High Speed Disperser for paint, ink

Brand :CAREER

Product origin :China

Delivery time :20 days after receiving down payment

Supply capacity :100unit/month

high speed disperser is widely applied in dispersing paste such as color paint paint, ink, dye, adhesion, ceramic glaze, magnetic recording materials etc.

high speed automatic paint mixer manufacturer

1. Application:

high speed disperser is widely applied in dispersing paste such as color paint paint, ink, dye, adhesion, ceramic glaze, magnetic recording materials etc. Disperser is the a good solution for mixing, dispersing and dissolving.

2. Working Principle:

Pigment Paste Material will be stirred up-down by the high-speed rotation force of disperser/dissolver. Material will be crushed and cut by the impeller and the aggregates will be broken and dispersed rapidly.

3. Machine Features

1) Reasonable shape design of the high speed disperser makes the machine more stable, easy to operate and maintain.

2) Electrical hydraulic lifting for easy operation

3) High speed main shaft, basket head, belt pulley has passed the static and dynamic equilibrium test

4) The high-speed pigment disperser has been equipped with double-layer cylinder to avoid hydraulic oil leakage after long time using.

5) Belt clamp or manual clamp or pneumatic clamp devices can be set for the vessel as per clients requirements.

6) With CE&ISO9001 qualification

4.Technical specifications

| Model | Motor Power (W) | Speed (rpm) | Capacity (L) | Disc Diameter (mm) | Lifting Stroke mm) |

| KR-FS-5.5 | 5.5 | 0-1400 | 100-200 | 200 | 600 |

| KR-FS-7.5 | 7.5 | 0-1440 | 100-300 | 250 | 800 |

| KR-FS-11 | 11 | 0-1440 | 100-400 | 250 | 800 |

| KR-FS-15 | 15 | 0-1440 | 100-500 | 300 | 900 |

| KR-FS-18.5 | 18.5 | 0-1440 | 400-800 | 300 | 1100 |

| KR-FS-22 | 22 | 0-1440 | 400-900 | 300 | 1100 |

| KR-FS-30 | 30 | 0-1440 | 400-1000 | 350 | 1100 |

| KR-FS-37 | 37 | 0-1440 | 800-1200 | 400 | 1100 |

| KR-FS-45 | 45 | 0-1440 | 800-1400 | 450 | 1500 |

| KR-FS-55 | 55 | 0-1100 | 1000-1500 | 500 | 1500 |

| KR-FS-75 | 75 | 0-1000 | 2000-4000 | 550 | 1700 |

5. Packaging and delivery

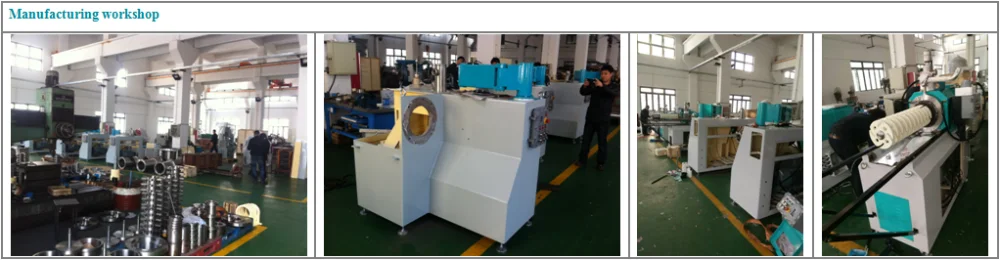

6: Workshop

Modern Nano Laboratory

Lab Experiment Equipments: disperser(1.1kw), lab sand mill, ceramic sand mill, laser granulometer

Experiment Process:

1) Material information

2) Experiment preparation

3) Experiment mode confirm

4) Experiment execute

5) Report Generate

6) Sending test products to clients

If you want to do experiment of your material, pls contact us and make an appointment with our sales engineer.