CG Series Hot Chamber Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

Engineered specifically for hot chamber die casting equipment, the CG Series delivers unmatched precision for zinc alloy components.

With ≥6m/s injection speed and patented dual-fuel furnace technology, CG Series Hot Chamber Die Casting Machine ensure consistent results across 88-400-ton clamping force, setting new standards for sanitaryware, electronics, and automotive industries.

Core Features

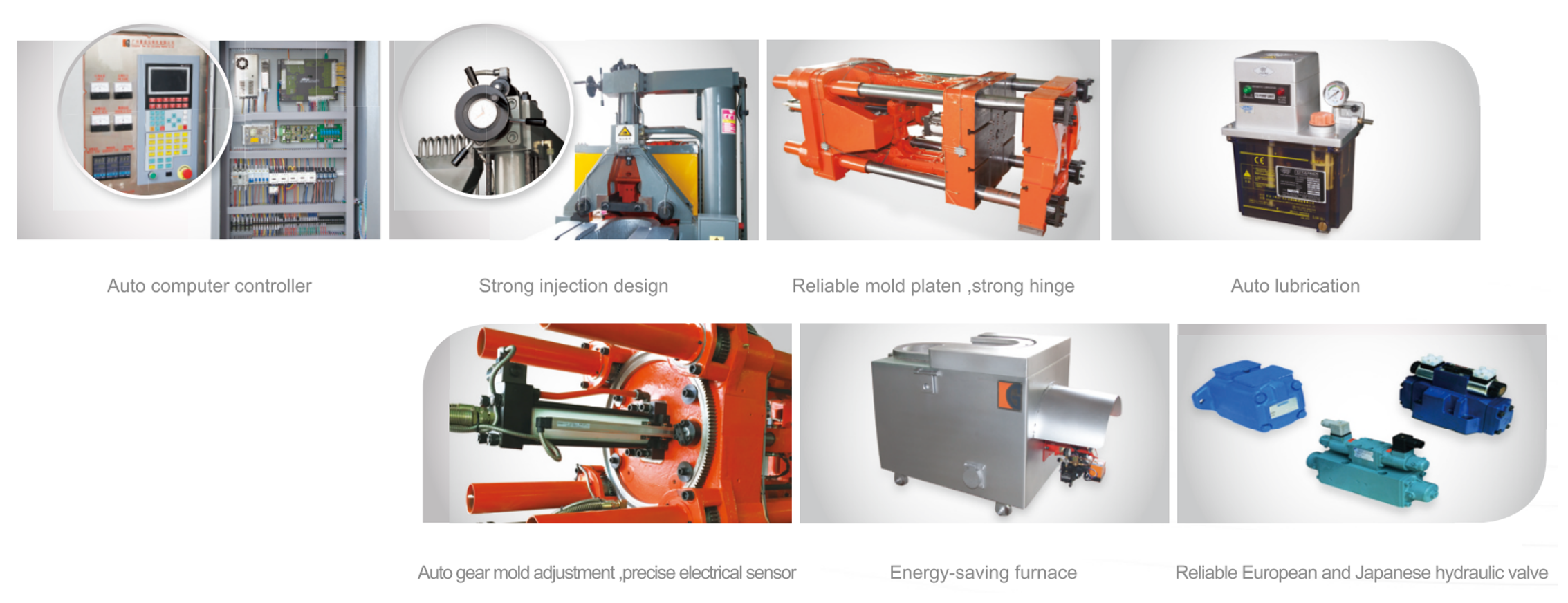

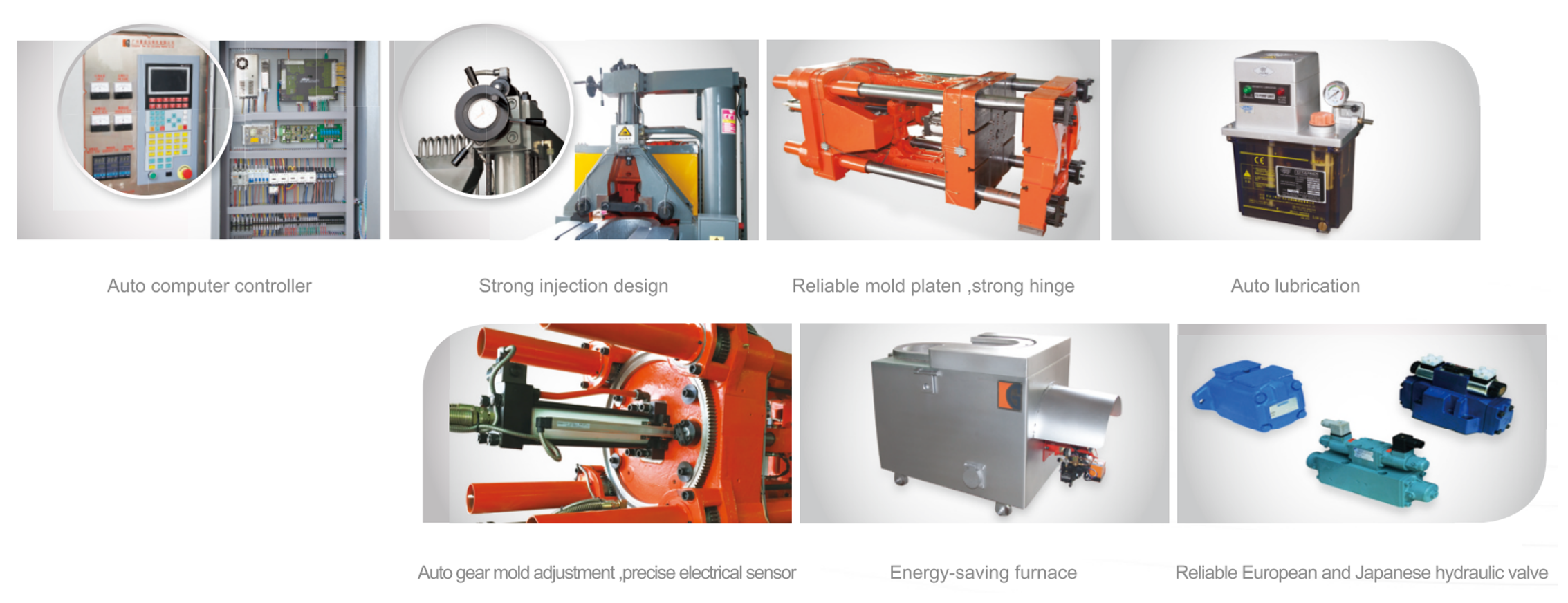

1. Standard Configuration

| System | Technical Specifications | Advantages for Hot Chamber Casting |

Control System | MIH-6117 CNC, 10.1" touchscreen, 200-mold parameter storage | Real-time diagnostics critical for hot chamber die casting equipment |

Hydraulic System | Proportional valves (Yuken), oil temperature control (±2℃ fluctuation) | ±1% flow accuracy for ultra-thin wall (<0.5mm) hot chamber casting |

Clamping System | Reinforced beam structure with low-pressure protection (<=5MPa) | ≤0.03mm template deformation for mold longevity in hot chamber die casting |

Furnace System | Dual-fuel energy-saving furnace (350kg diesel/300kg electric) | 15-minute fuel switching for flexible hot chamber die casting operations |

2. Optional Upgrades

| Module | Technical Specifications | Enhancements for Hot Chamber Casting |

Automation | Servo spray-pick robot (

- 1.5m/s speed, 0-200ml spray volume, ±0.05mm repeatability | Faster cycle time and better surface quality for hot chamber die casting |

Process Optimization | Particle lubrication system (

- Φ50-Φ90mm plunger compatibility, ±0.5g dosing accuracy | Longer plunger lifespan and lubricant savings in hot chamber die casting |

Furnace Upgrade | Imported gas burner (200kW max heat load), 316L stainless steel water jacket | Combustion efficiency improvement for eco-friendly hot chamber die casting equipment |

Advanced Technology Deep Dive

Dual-Fuel Furnace Innovation:

The CG Series incorporates a patented hot chamber die casting equipment furnace design that reduces CO₂ emissions by 25% while maintaining 85% thermal efficiency. This technology allows seamless switching between diesel and natural gas, adapting to regional energy availability.

Proportional Hydraulic Control:

By integrating Japanese Yuken proportional valves, the CG Series achieves injection speed control within ±0.1m/s. This precision is critical for producing intricate parts like bathroom fixtures with wall thickness down to 0.5mm.

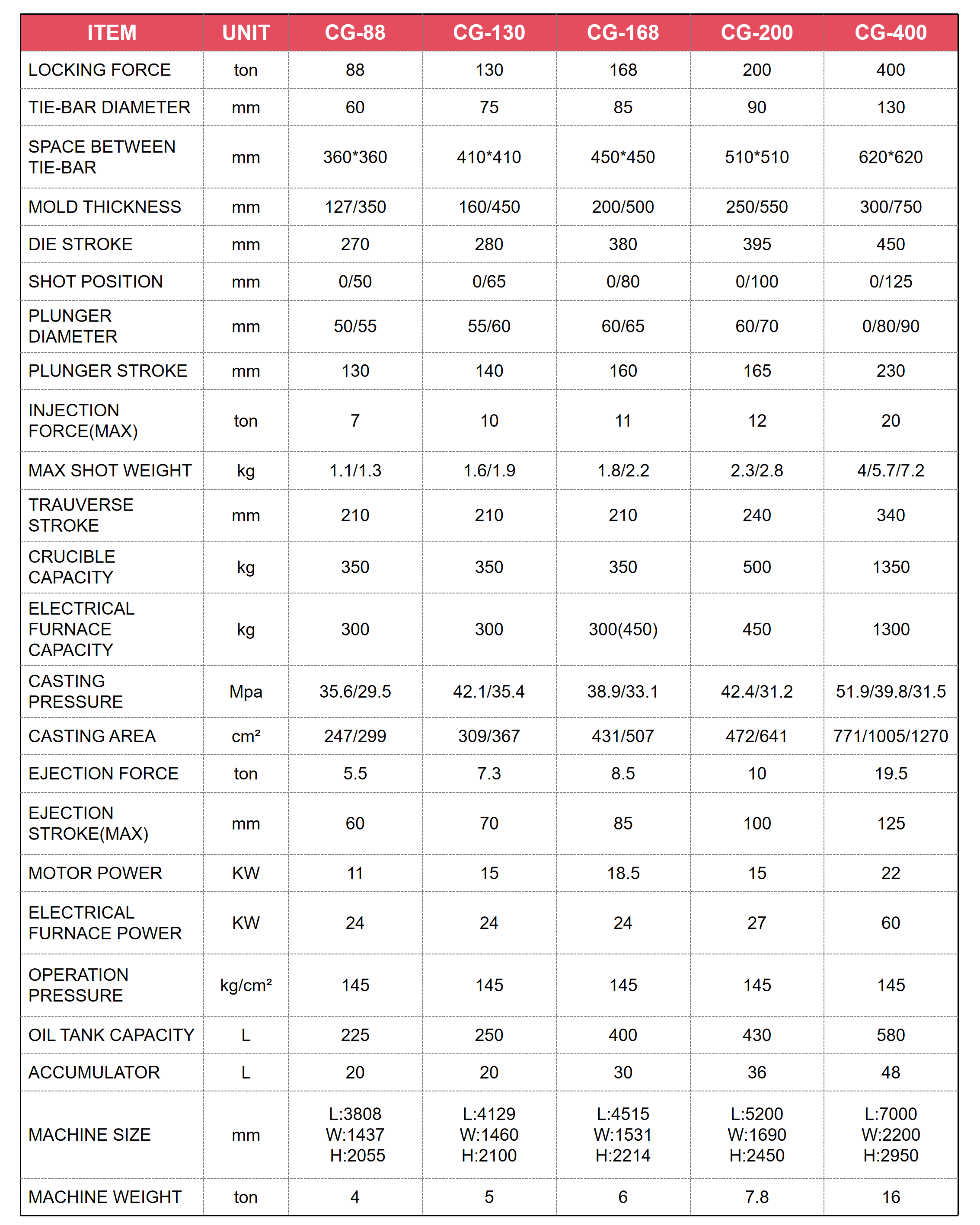

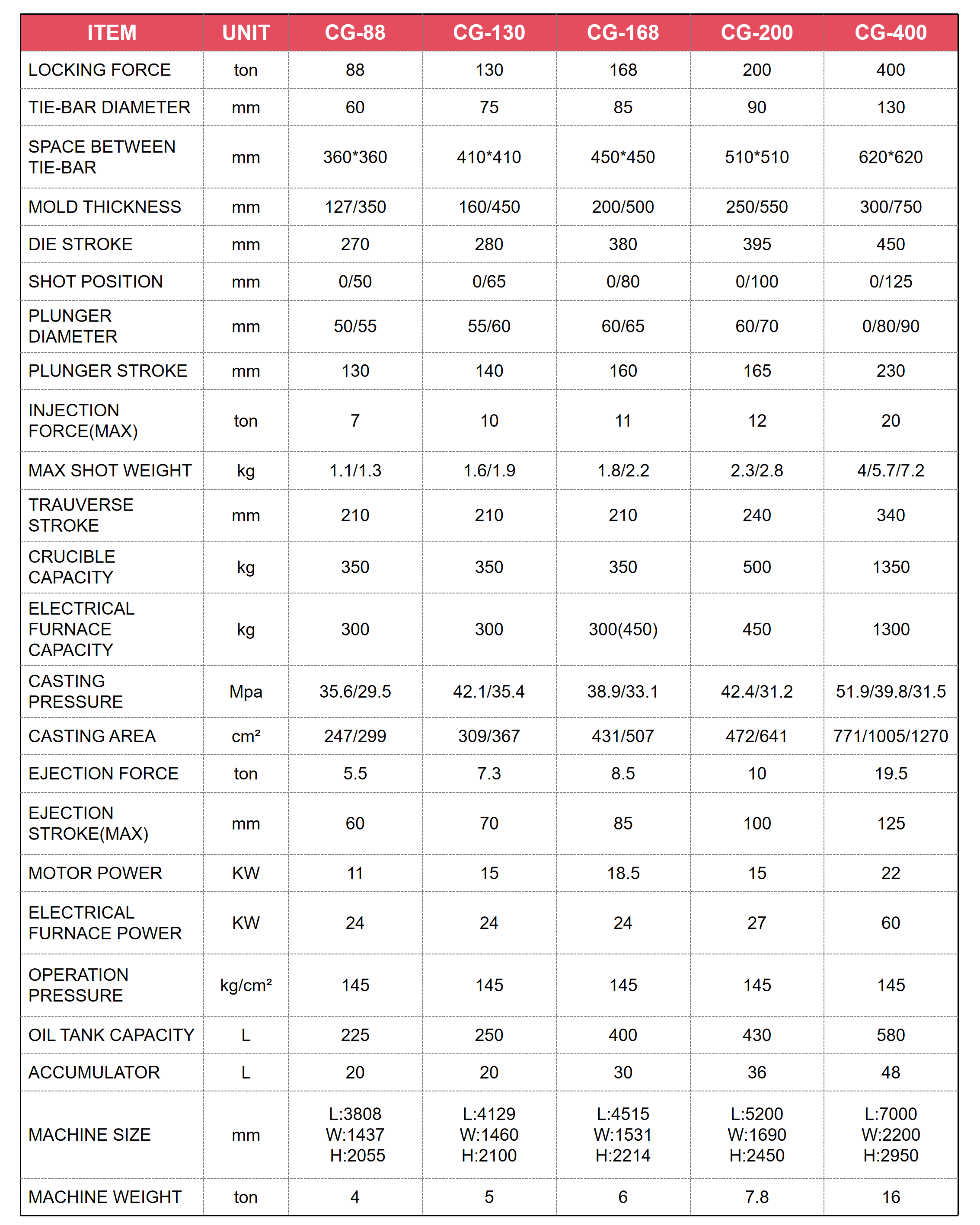

Parameter

Conclusion

The CG Series represents the future of hot chamber die casting equipment, offering:

High-Speed Precision: ≥6m/s injection speed and ±0.05mm robot repeatability.

Energy Efficiency: 40% lower fuel costs through dual-fuel furnace technology.

Process Flexibility: Adaptable to small components (0.5mm) and large molds (620x620mm).

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.