BQ-C Series Low-Pressure Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The BQ-C Series is engineered for the production of small-to-medium-sized aluminum alloy castings, integrating advanced hydraulic drive technology, fully automated control systems, and intelligent temperature management.

Overview

Designed to deliver precision, efficiency, and sustainability, this series is widely adopted in automotive parts, motorcycle components, and electrical fittings manufacturing. Its core philosophy centers on achieving high-pressure accuracy, energy conservation, and process flexibility to meet diverse industrial demands.

Core Technical Features

1.Anti-Adhesion Structure

The BQ-C Series employs specialized surface treatment technology to minimize oxidation and aluminum adhesion during molten metal contact. Enhanced mold coatings improve surface finish and reduce scrap rates, making it ideal for precision components such as hydraulic pump housings and valve bodies.2.Digital Servo Hydraulic System

Equipped with high-response servo valves and a PLC-based control system, the hydraulic drive ensures precision motion control. A variable frequency drive (VFD) reduces energy consumption by compared to conventional systems.

3.Dynamic Pressure Compensation

The dynamic pressure compensation system utilizes digital valve clusters to maintain pressure deviations ≤3 mbar during filling and solidification phases. This technology automatically adjusts for molten aluminum level fluctuations, gas pipeline variations, and furnace micro-leakage, ensuring consistent casting quality. The dynamic pressure compensation function reproduces preset pressure curves with high accuracy, critical for defect-free castings in aerospace and automotive applications.4.Fully Automated Production Cycle

From mold clamping, metal injection, pressure holding, to part ejection, the entire process requires no manual intervention. Multi-channel mold cooling systems support water- or air-based cooling, automatically adjusting rates based on part geometry.5.Modular Configuration Options

The BQ-C Series offers flexible configurations, including 200–1,500 kg capacity holding furnaces (radiant or crucible-type) and 90° or 45° mold mounting orientations. Users can toggle between manual and automatic modes—manual for prototyping and automatic for high-volume production—ensuring adaptability across batch sizes.

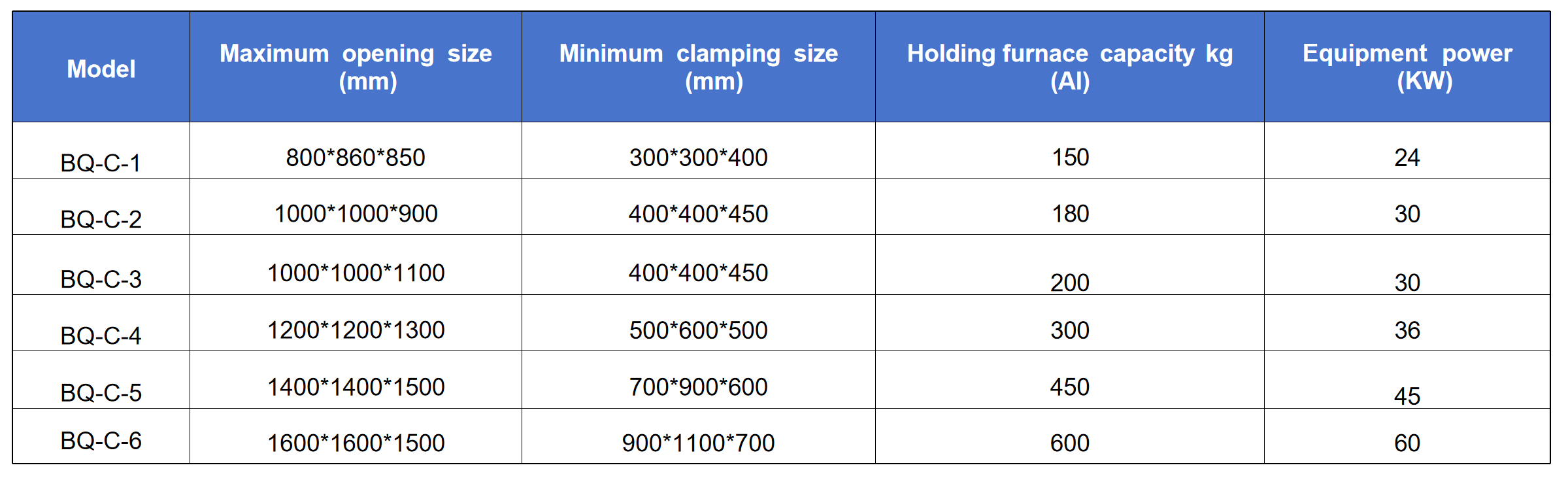

Technical Specifications

Applications

1.Automotive: Engine cylinder heads, transmission housings, steering knuckles

2.Electrical: Insulator flanges, cable connectors

3.Motorcycle: Cylinder heads, shock absorber housings

4.Industrial Machinery: Hydraulic couplers, gearbox castings

Value Proposition

The BQ-C series, centered around precise control, high - efficiency energy conservation, and flexible adaptation, offers comprehensive support for small and medium - sized casting enterprises from process design to mass production. With its advanced dynamic pressure compensation technology, it helps to boost production capacity, optimize product quality, and reduce costs. It is an ideal choice for both traditional manufacturing and emerging industries.