Liquid Detergent Production Line

Brand :CAREER

Product origin :China

Delivery time :20 days after receiving down payment

Supply capacity :10 lines /month

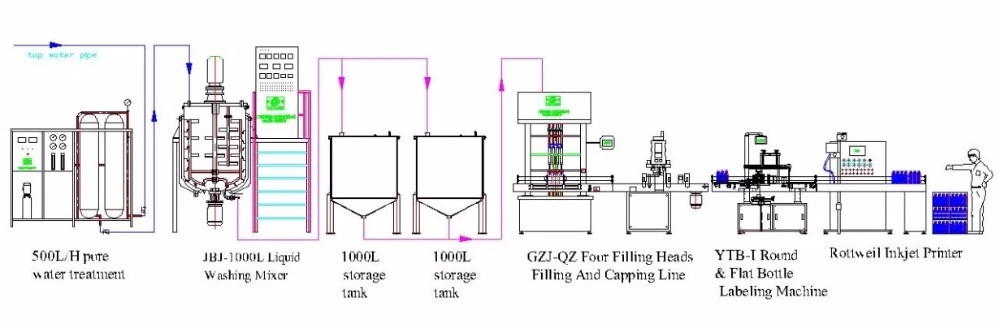

This line is suitable for manufacturing liquid products (such as detergent, shampoo, shower gel etc.)

Liquid Detergent Production Line

Brief description

This line is suitable for manufacturing liquid products (such as detergent, shampoo, shower gel etc.) it integrates mixing, homogenizing, heating, cooling, pump discharge finished products and defoaming (optional) functions. It is the ideal equipment for liquid products in domestic and international factories.

Features and Advantages

1. The all-round wall scraping mixing adopts the frequency converter for speed adjustment, so that to produce high quality products of different processes according to customer requirements.

2. the self-suction type AES dissolver can shorten dissolving time, so as to save energy consumption and shorten production period.

3. The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.

4. Various forms of blending vanes are suitable for production of different types of products.

5. According to technological requirement, the tank can heat and cool materials. The heating way including steam heating and electric heating.

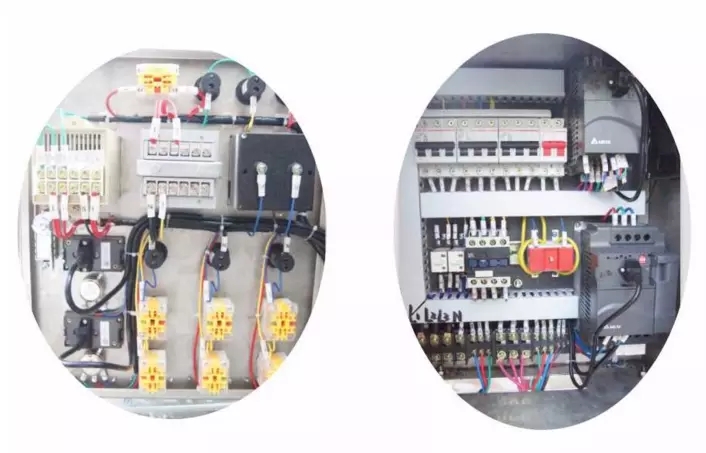

6. Advanced SIEMENS PLC touch screen control is optional.

Technical parameter

| Model | Capacity(L) | mixing power(kw) | Mixing Speed(r/min) | Homogenizing power(kw) | Homogenizing speed(r/min) | Heating method |

| JT-200 | 200 | 0.75 | 0-65 | 2.2-4 | 3000 | Steam Heating or Electric Heating (optional) |

| JT-300 | 300 | 0.75 | 0-65 | 2.2-4 | 3000 | |

| JT-500 | 500 | 2.2 | 0-65 | 5.5-7.5 | 3000 | |

| JT-1000 | 1000 | 4 | 0-65 | 7.5-11 | 3000 | |

| JT-2000 | 2000 | 5.5 | 0-53 | 11-15 | 3000 | |

| JT-3000 | 3000 | 7.5 | 0-53 | 18 | 3000 | |

| JT-5000 | 5000 | 11 | 0-42 | 22 | 3000 |

Main Features

1) Full of SUS304, contact materials parts SUS316L, GMP standard..

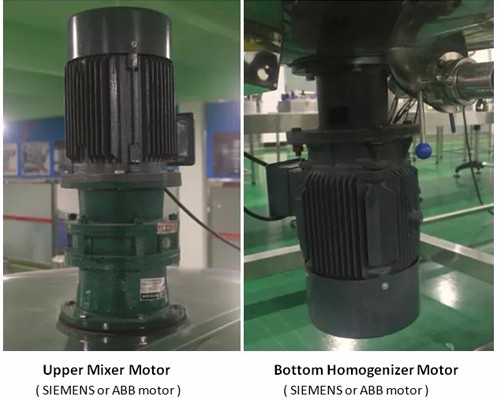

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Double jackets and insulation provide electric heating or steam heating..

4) High effection mixer and homogenizer emulsion products 2um.

5) Apply to cosmetics, shampoo, liquid soap, detergent, dish washing etc products.

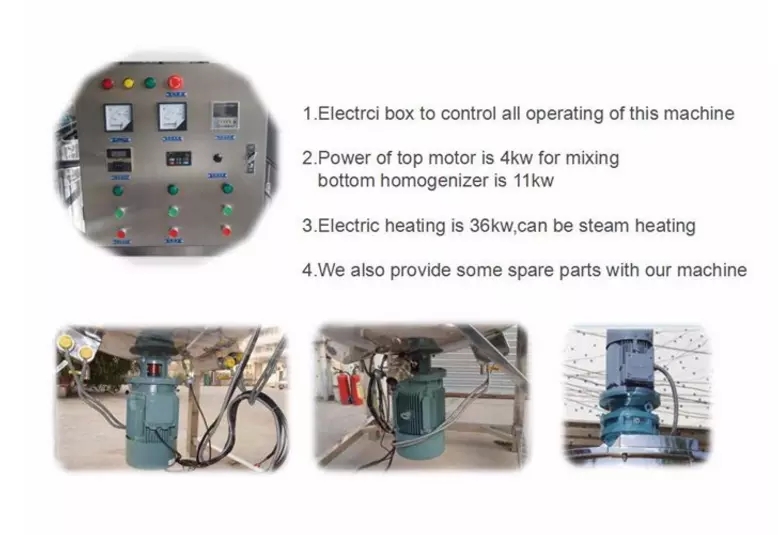

Details of machine

Factory View

Application

Packing

After-Sales Service

1, Warranty Time: one year, within this period if spare parts damage except the wrong operation , seller supply spare parts for free.We can send technician overseas for debugging machine, buyer should be responsible for necessary fee.

2, Commissioning Services: During the time of installation and debugging, our engineers will not leave, until you are satisfied with the machine.

3, Training Services: Our engineer will train your staff installation and commissioning, operation during this period if necessary.And they will not be leave until your staff can operate properly.

4, Maintenance Services: As soon as we receive your inquiry about fault, we will reply you within 24 hours

5, Lifelong Services: We provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

6, Certificate Services: we can provide certificates to customers

7,Inspection Services: Accept the third party inspection company or inspectors check the products before shipment

8,File Services: we can supply Manual Specification,Operate Video and other files you need.

More Product Information,please contact supplier !