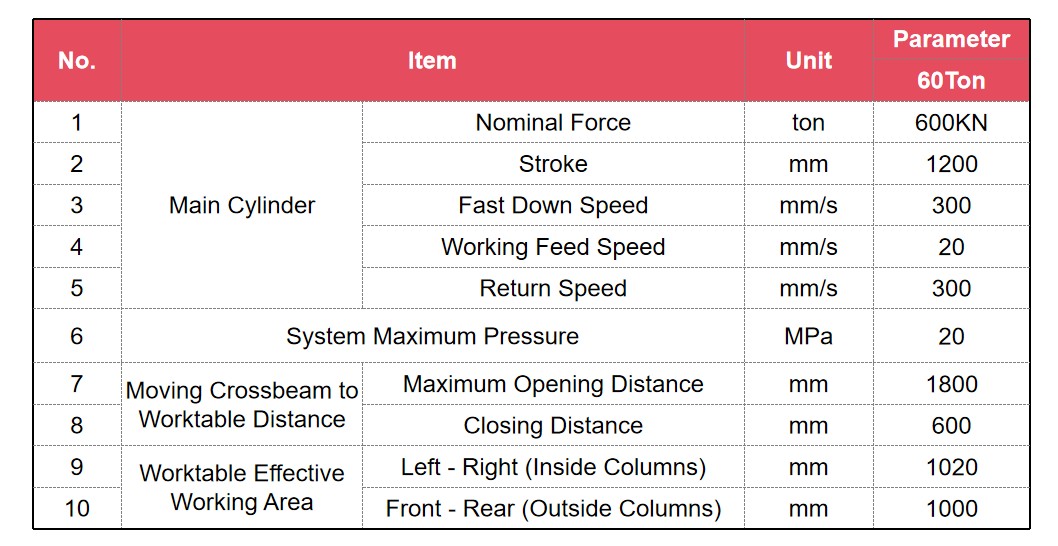

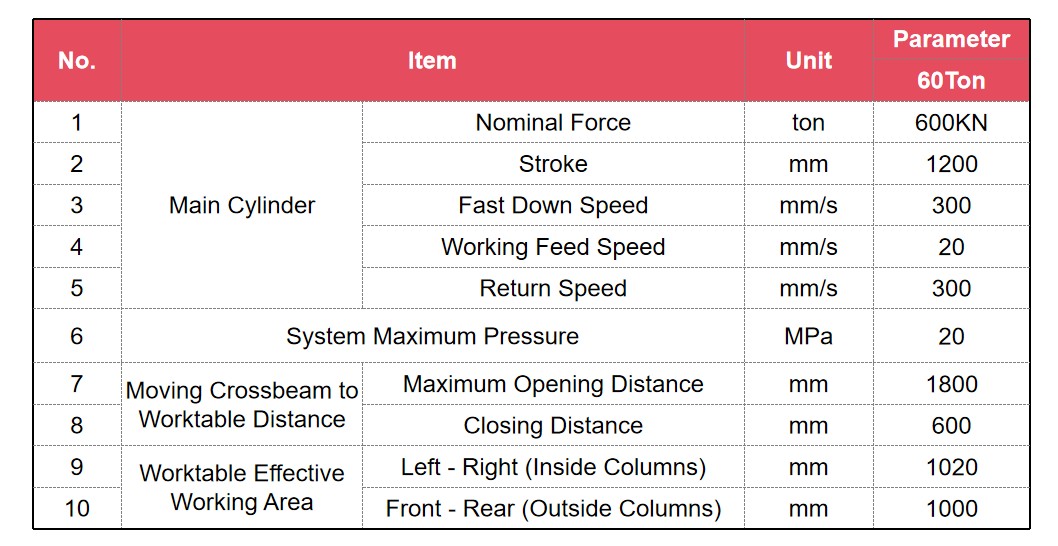

60Ton Class Hydraulic Trim Press Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The 60Ton hydraulic forming press is a high-performance machine designed to deliver 600KN of controlled force, blending robust power with meticulous precision for medium-to-heavy material processing.

As a versatile hydraulic forming press, it excels in deep drawing, precision trimming, and complex component manufacturing, catering to industries such as automotive, industrial equipment, and composites. Capable of handling 3–8mm plastic sheets, 2–5mm metal plates, and fiber-reinforced materials, this press combines a large working envelope with advanced hydraulic technology to meet the demands of modern industrial production.

Nominal Force: 600KN (60 metric tons), optimized for mid-heavy applications where consistent force is critical for material deformation without over-engineering.

Stroke Length: 1200mm, enabling deep forming up to 600mm to accommodate tall molds and complex 3D geometries, a key advantage of this hydraulic forming press.

Working Surface: 1020x1000mm (LxW), providing ample space for multi-cavity tooling or oversized workpieces to enhance batch production efficiency.

System Pressure: 20MPa (adjustable in 0.5MPa increments), maintained with ±0.3% stability via a proportional pressure valve, ensuring uniform material processing across all cycles.

Max. Open Height: 1800mm, facilitating easy installation of tall molds and high-clearance workpiece handling, a feature that distinguishes this hydraulic forming press in its class.

Power & Speed: 18.5KW three-phase motor with rapid approach/return at 300mm/s and adjustable working feed speed (5–30mm/s) for controlled material engagement.

Dwell Time: 0–24 hours programmable, supporting applications like thermoset curing, stress relief, and dimensional stabilization in molded parts.

The hydraulic forming press is pivotal in producing critical mid-sized components:

For heavy-duty machinery components, this hydraulic forming press delivers unmatched performance:

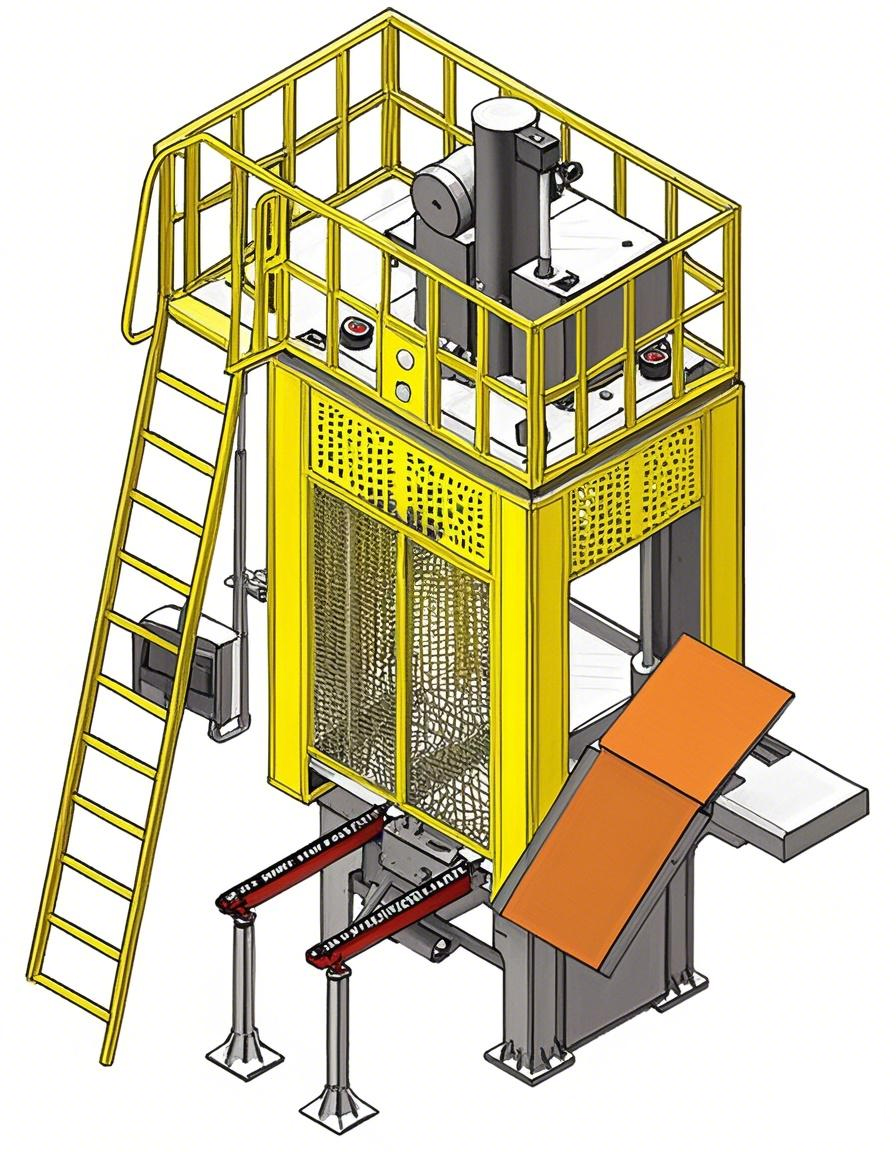

Four-Post Three-Plate Structure: Heat-treated platens resist wear over 500,000 cycles, while precision-guided bushings ensure dicrease verticality error , surpassing industry standards for geometric accuracy.

Motorized Height-Adjustable Table: 0–200mm range enables quick mold changeovers, reducing setup time by 50% compared to manual systems and enhancing flexibility for mixed material processing on this hydraulic forming press.

HMI Touchscreen: Intuitive interface stores multiple custom recipes for one-touch recall of force, speed, and dwell time, reducing setup errors and training time .

Dual Safety Features: Interlocked guards and light curtains halt operation , ensuring operator safety during the high-force operations typical of a hydraulic forming press.

Hydraulic System: Uses anti-wear oil with change intervals and dual-stage filtration, extending pump life and minimizing downtime.

Regenerative Circuit: Recovers return-stroke energy, reducing power consumption and complying with energy efficiency standards, a key environmental benefit of this hydraulic forming press.

Unwavering Force Stability

Multi-Material Compatibility

Generous Work Envelope

The 60Ton hydraulic forming press (105-60T) stands as a testament to engineering excellence, combining 600KN of reliable force with precision controls and a robust design. Ideal for mid-heavy industrial tasks, this hydraulic forming press handles diverse materials with consistency, efficiency, and adaptability, making it an indispensable asset for manufacturers across automotive, industrial equipment, and composite sectors. Its advanced features—from intelligent controls to energy-efficient hydraulics—position it as a leader in medium-load forming solutions, delivering the performance and durability required for modern, high-volume production environments.

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.