BQ-L Engine low pressure die casting machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The BQ-L Engine Cylinder Head & New Energy Series is a cutting-edge solution designed for high-precision production of complex aluminum alloy components in automotive powertrains, electric vehicles (EVs), and aerospace applications.

Overview

Central to its innovation is multi-zone thermal regulation, a technology that ensures uniform temperature distribution across intricate geometries, enabling defect-free castings with enhanced mechanical properties. This machine combines ultra-high rigidity, adaptive automation, and sustainability to meet the demands of next-generation manufacturing.

Core Technical Features

1.Multi-Zone Thermal Regulation

The system divides molds into 12 independently controlled cooling zones, each with ±1°C accuracy. AI algorithms dynamically adjust cooling rates based on real-time thermal profiles, eliminating hot spots and shrinkage in critical areas like cylinder head combustion chambers. Ensures uniform microstructure formation, boosting tensile strength compared to conventional methods.2.Multi-Angle Mold Flexibility

Molds can be mounted at 90°, 45°, or custom angles to optimize molten metal flow for irregular geometries. Paired with multi-zone thermal regulation, this feature reduces air entrapment in thin-walled EV battery enclosures and aerospace brackets.

3.Ultra-High Pressure Precision

Servo-electric actuators maintain pressure stability during filling and solidification. The multi-zone thermal regulation system synchronizes with pressure sensors to prevent micro-porosity, achieving near-net-shape accuracy for components like turbocharger housings.4.Industry Integration

IoT-enabled interfaces collect real-time data on cycle times, energy use, and defect rates. Multi-zone thermal regulation profiles are stored in a cloud-based library, enabling rapid setup changes for high-mix, low-volume production.5.Eco-Efficient Heat Recovery

Up to 70% of residual heat is recycled to preheat molds or auxiliary systems, reducing energy consumption. The multi-zone thermal regulation technology minimizes scrap rates, supporting global carbon-neutral initiatives.

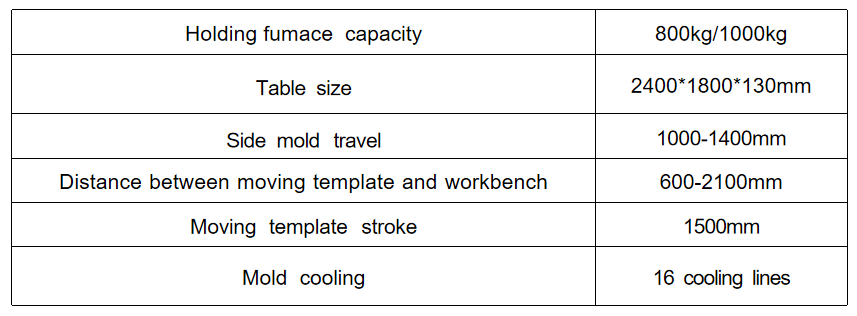

Technical Specifications

Applications

--EV & Energy Storage: Battery trays, motor housings, charging port frames.

--Aerospace: Satellite mounts, turbine blade connectors, avionics heat sinks.

--Heavy Industry: Hydraulic valve blocks, robotic arm joints, CNC machine bases.

The BQ-L specialized machine for engine cylinder heads and new energy castings is flexible customized equipment, with multi-mode cooling and precise pressure stage control as the core, tackling the differentiated process challenges of complex structural components.Process focus on address multi-zone cooling requirements (such as conformal cooling for cylinder head water jackets) and thin-wall filling stability to prevent cold shuts and misruns. Achieve the balance between lightweighting and high strength for new energy castings (e.g., battery pack casings requiring impact resistance and corrosion resistance).