50Ton Class Hydraulic Trim Press Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

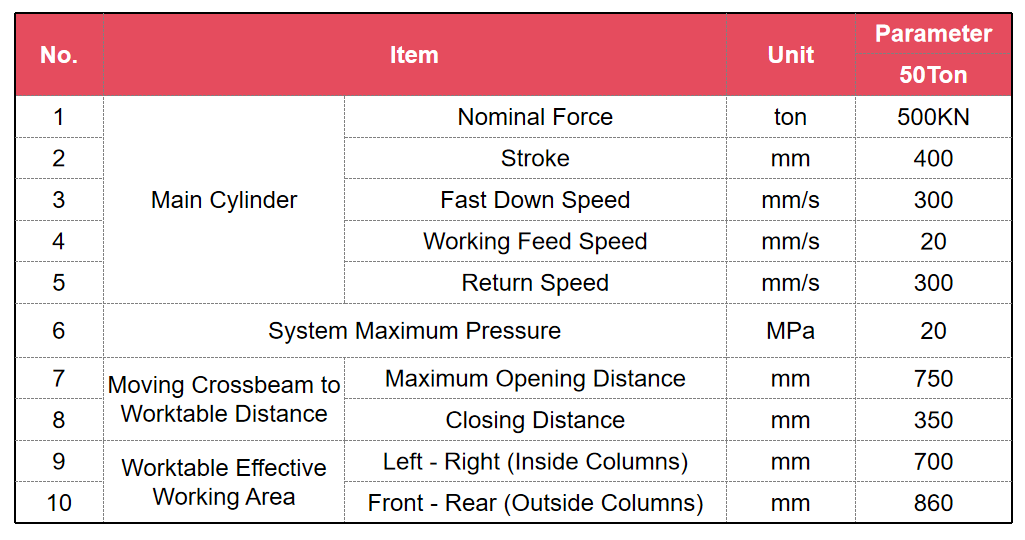

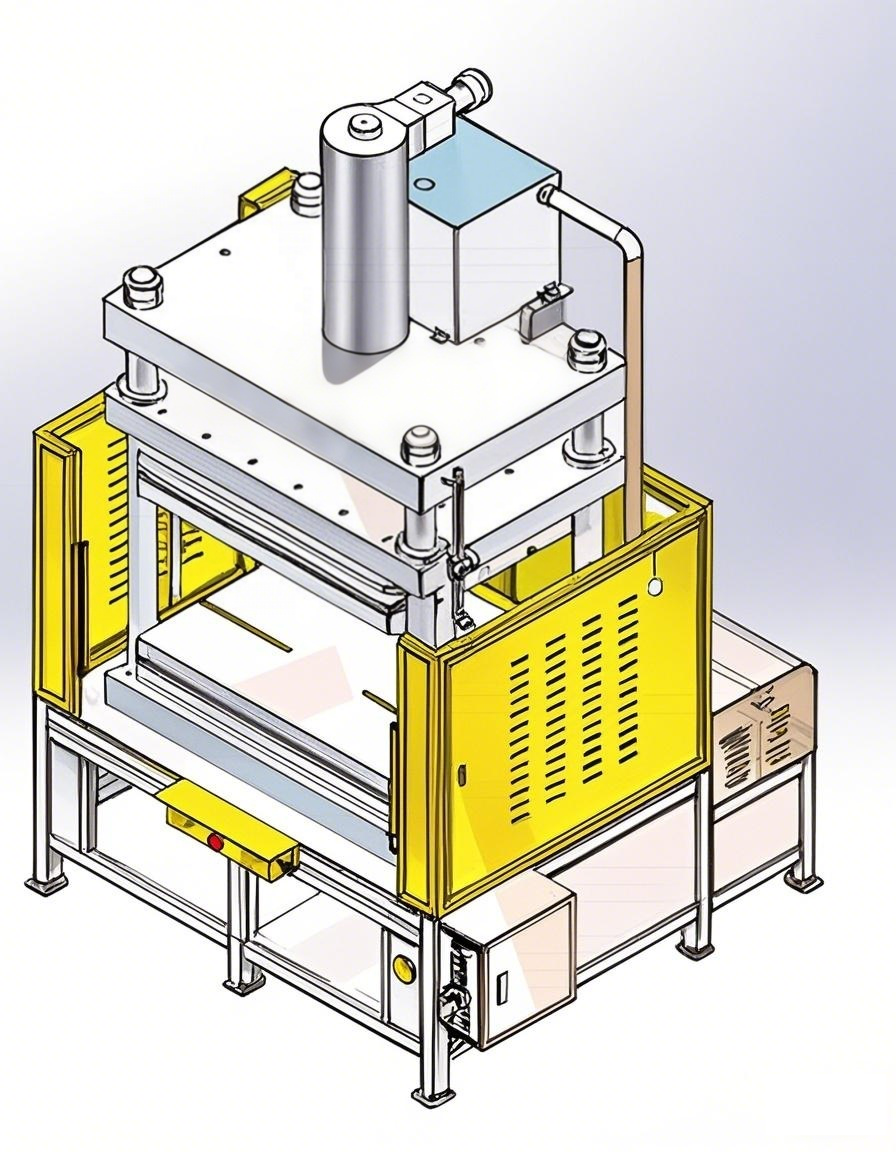

The 50Ton hydraulic forming press (model 105-50T) is a versatile industrial solution designed to deliver 500KN of controlled force, balancing robust power with meticulous precision for medium-thickness material processing.

Ideal for industries ranging from automotive components to consumer goods manufacturing, this hydraulic forming press excels in tasks like deep drawing, embossing, and precision trimming, where consistent force and positional accuracy are critical. Its advanced hydraulic transmission system, paired with a rigid four-post three-plate structure, ensures stable performance across diverse materials, including 2–5mm plastic sheets, 1–3mm metal plates, and composite materials.

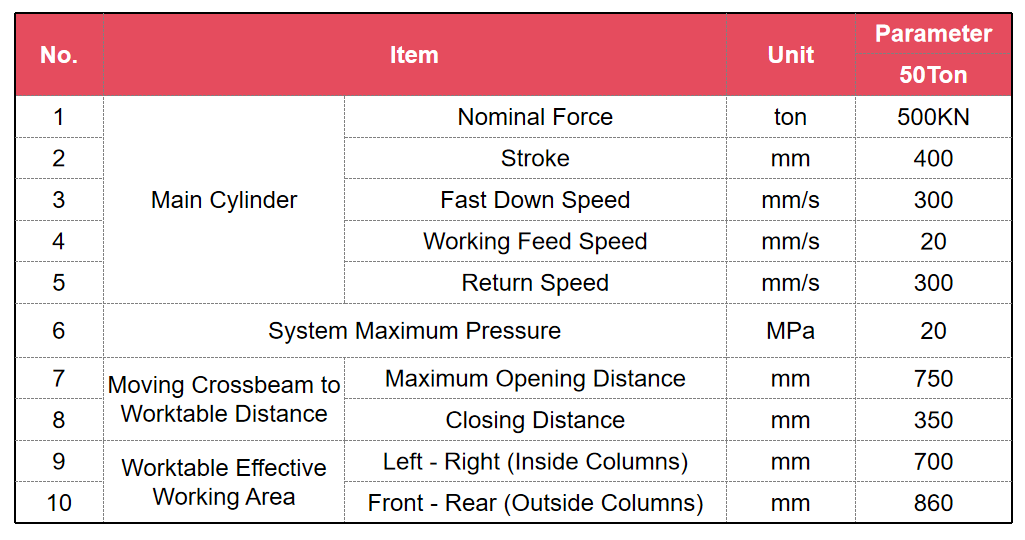

Nominal Force: 500KN (50 metric tons), optimized for medium-depth forming operations that require both strength and finesse.

Stroke Length: 400mm, enabling deep drawing up to 200mm—perfect for taller molds or complex geometric shapes in automotive interiors or appliance components.

Working Surface: 1000x800mm, providing ample space for multi-cavity tooling or large workpiece processing, enhancing efficiency in batch production.

System Pressure: 20MPa (constant), maintained via a proportional pressure valve to ensure stability even during extended operation.

Speed & Power: 15KW motor with rapid approach/return at 300mm/s to minimize idle time; adjustable working feed speed (5–20mm/s) for controlled material engagement, preventing defects like stretch marks or burrs.

Dwell Time: 0–24 hours programmable, supporting applications from thermoset plastic curing to stress relief in metal forming, ensuring complete material deformation and dimensional stability.

The hydraulic forming press is a cornerstone in producing mid-sized automotive parts

For manufacturing durable and precise appliance components, the hydraulic forming press shines:

Carbon Fiber Trimming: Processes 3mm-thick carbon fiber composite sheets for bicycle handlebars, utilizing the hydraulic forming press’s low-vibration hydraulic system to prevent fiber delamination—a frequent problem with pneumatic or mechanical alternatives.

Pharmaceutical Blister Packaging: Forms 0.8mm PVC blisters with optional mold temperature control (±2°C), ensuring consistent material stretch and seal integrity for medical-grade packaging that meets strict regulatory standards.

Four-Post Three-Plate Structure: Distributes load evenly across the frame, minimizing deflection and maintaining platen parallelism within 0.05mm. The platens resist wear over 200,000+ cycles, making the press a reliable workhorse for high-volume production.

Precision-Guided Bushings: Four sintered-metal bushings guide the moving platen, ensuring a verticality error,It is essential for deep drawing operations where misalignment can ruin entire batches of parts.

PLC-Based HMI Interface: A user-friendly touchscreen allows operators to program force, speed, and dwell time with ease. Storing up to multiple custom recipes, it reduces setup time when switching between materials like plastic, aluminum, or steel.

Dual Operation Modes: Manual mode for prototyping and fine-tuning, and semi-automatic mode for high-speed batch production , with safety interlocks to protect operators during use.

Hydraulic System Care: High-efficiency return-line filter traps particles and reducing unexpected downtime.

Regenerative Energy Circuit: Eco-friendly feature that aligns with global sustainability goals.

Unwavering Force Stability: Unlike mechanical presses that lose torque at deeper strokes, the hydraulic forming press maintains full 500KN nominal force throughout the entire working range, ensuring uniform material deformation from start to finish.

Adaptive Pressure Control: Adjust pressure in 0.5MPa increments to handle delicate materials like soft PVC and robust metals like aluminum on the same machine, eliminating the need for multiple presses and reducing capital expenditure.

Quick Mold Changeovers: A motorized height-adjustable table (0–100mm range) enables fast tooling swaps without manual reconfiguration, making the press ideal for mixed-production environments that require frequent material or mold changes.

The 50Ton hydraulic forming press (105-50T) is a testament to engineering excellence, combining 500KN of reliable force with precision controls and durable design. It empowers manufacturers to tackle diverse medium-load tasks—from automotive component forming to medical packaging—with unmatched consistency and efficiency. By prioritizing user-friendly operation, low maintenance, and energy efficiency, this hydraulic forming press sets a new standard for versatility in industrial processing, making it an indispensable asset for modern manufacturing environments.

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.