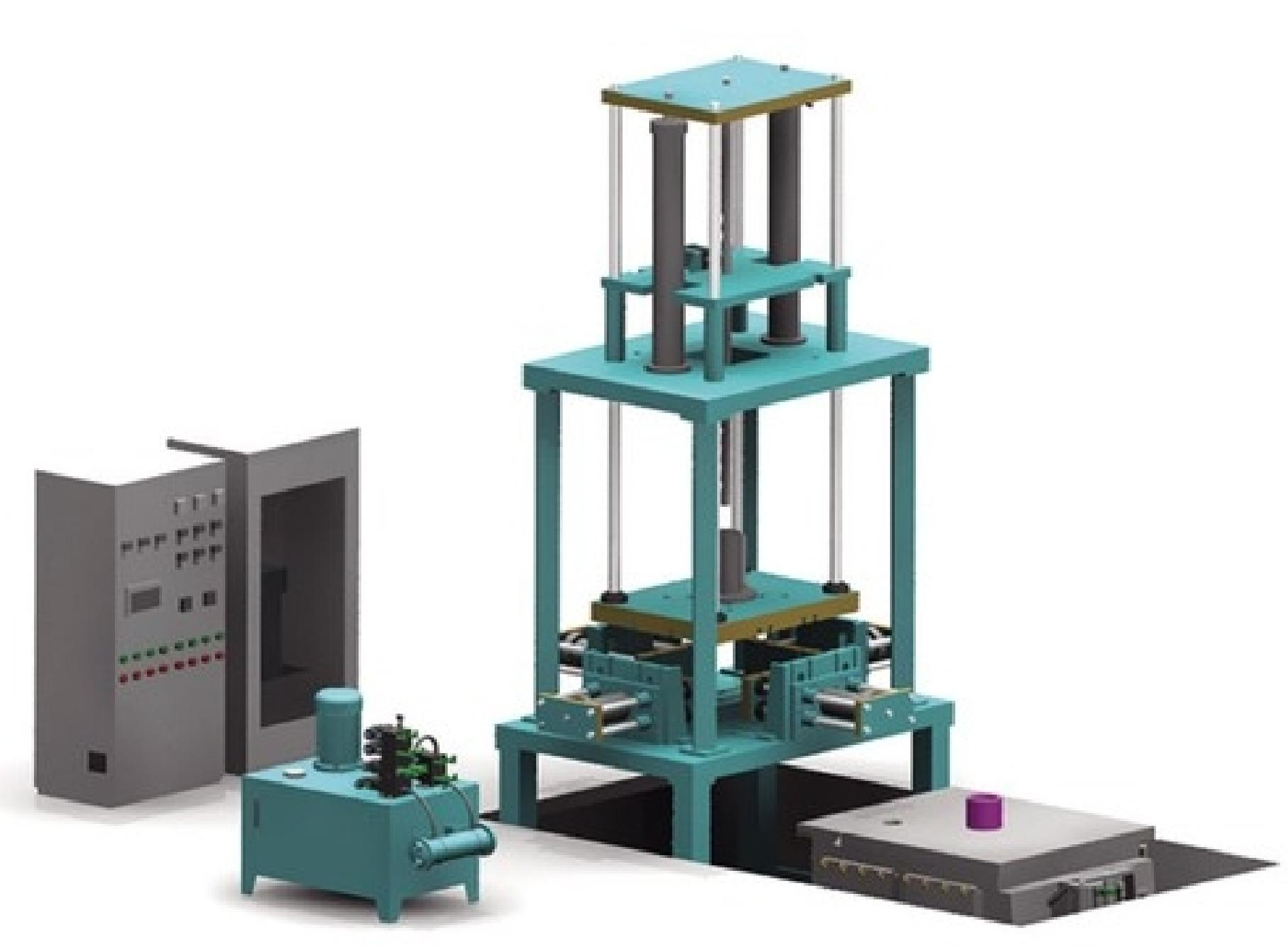

BQ-L Series Low-Pressure Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The BQ-L Series is a next-generation solution tailored for high-performance aluminum alloy castings in aerospace, electric vehicle (EV), and precision machinery industries.

Overview

Designed with adaptive thermal management technology, this machine ensures superior structural integrity for complex components like battery housings, steering knuckles, and aerospace brackets. Its modular architecture and intelligent control systems redefine precision, flexibility, and sustainability in modern foundry operations.

Core Technical Features

1.Adaptive Thermal Management

The adaptive thermal management system employs real-time temperature monitoring across 12 independent zones within the mold. Using AI-driven algorithms, it dynamically adjusts cooling rates to eliminate hot spots and shrinkage defects. For example, EV battery trays achieve uniform wall thickness while reducing cycle time.2.Multi-Angle Mold Configuration

Supporting 90°, 45°, or custom angles, this feature optimizes molten metal flow for irregular geometries. The adaptive thermal management system synchronizes with mold orientation, ensuring consistent filling for thin-walled parts like heat sinks or drone motor casings.

3.Ultra-High Rigidity Frame

A reinforced steel frame (12,000 kN clamping force) minimizes deflection during high-pressure casting. Combined with adaptive thermal management, it enables repeatable accuracy for components requiring fine tolerances.4.Closed-Loop Pressure Control

Servo-electric actuators maintain pressure stability during filling and solidification. The adaptive thermal management system integrates with pressure sensors to prevent micro-porosity in critical zones, enhancing tensile strength by 15% compared to conventional methods.5.Energy Recovery System

Up to 70% of residual heat from molten aluminum is reclaimed to preheat molds or auxiliary systems, slashing energy consumption. The adaptive thermal management technology ensures optimal heat distribution, further reducing carbon footprint.

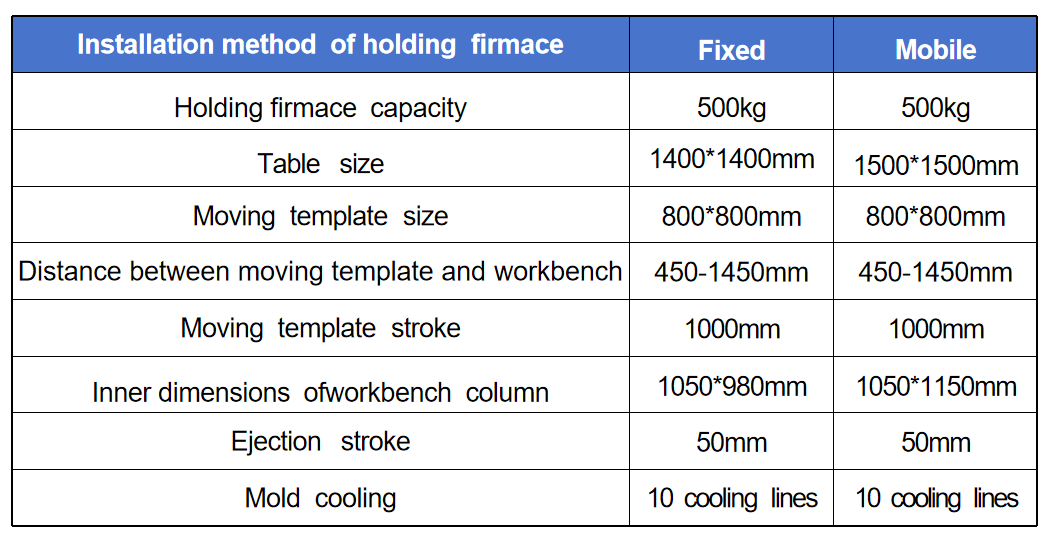

Technical Parameter

Applications

--EV & Renewable Energy: Battery enclosures, motor housings, charging port frames.

--Aerospace: Landing gear components, satellite brackets, turbine blade mounts.

--Industrial Automation: Robotic arm joints, hydraulic valve blocks, CNC machine parts.

The BQ-L Series’ adaptive thermal management technology elevates casting quality while reducing scrap rates. Its compatibility enables seamless integration into smart factories, offering real-time analytics for predictive maintenance. It features energy efficiency, flexibility, and reliability. It is an ideal choice for foundry enterprises to improve production efficiency, reduce costs, and ensure product quality.