in aluminum and zinc alloys during prolonged operations.

Fillet Optimization: Processes R0.5–R2.0 transition zones with Ra ≤1.0μm finishes, eliminating manual rework.

3.High-Speed Automation

Axis Speed: 700mm/s (X/Y/Z) and 222"/s (A-axis), achieving 200–250 parts/hour throughput—70% faster than manual deburring.

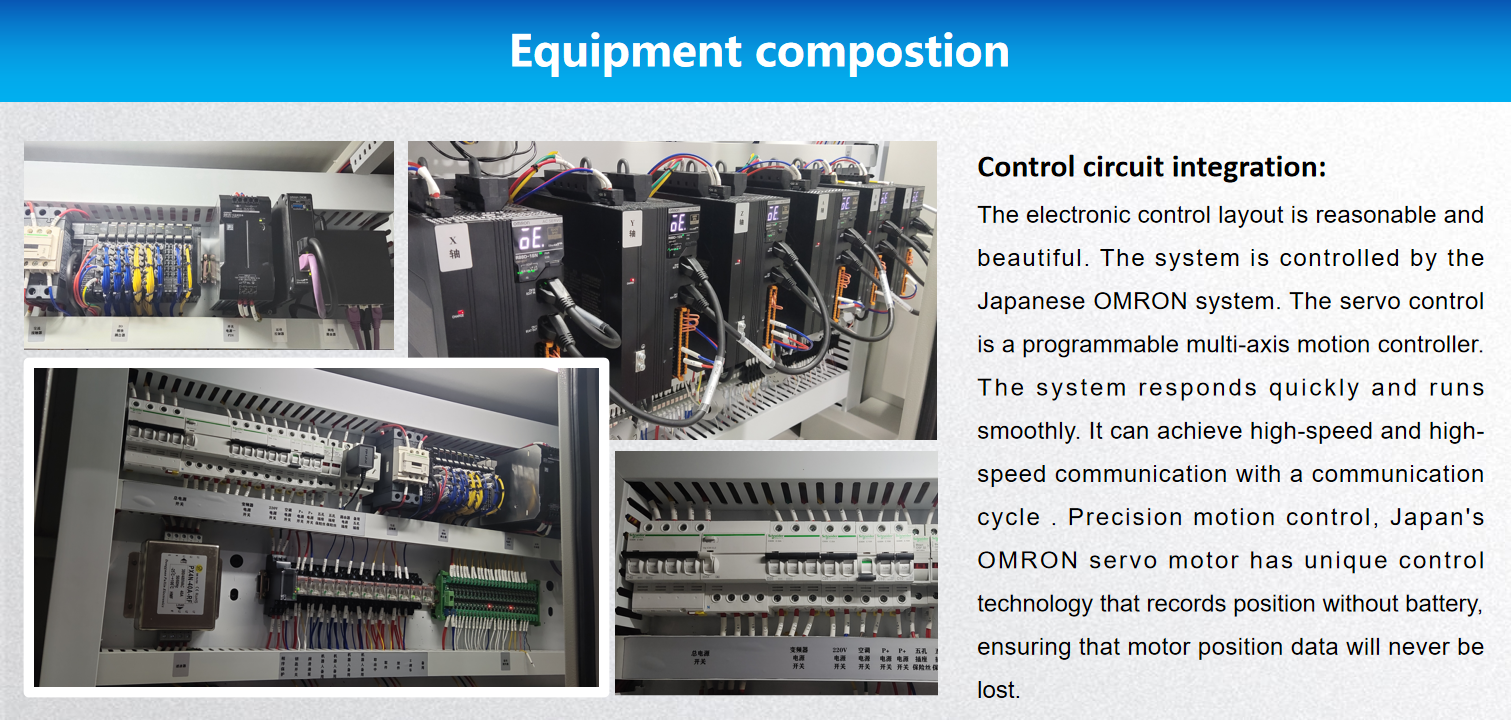

OMRON Control System: Features 6-axis linkage for complex 3D trajectories, with A/B/C rotary axes achieving ±110° (A-axis) and ±190° (B-axis) for multi-angle operations.

Dual Programming Modes: Combines CAM-generated G-code efficiency with tactile teaching pendant adjustments for hybrid workflows.

MES Integration:It can be upgraded remotely and in real time, and can interact with the MES system.

4.Energy-Efficient Operation

Power Management: Total driving power of 16.5kW with idle consumption reduced by 20%.

Dust Extraction: Closed-loop system recycles 35% of particulate waste, paired with optional water curtain filtration for hazardous materials.

Safety Compliance: IP54-rated enclosure with emergency stops and fire suppression protocols.

Robust Design for Mid - Scale Operations

Measuring 1700×2030×2500mm and with a platform load weight of 70kg, the LR - ZM6C - 65 Mid - Scale Deburring System is robustly built for mid - scale operations. Its sturdy construction ensures stability during heavy - duty deburring, while the 16.5kw total driving power supports continuous operation. The machine’s design fits well in standard factory floors, facilitating integration into existing production lines. By bringing deburring operations in - house for medium - sized parts, it reduces external processing costs and enhances quality control.

Diverse Industry Applications of the Mid - Scale Deburring System

Parameter

The LR - ZM6C - 65 Deburring Machine, a premier Mid - Scale Deburring System, is a testament to innovation for mid - scale manufacturing. It combines precision, flexibility, and efficiency, making it an ideal choice for businesses looking to enhance their medium - sized component production. Invest in this Mid - Scale Deburring System to experience improved productivity and uncompromised quality in your industrial operations.