300Ton Class Hydraulic Trim Press Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

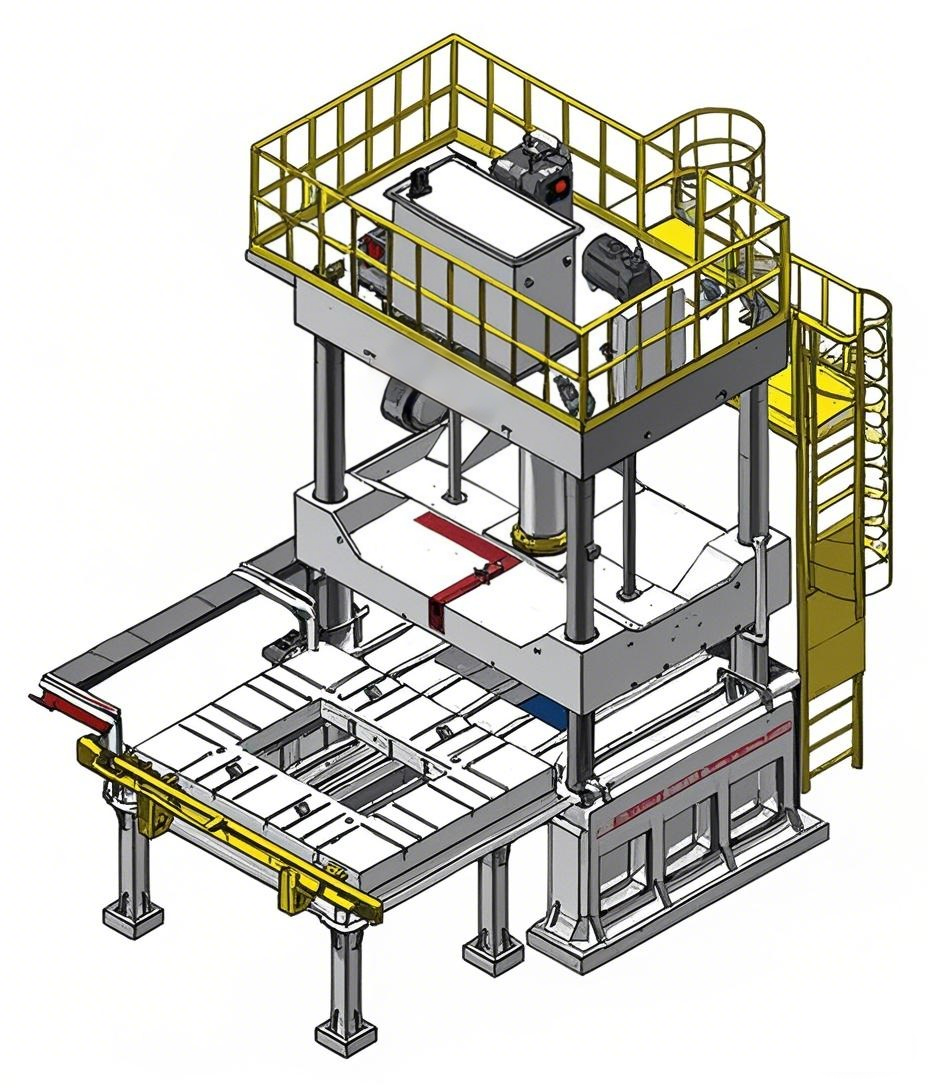

The 300-Ton hydraulic forming press stands as a pinnacle of engineering innovation, built to deliver 3000KN of controlled force for ultra-heavy material processing.

Tailored for industries demanding precision in aerospace, energy, heavy machinery, and large-scale tooling, this hydraulic forming press excels in deep drawing, high-pressure molding, and intricate forming of thick-gauge metals, advanced composites, and engineering plastics. Combining robust hydraulic power, expansive working capacity, and intelligent controls, it redefines what's possible in heavy-duty industrial manufacturing.

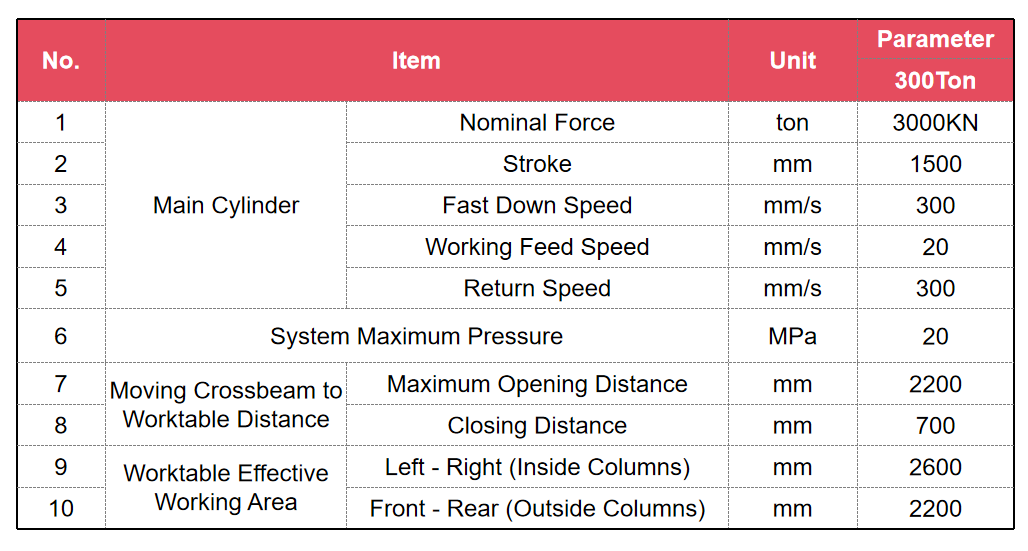

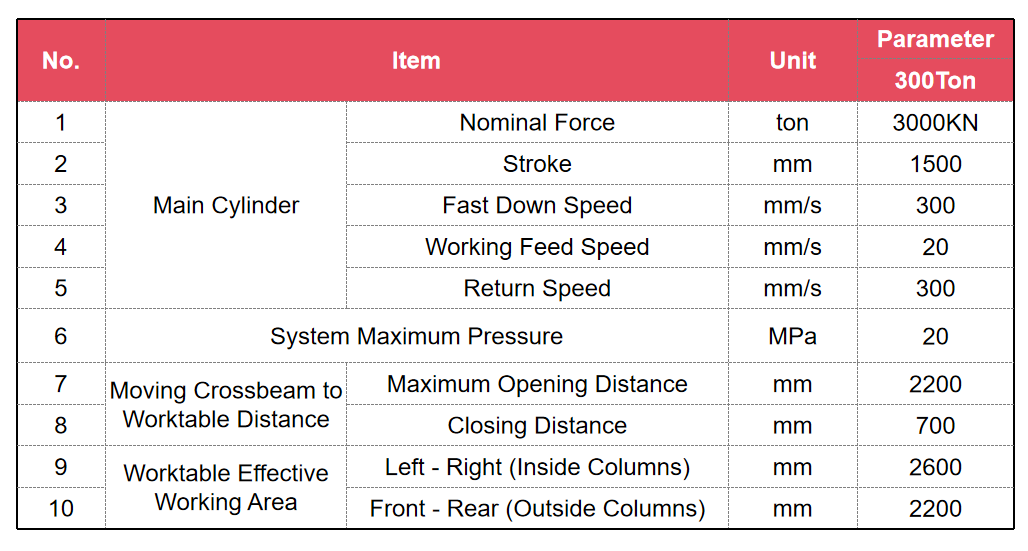

Nominal Force: 3000KN (300 metric tons), optimized to handle 15–30mm steel plates, 10–20mm fiber-reinforced composites, and other dense materials with uniform force application across the entire operational range.

Stroke Capability: 2000mm stroke length enables deep forming up to 1000mm, accommodating complex 3D geometries and tall molds essential for aerospace and energy sector components.

Work Surface Dimensions: 2500x2000mm (LxW) provides an expansive platform for multi-cavity tooling or oversized workpieces, enhancing productivity in high-volume production environments.

Adjustable System Pressure: 30MPa maximum pressure (0.5MPa incremental adjustment) with ±0.1% stability via a precision proportional valve, ensuring consistent material deformation in high-strength applications.

Vertical Clearance: 2500mm maximum open height facilitates easy installation of large molds and high-clearance workpiece handling in heavy industrial setups.

Power and Speed Parameters: 75KW three-phase motor supports rapid approach/return at 200mm/s and adjustable working feed speeds (2–10mm/s) for controlled material engagement, minimizing risks of cracking in thick materials.

Programmable Dwell Function: 0–48 hours of adjustable dwell time supports extended processes such as composite resin curing, stress relief in metal forming, and dimensional stabilization for large components.

The 300-Ton hydraulic forming press (105-300T) represents the forefront of heavy-duty industrial forming technology, combining unparalleled force, precision, and versatility. Designed for the most demanding applications in aerospace, energy, and heavy machinery, it empowers manufacturers to process ultra-thick materials and large components with exceptional accuracy and efficiency. With its robust design, intelligent controls, and industry-leading compliance, this hydraulic forming press is an indispensable asset for any operation requiring reliable performance in heavy industrial manufacturing.

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.