BQ-L Aluminum Wheel Hub Low-Pressure Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The BQ-L Aluminum Wheel Hub Series is a state-of-the-art solution engineered for high-efficiency production of lightweight, high-strength alloy wheels.

Overview

Designed for automotive and commercial vehicle applications, this machine integrates gravity-assisted filling technology to ensure defect-free castings with superior surface finish and structural integrity. Its advanced automation and energy-efficient design cater to the demands of mass production while minimizing operational costs.

Core Technical Features

1.Gravity-Assisted Filling

The gravity-assisted filling system positions molds vertically at 90°, leveraging natural gravitational force to optimize molten aluminum flow. This reduces turbulence and porosity in critical areas like wheel spokes , achieving a first-pass yield rate. The gravity-assisted filling process is particularly effective for large-diameter wheels (18–24 inches), ensuring consistent wall thickness.2.High-Precision Pressure Control

A multi-stage digital pressure valve system maintains deviations ≤1 mbar during filling and solidification. Combined with gravity-assisted filling, this guarantees uniform metal distribution, even for ultra-thin sections (3–5 mm thickness), meeting stringent automotive quality standards.

3.Automated Workflow Optimization

Robotic arms extract castings within 10 seconds post-solidification, while integrated mold spraying and slag removal systems eliminate manual intervention.4.Energy-Saving Hydraulic System

Variable frequency drives (VFD) reduce energy consumption compared to conventional systems. The gravity-assisted filling technology further minimizes material waste, with closed-loop scrap recycling achieving aluminum reuse.5.Durable Thermal Management

Insulation furnaces feature a monolithic refractory lining, ensuring a service life of 5+ years. PID temperature control (±2°C) maintains molten aluminum oxidation below 0.5%, critical for high-gloss wheel surfaces.

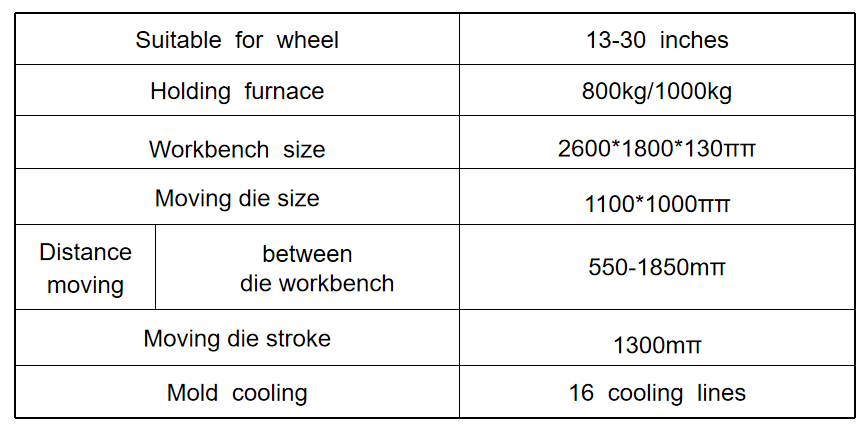

Technical Specifications

Applications

--Passenger Vehicles: Lightweight alloy wheels with zero surface defects.

--Commercial Trucks: High-load-capacity 6-bolt hubs, enhancing durability by 20%.

--Specialty Wheels: Explosion-proof and snow tire-optimized designs enabled by gravity-assisted filling precision.

The BQ-L aluminum wheel hub special-purpose machine is standardized mass-production equipment. It addresses the high-performance requirements of symmetrical structural components like wheel hubs by optimizing the filling path and enhancing feeding and cooling efficiency.Address the filling uniformity and feeding efficiency of complex structures such as wheel hub spokes and rims to avoid shrinkage porosity and gas porosity defects.