20Ton Class Hydraulic Trim Press Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

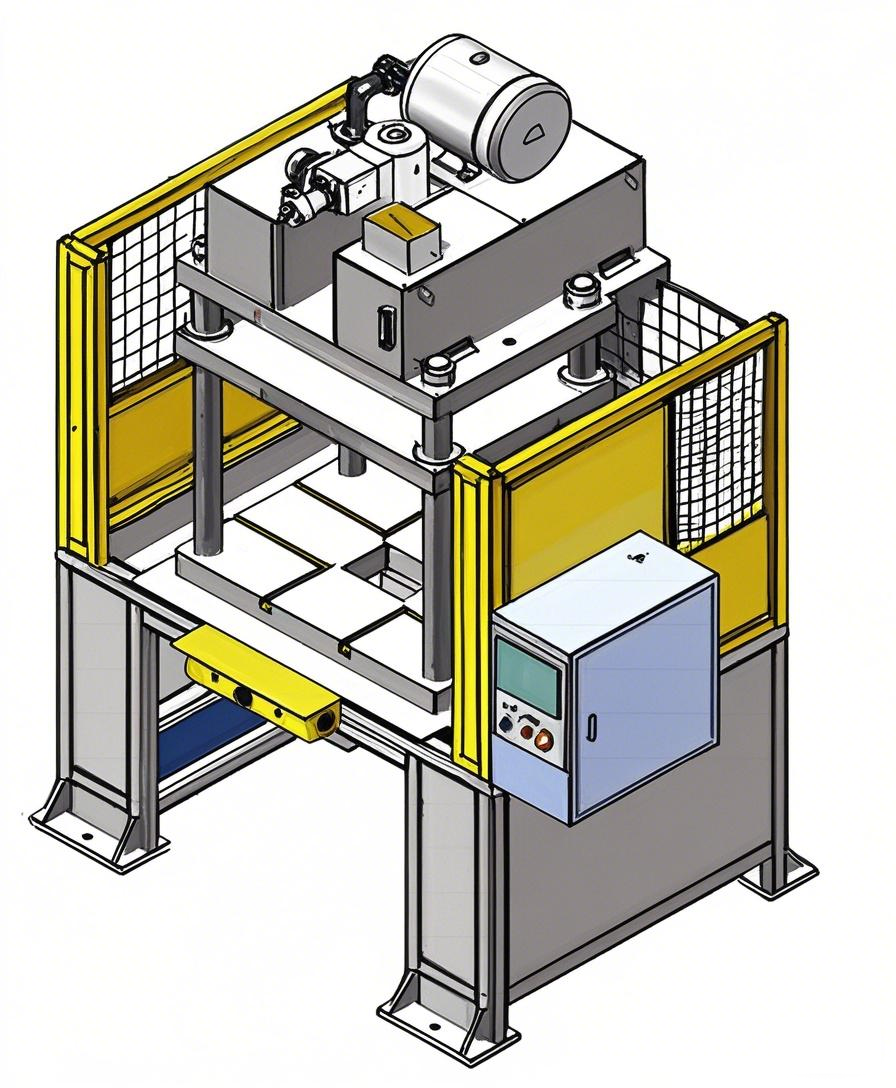

The 20Ton hydraulic trimming press machine is a compact, precision-engineered solution for small-scale manufacturing requiring high accuracy and energy efficiency.

Utilizing advanced hydraulic transmission, it delivers stable 200KN force via a 8.5KW three-phase power system, balancing performance with low power consumption. Its four-post three-plate structure, paired with precision-guided bushings, ensures ≤0.05mm parallelism between platens and ≤0.02mm/m verticality error, critical for micron-level precision in delicate operations.

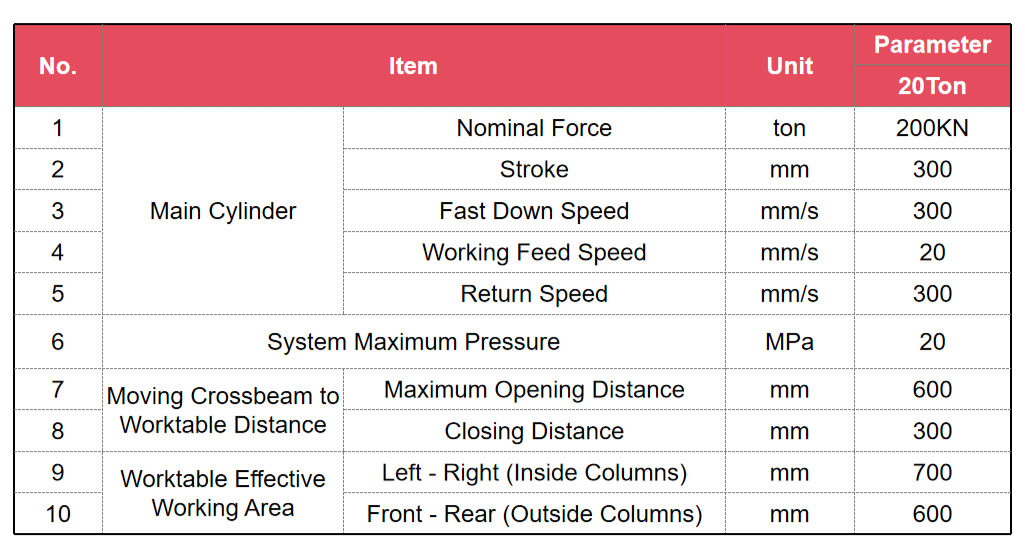

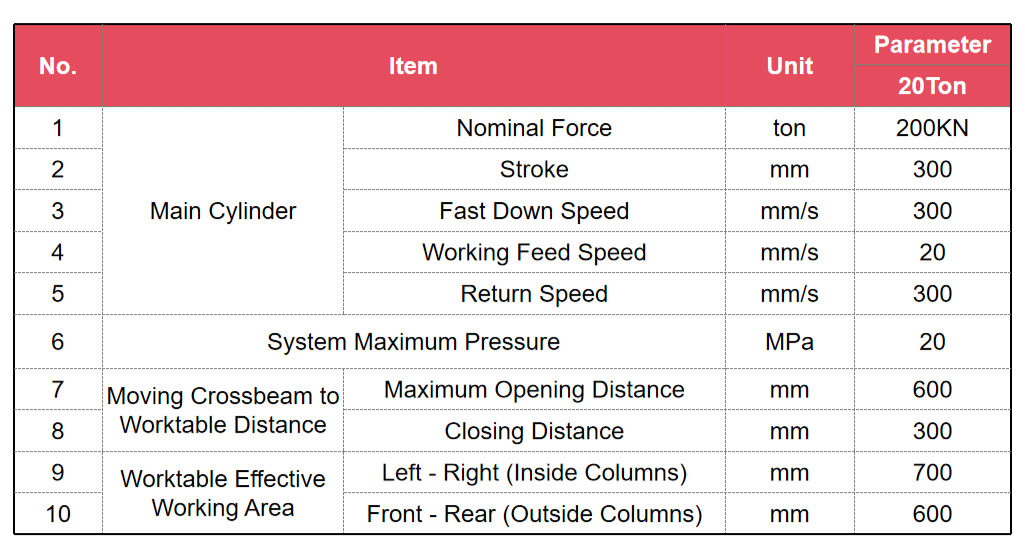

| Parameter | Value | Operational Impact |

|---|

| Nominal Force | 200KN (20T) | Optimal for trimming thin plastics, embossing lightweight sheets, and small-component molding. |

| Stroke | 300mm | Balances mold space and processing depth for small-to-medium workpiece heights. |

| Speed | Rapid: 300mm/s

Working: 20mm/s | Reduces idle time with fast approach/return; controlled feed ensures precision during material contact. |

| System Pressure | 20MPa | Consistent power delivery for repeatable forming, even in extended production runs. |

| Power Consumption | 8.5KW (max) | Energy-efficient design suitable for cost-sensitive operations. |

The hydraulic trimming press excels in producing micro-components for consumer electronicsThe press’s stable pressure control prevents deformation in fragile materials like polyimide, achieving ±0.05mm dimensional accuracy—critical for automotive electronics where component reliability is paramount. Semi-automatic mode boosts throughput for batch production of connector parts, while manual mode allows prototyping of custom geometries.

For high-volume production of small plastic parts, the hydraulic trimming press provides both speed and precision.Adjustable dwell time (0–24 hours) accommodates varied plastic curing needs: 1–3 hours for ABS to ensure complete mold filling, or 6–8 hours for PC to eliminate stress cracking. The press’s low-vibration operation protects intricate molds, extending tool life by 20% compared to mechanical alternatives.

In the production of miniature mechanical parts, the hydraulic trimming press offers unmatched repeatability.Suited for trimming ceramic substrates, manufacturing miniature gearboxes, and forming sensor housings for medical devices. Essential for aerospace components where dimensional consistency directly impacts assembly performance. The compact footprint (1.5m x 1.2m) fits the tight spaces of cleanroom environments.

Robust Mechanical Design

The four-post architecture distributes load evenly, minimizing frame deflection under pressure. This design reduces tool wear, making it suitable for long-term use with hard materials like fiber-reinforced plastics.

User-Centric Controls

A PLC-based HMI interface allows intuitive adjustment of speed, pressure, and dwell time. Operators can switch between manual (for trial runs) and semi-automatic (for mass production) modes, with safety interlocks that pause operation when the guard is opened. Real-time cycle counting and fault diagnostics (e.g., low oil pressure alerts) streamline production management and reduce downtime.

Low Maintenance Requirements

Routine upkeep for the hydraulic trimming press is streamlined.The modular pump unit enables quick servicing without major disassembly, while a regenerative circuit recovers energy during the return stroke, cutting power usage compared to non-regenerative models.

Smooth Force Transmission

Unlike pneumatic systems prone to pressure fluctuations, the hydraulic design provides continuous, shock-free force—critical for processes where sudden pressure changes could damage workpieces. This stability is especially valuable in trimming delicate materials like OLED display films, where edge quality directly affects product yield.

Precision Pressure Regulation

A proportional pressure valve allows 0.1MPa increments, enabling fine-tuning for applications ranging from gentle embossing to firm forming. For example, trimming 0.5mm-thick PVC sheets uses 12MPa to avoid melting, while forming 1mm ABS requires 18MPa to ensure crisp edges—all adjustable via the control panel in seconds.

Parameter

The 105-20T hydraulic trimming press bridges precision, versatility, and cost-effectiveness, catering to industries where small-scale, high-accuracy processing is essential. Its robust design, intuitive controls, and energy-efficient operation make it a strategic investment for manufacturers seeking to optimize quality and productivity without compromising on operational simplicity.

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.