CM Series Hot Chamber Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

Specialized in micro die casting machinery, the CM Series combines compact design with rapid cycle technology to deliver high-precision solutions for small zinc alloy parts.

With ±0.1mm mold positioning and intelligent controls, these machines optimize productivity for medical devices, watches, and other micro-component industries across 30-280-ton clamping force.

Core Features

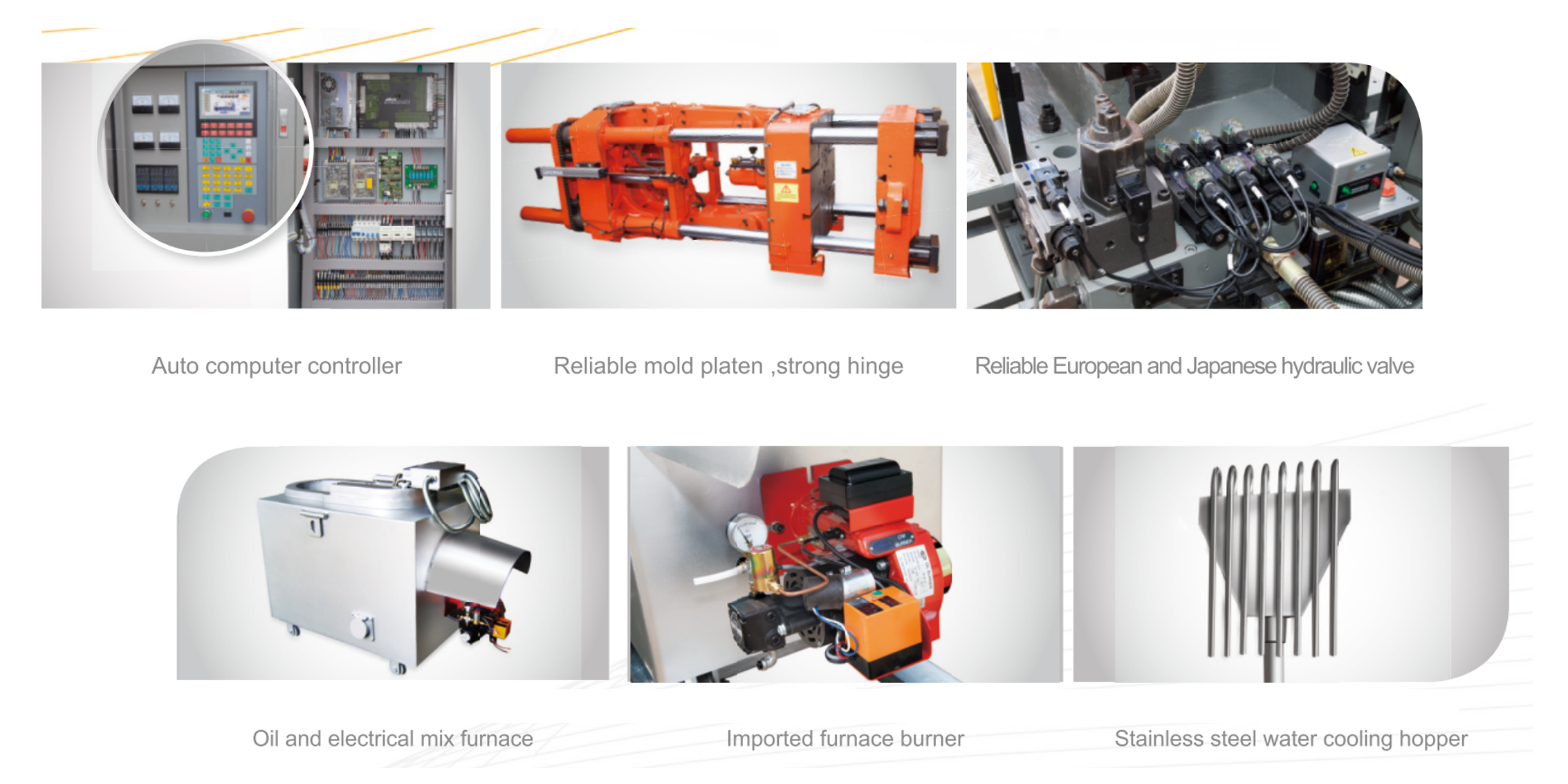

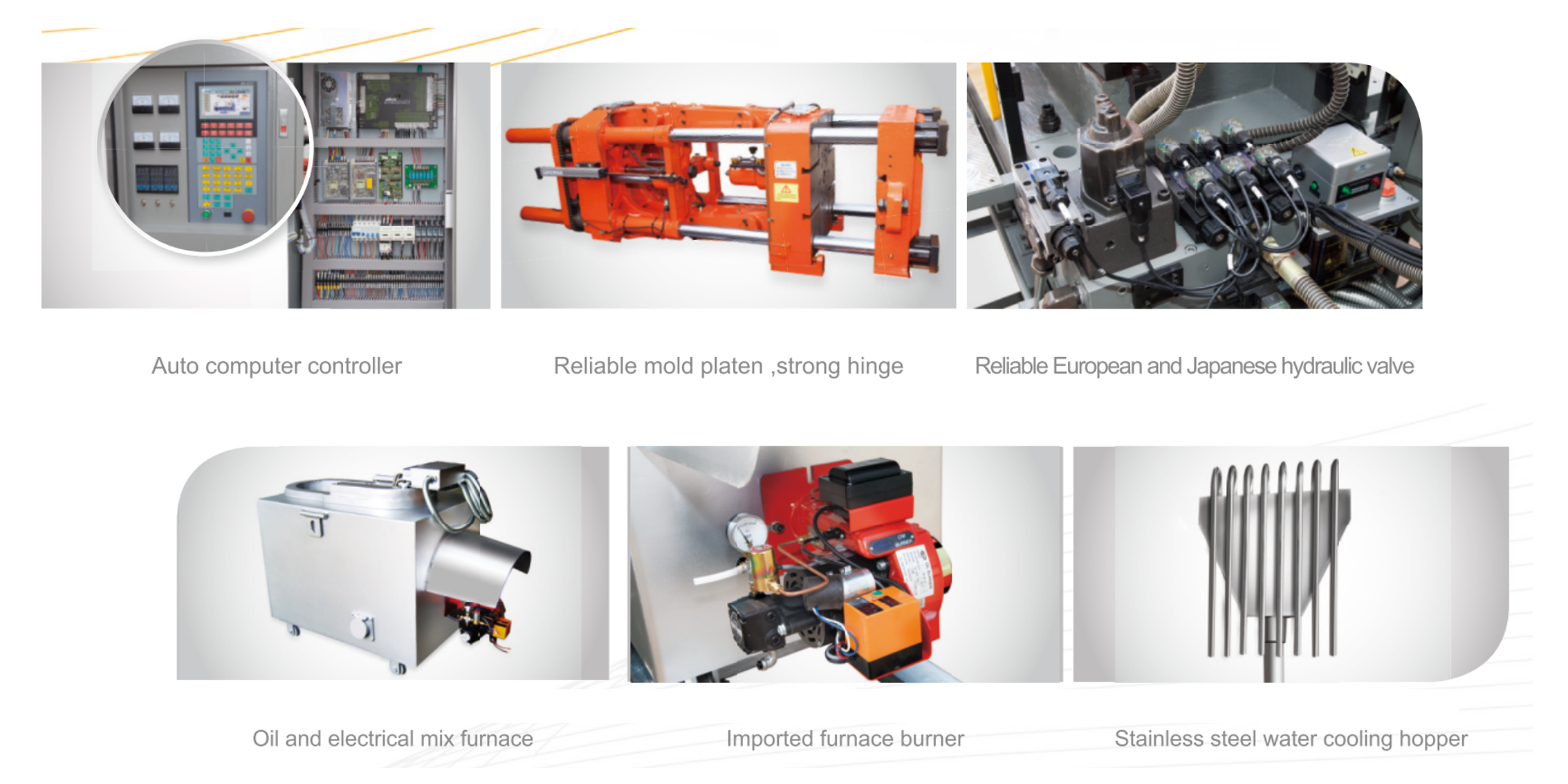

1. Standard Configuration

| System | Technical Specifications | Advantages for Micro Die Casting |

|---|

| Control System | Touchscreen, several mold parameter storage, USB interface | mold changeover critical for micro die casting efficiency |

| Hydraulic System | Gear-type mold adjustment (±0.05mm accuracy), low-noise pump (<=75dB) | Faster mold setup for frequent micro-mold changes |

| Clamping System | Compact design with rapid clamping (cycle time <=1.8s) | High-volume micro die casting |

| Safety System | Dual mechanical limits and emergency stop (<=0.5s response) | Protection for operator safety in micro die casting |

2. Optional Upgrades

| Module | Technical Specifications | Enhancements for Micro Die Casting |

|---|

| Automation | Micro robot (

- 3kg payload, ±0.03mm repeatability, 4-axis motion | Yield improvement and labor cost reduction in micro die casting |

| Energy Efficiency | Variable frequency drive (

- 25% energy saving, <=50W standby power | Electricity savings for eco-friendly micro die casting machinery |

| Mold Expansion | Multi-station turntable (

- 4-8 stations, ±0.02mm positioning accuracy | Mold lifespan extension for complex micro-components |

3.Advanced Technology Deep Dive

3.1 Multi-Station Turntable System:

The CM Series offers optional micro die casting machinery reduces cycle time while maintaining ±0.02mm positioning accuracy, ideal for complex medical device parts.

3.2 Energy-Saving VFD Technology:

By integrating variable frequency drives, the CM Series achieves energy savings compared to traditional fixed-speed pumps. This not only lowers operational costs but also meets environmental standards for sustainable micro die casting.

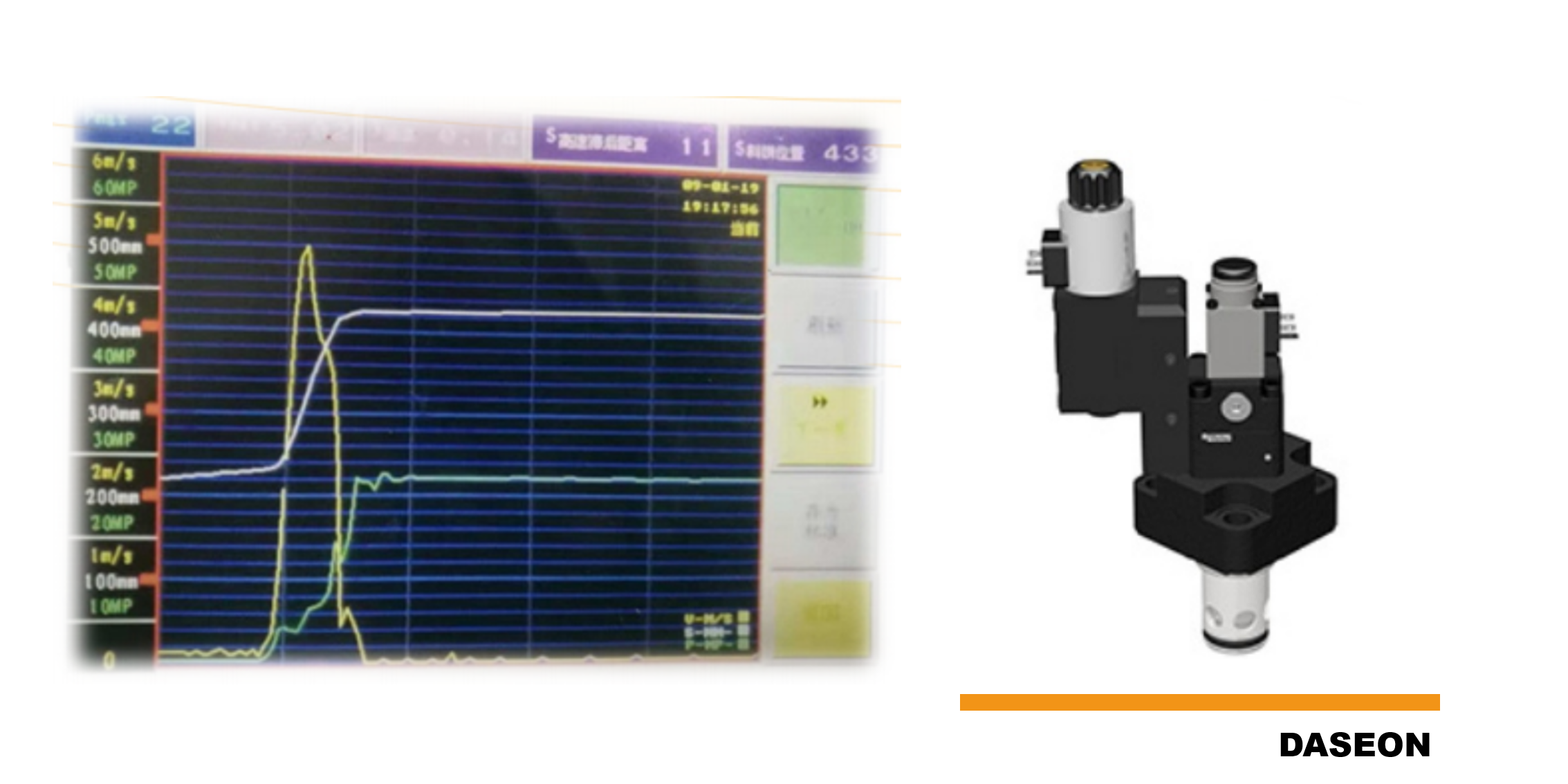

4.Micro Die Casting Machinery High end option

Intuitively display the working state of the injection system in the form of curve, which is convenient to adjust the process parameters, reduce The Times of mold test and improve production efficiency.

Adjust the injection parameters to the best state according to the data of the curve instrument to ensure the stability of product quality.

Real-time monitoring, timely detection of abnormalities, to avoid large quantities of defective products.

Helping to die casting defects analysis, clearly determine the cause of defects is mechanical or die reasons.

With the storage function, you can download the injection data of each mold on the U disk, and save and read it through EXCEL to facilitate the traceability of the quality of the die casting.

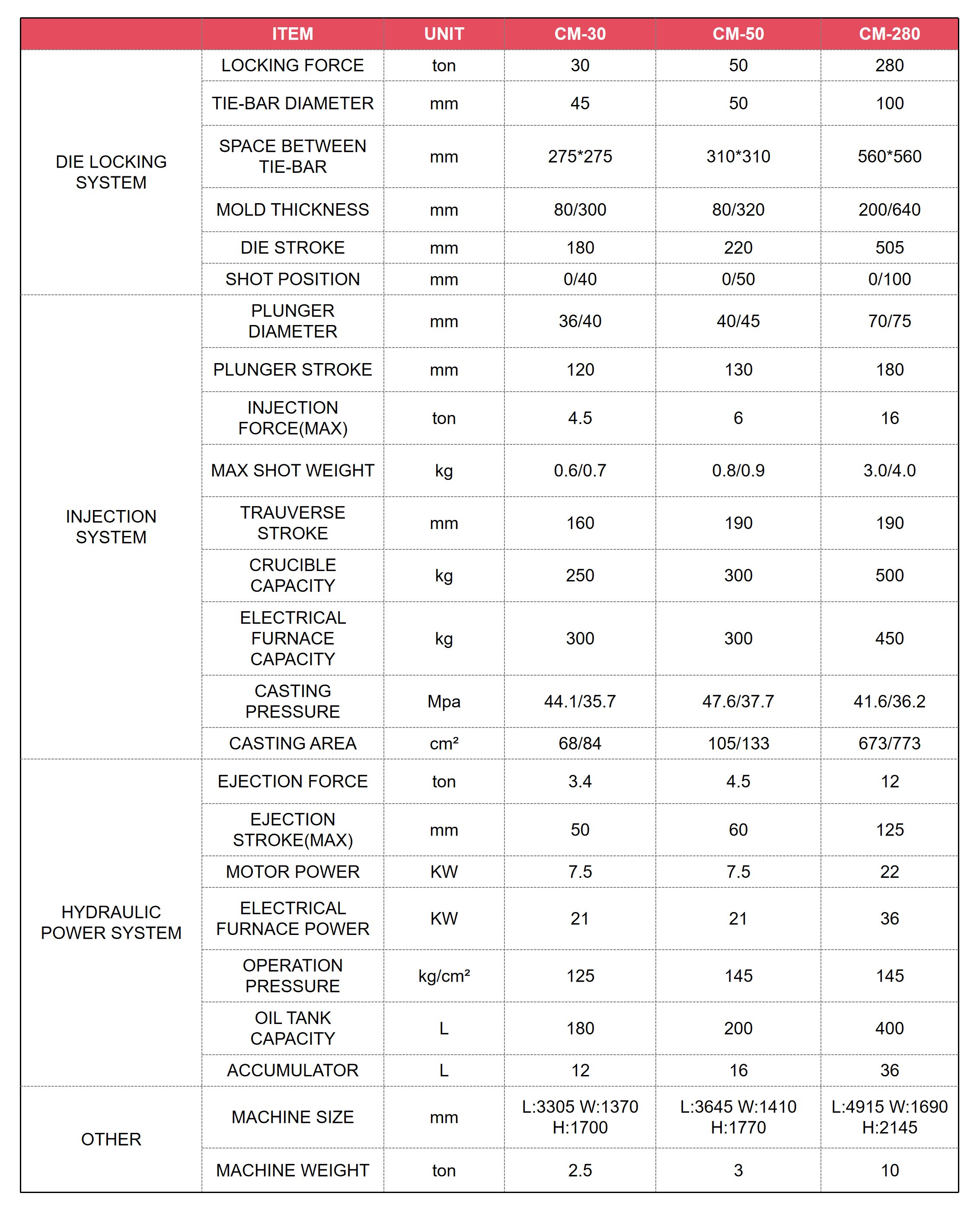

Parker's TEA Throttle is an electro-hydraulic proportional throttle unit with cut-off function. An integrated directional valve in the oil line provides safety features.

Parker's TEA series of cut-off electro-hydraulic proportional KJBV throttle units combine high flow rates and fast response to deliver superior performance.

This series of accumulator drain valve can discharge a large amount of flow from the hydraulic accumulator within a very short working cycle (within the range of a few milliseconds), for injection speed semi-closed loop control.

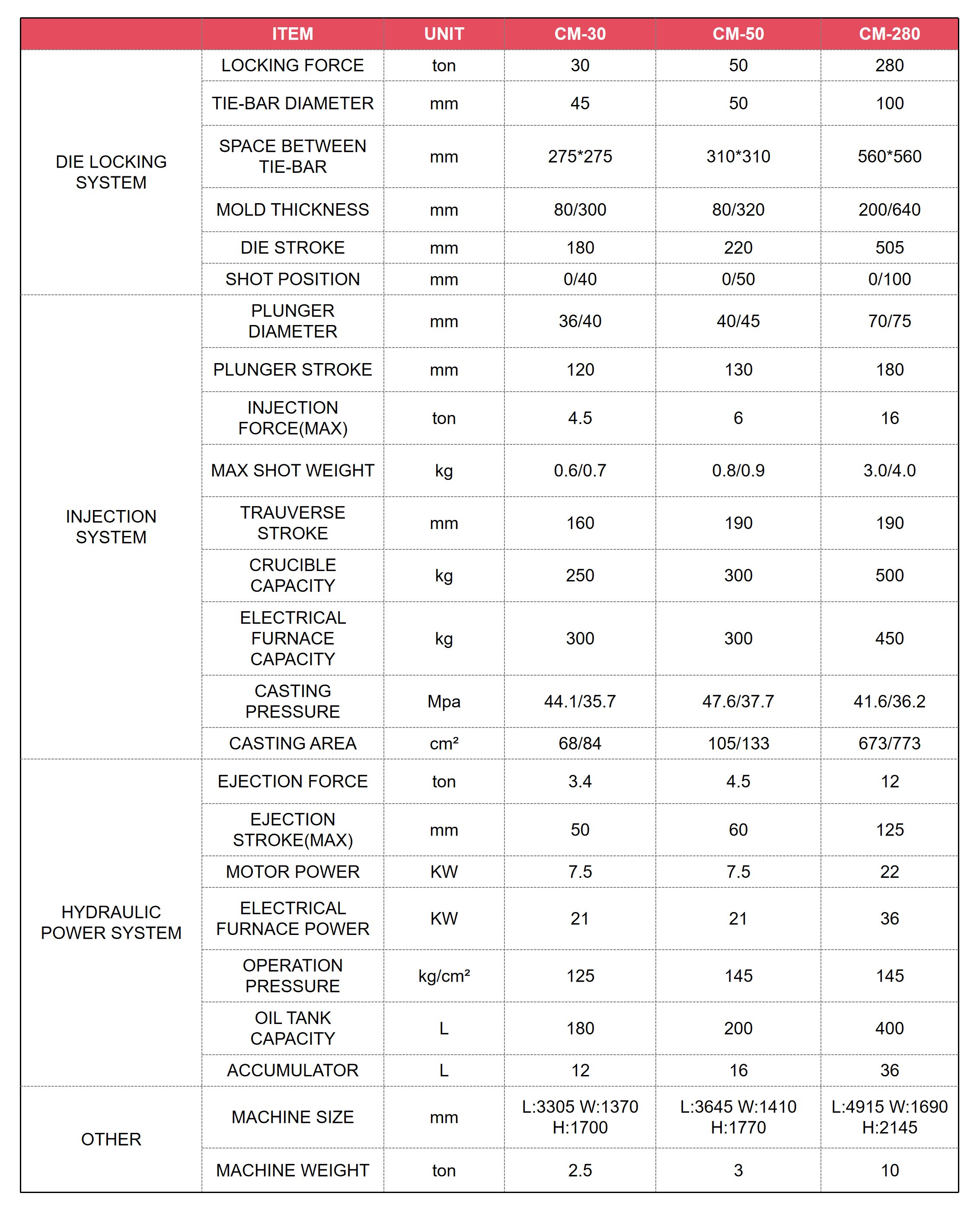

5.Micro Die Casting Machinery Parameter

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.