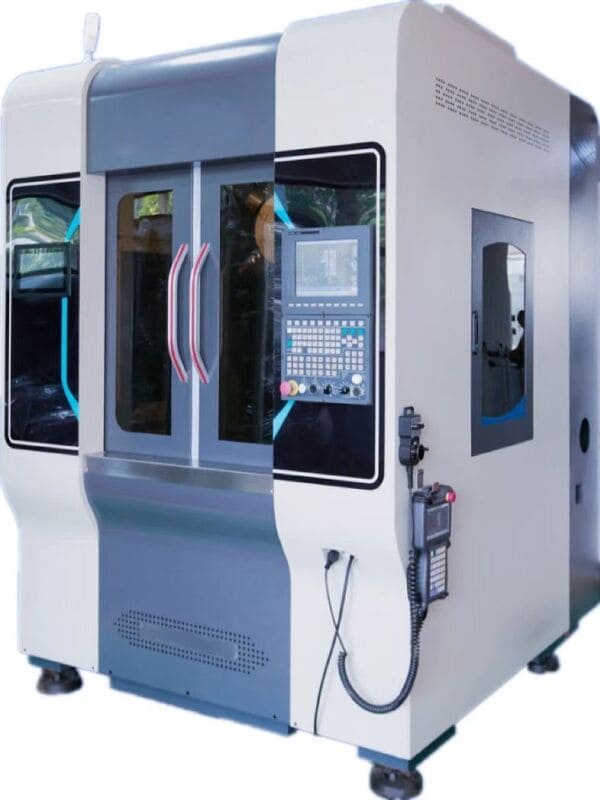

LR-ZM6B-35 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

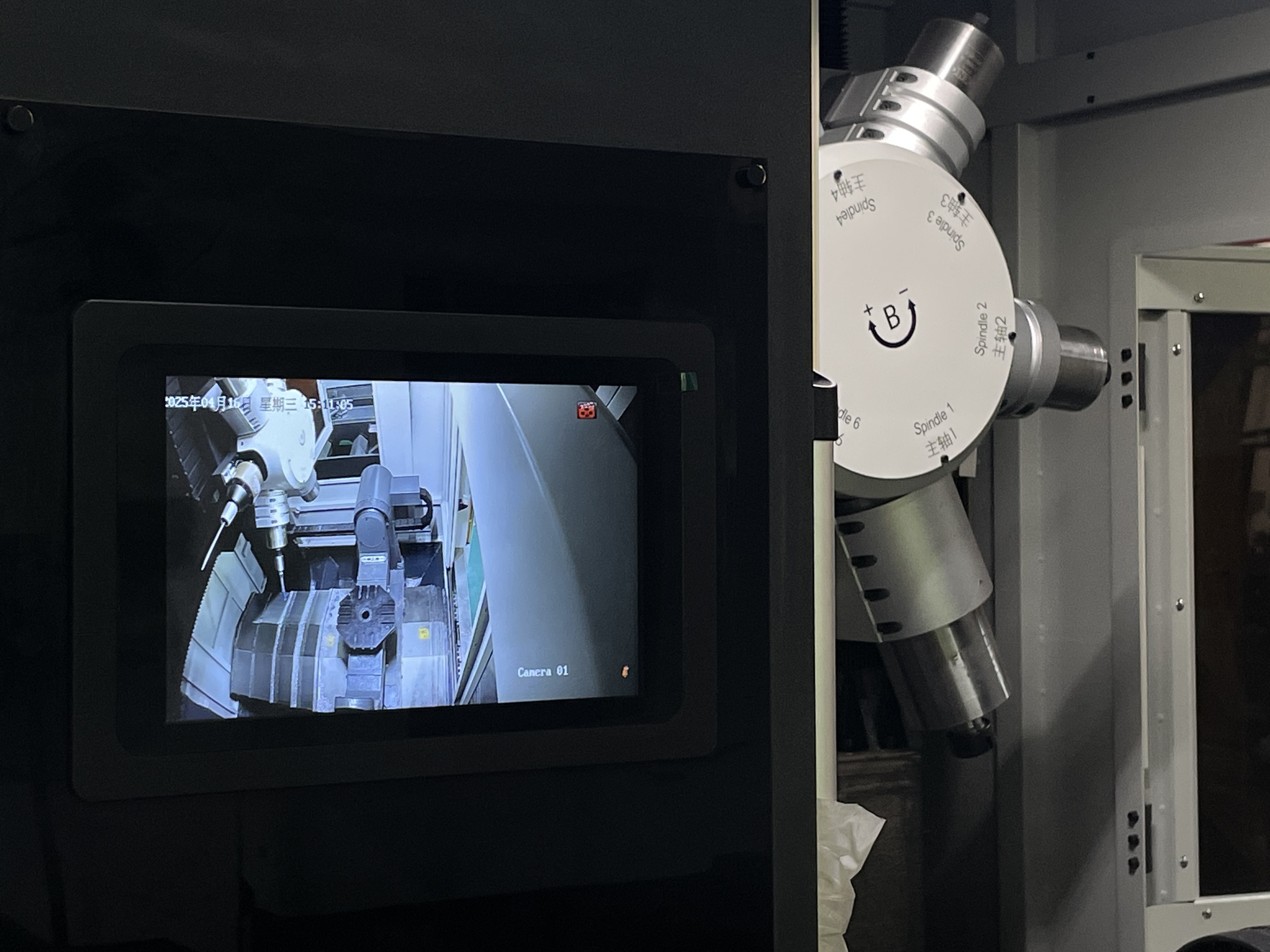

Equipped with SYNTEC’s multi-axis control and advanced thermal compensation, this system excels in processing automotive transmissions, aerospace brackets, and e-mobility components. Its modular tooling and MES integration streamline workflows, cutting cycle times.

The Compact Deburring Automation by DASEON redefines efficiency in small-scale die-casting post-processing. Traditional deburring solutions are lack the precision to handle intricate geometries, the agility for high-mix production, and the space efficiency for modern automated lines. Enter the LR-ZM6B-35 Compact Deburring Automation, a SYNTEC-powered solution designed to address these challenges with unmatched accuracy, flexibility, and compactness.

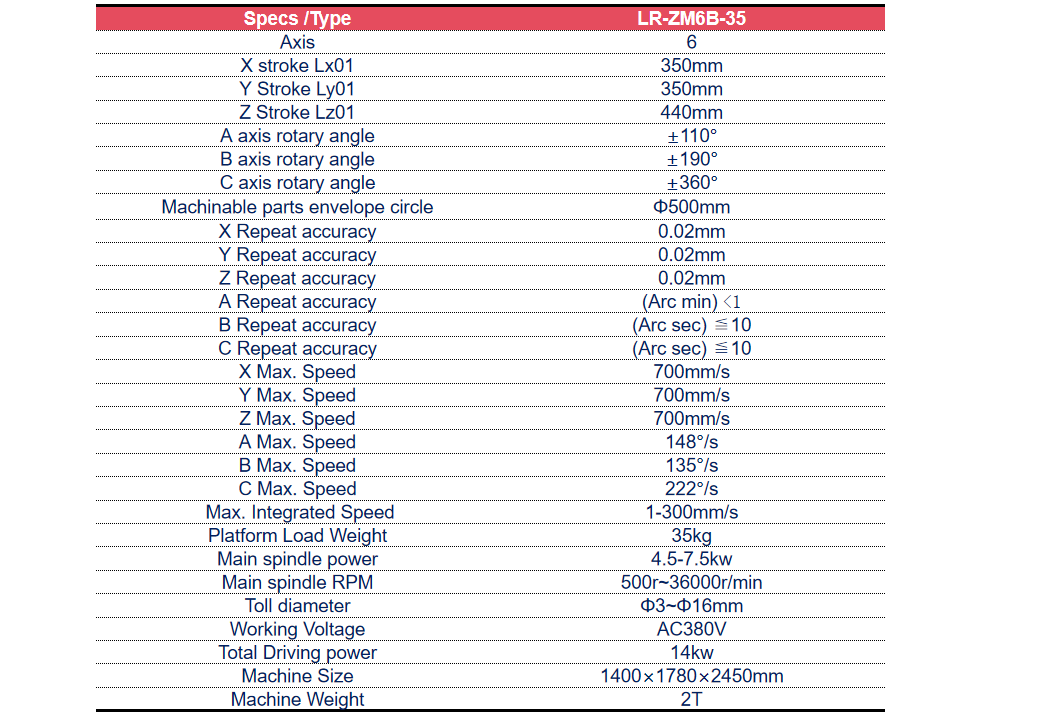

Compact Deburring Automation Core Technical Specifications

1.SYNTEC 6-Axis CNC System

--Axis Configuration: X/Y/Z linear axes (350mm/350mm/440mm strokes) + A/B/C rotary axes (±120°/±190°/±360°).

--Max. Speed: 700mm/s (linear axes), 222°/s (C-axis).

--Spindle Power: 4.5–7.5W, 500–36,000 RPM.

--Repeat Accuracy: ≤0.02mm (X/Y/Z), ≤10 arc seconds (B/C axes).

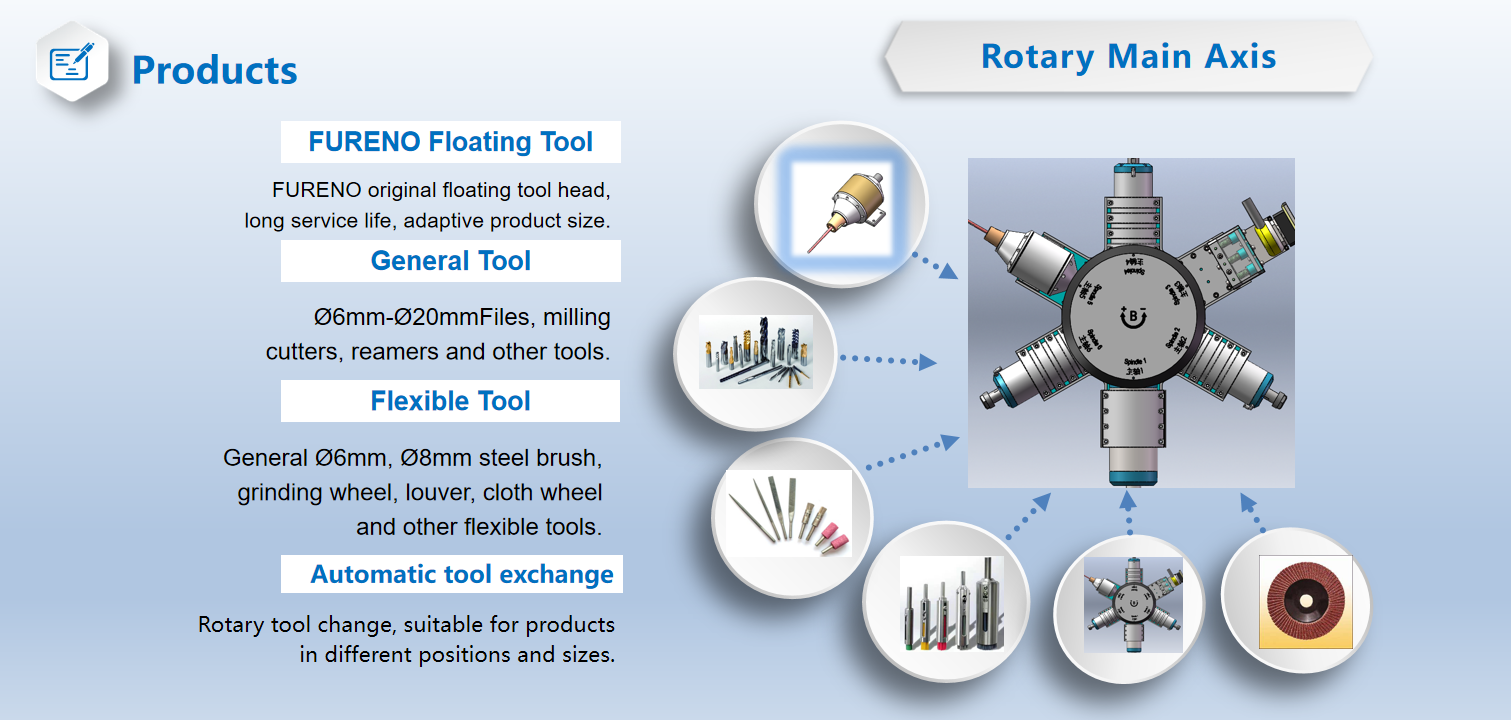

2.Automated Tool Management

--6-Station Rotary Tool Changer: Supports rigid tools (milling cutters, reamers) and flexible tools (steel brushes, grinding wheels) for hybrid workflows.

--Automatic Tool Compensation: Laser-based calibration adjusts tool wear in real time, extending tool lifespan (e.g., 2,000 cycles for carbide mills).

--Tool Breakage Detection: Halts operations within 0.1s to prevent defective batches.

3.Workholding & Safety

--Quick-Change Fixtures: Utilizes 1:2 locating pins and pneumatic couplings for 15-minute fixture swaps.

--IP54 Enclosure: Fully enclosed structure with safety light curtains and emergency stop protocols.

Compact Deburring Automation Industry-Specific Applications

1.Medical Device Manufacturing

--Titanium Implants: Deburrs orthopedic screws with ≤0.02mm dimensional tolerance.

--Surgical Instruments: Cleans Ø2mm lumens in stainless steel tools, eliminating contamination risks.

2.Automotive Microcomponents

--ADAS Sensor Housings: Ensures leak-proof seals for Ø5mm ports.

--Connector Terminals: Polishes brass contacts, reducing electrical resistance.

Compact Deburring Automation Operational Excellence: Productivity Redefined

1. Programming Efficiency

3D CAD Integration: Directly import STEP files to generate toolpaths, reducing setup time substantially compared to manual coding.

Manual Teaching Mode: Real-time trajectory adjustment for prototype iterations, cutting trial-and-error time by 50%.

2. Maintenance & Safety

Thermal Stability: Cast iron structure with built-in temperature sensors maintains thermal control, critical for long-running precision tasks.

Dust Management: Optional HEPA filtration (Class 100 compatibility) ensures cleanroom compliance, vital for medical and semiconductor applications.

Parameter

The Mid-Scale Deburring System by DASEON bridges the gap between agility and capacity, offering manufacturers a scalable solution for medium-volume, high-mix production.