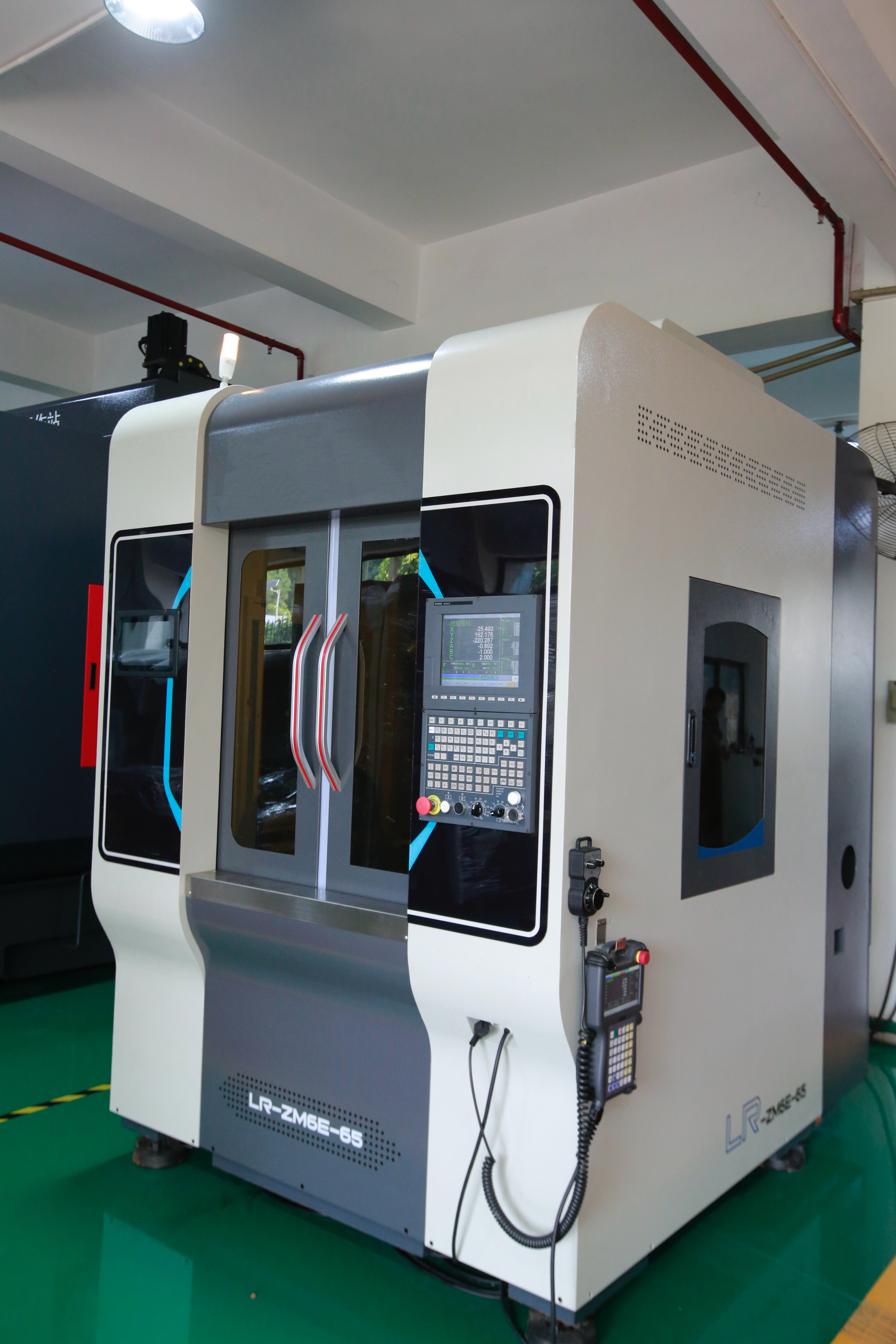

LR-ZM6B-65 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The Mid-Scale Deburring System by DASEON is the definitive solution for manufacturers seeking precision, flexibility and scalability. With SYNTEC’s advanced 6-axis control, rapid tooling adaptability, and compliance with global standards, this system streamlines workflows while maintaining rigorous quality benchmarks. From automotive transmissions to aerospace brackets, the LR-ZM6B-65 empowers industries to achieve higher throughput, lower operational costs, and consistent micron-level accuracy.

In Industrial environments focused on medium-sized components—ranging from 50mm to 700mm in diameter—there's a critical need for deburring solutions that blend precision, power, and adaptability. The LR-ZM6B-65 Mid-Scale Deburring System addresses this gap with its SYNTEC CNC-controlled 6-axis system, it bridges agility and capacity, enabling seamless processing of complex geometries like multi-cavity molds and thin-walled housings.

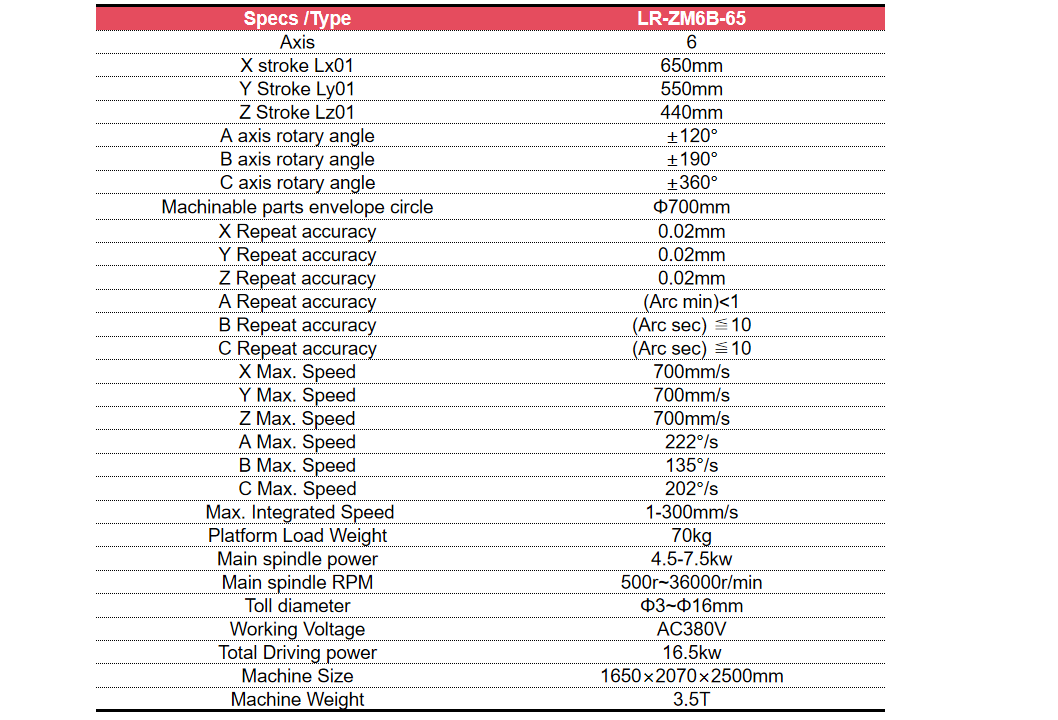

Core Technical Specifications

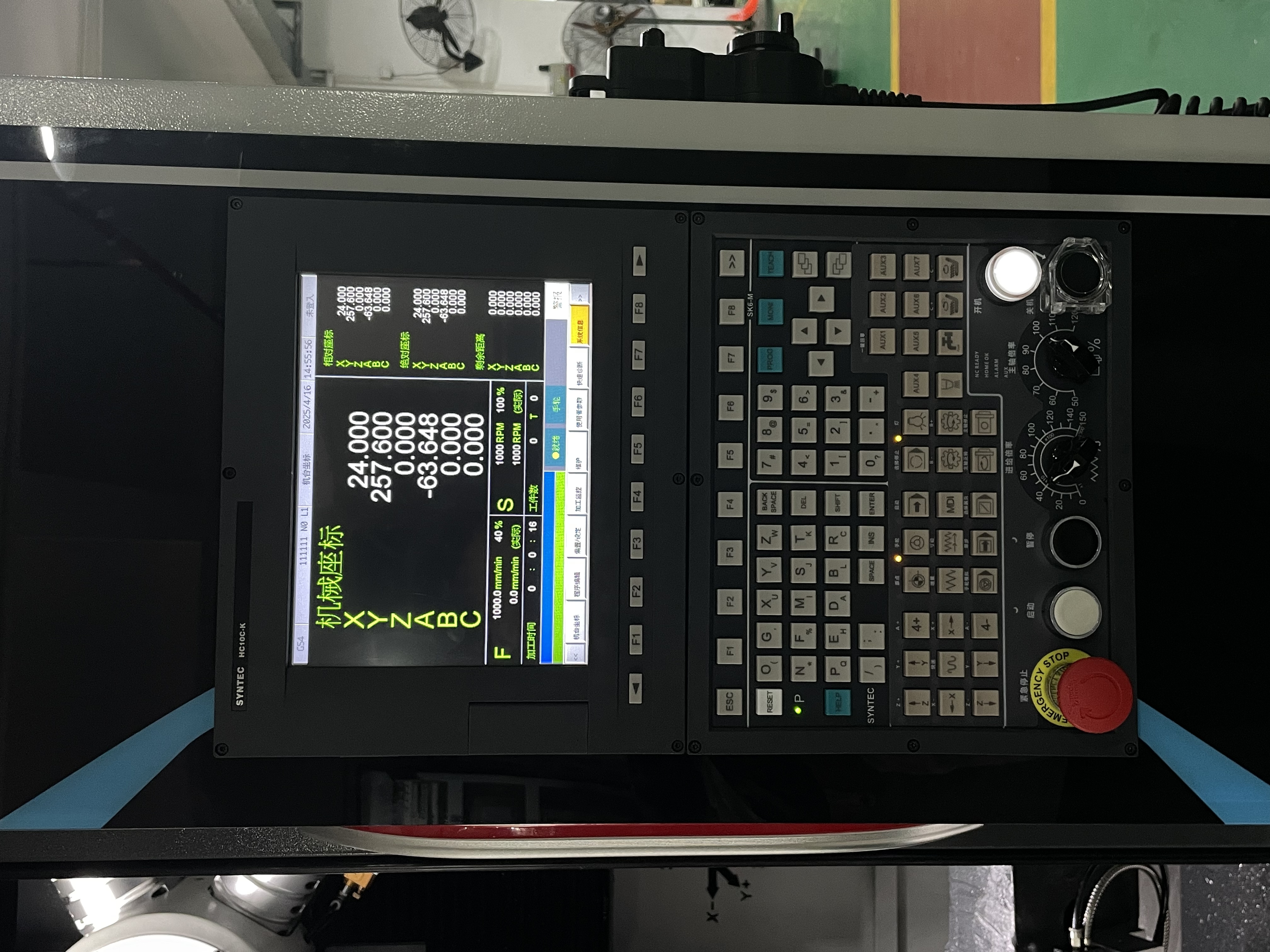

1. SYNTEC 6-Axis Control System

--Axis Configuration: X/Y/Z linear axes (650mm/550mm/440mm strokes) + A/B/C rotary axes (±120°/±190°/±360°).

--Max. Speed: 700mm/s (linear axes), 222°/s (A-axis).

--Spindle Power: 4.5–7.5kW, 500–36,000 RPM.

--Repeat Accuracy: ≤0.02mm (X/Y/Z), ≤10 arc seconds (B/C axes).

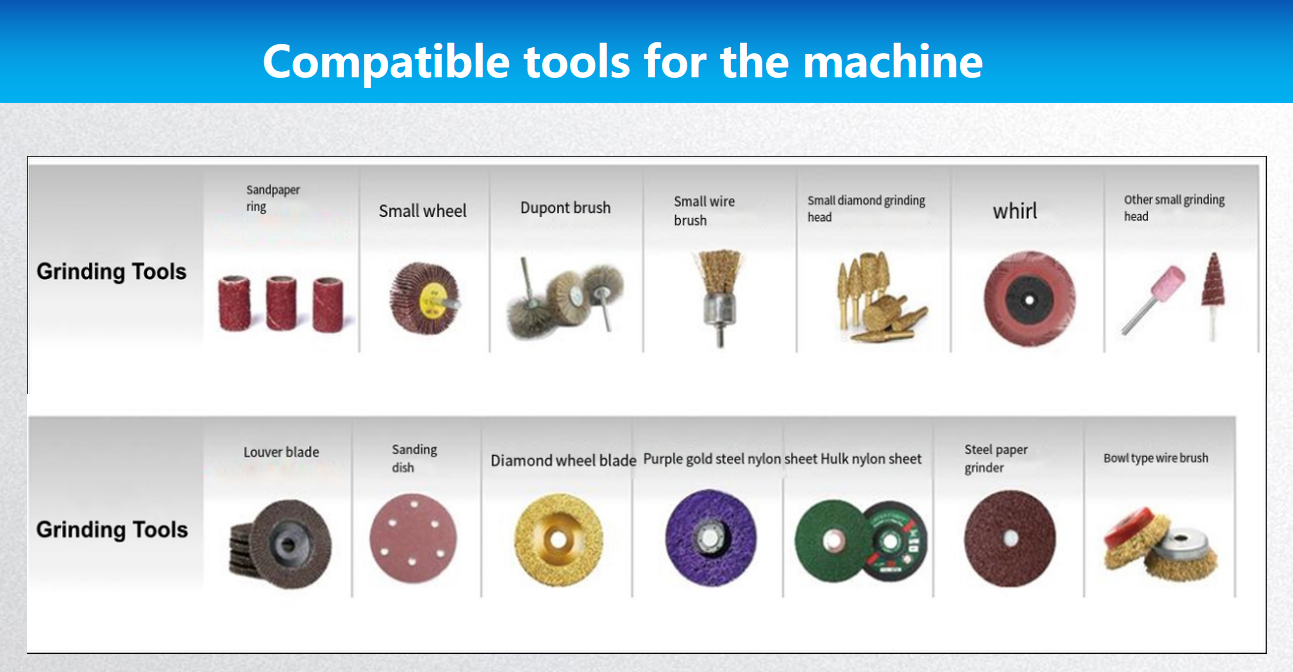

2. Advanced Tooling Solutions

--6-Station Rotary Tool Changer: Swaps rigid tools (milling cutters, reamers) and flexible tools (steel brushes, grinding wheels) in <3 seconds.

--Automatic Tool Compensation: Laser calibration adjusts for wear, extending tool lifespan (e.g., 1,500 cycles for carbide mills).

--Tool Breakage Detection: Halts operations within 0.2s to prevent defective parts.

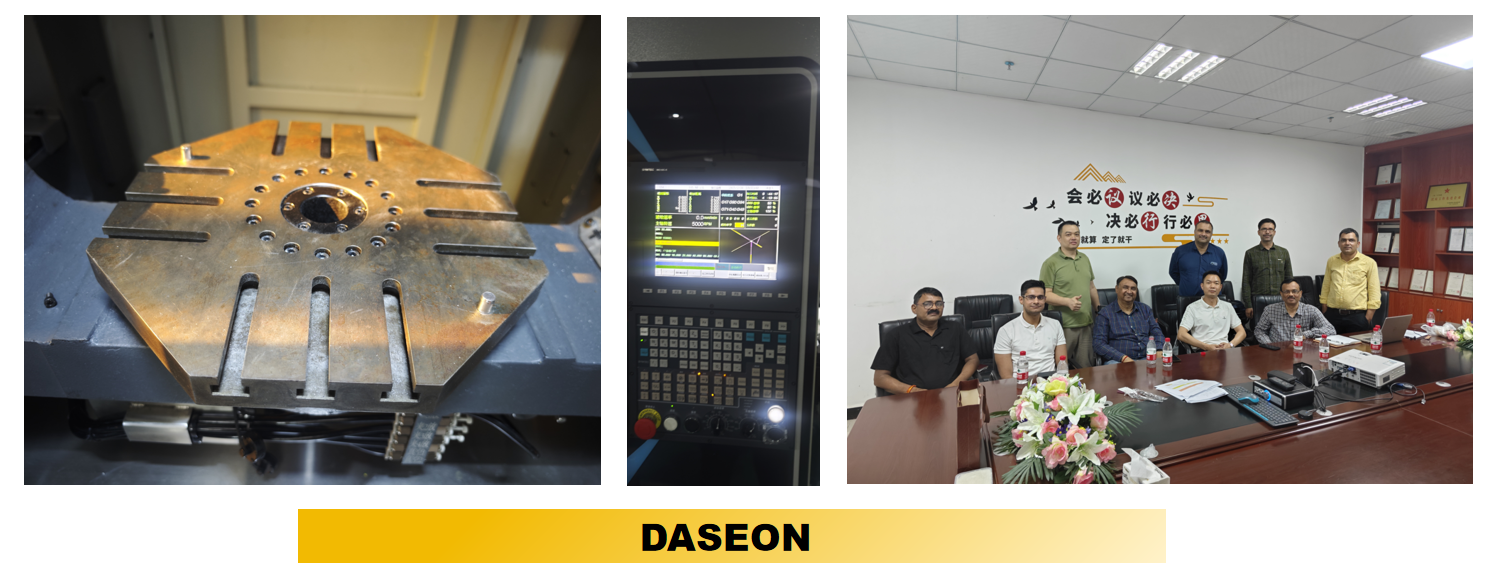

3. Workholding & Safety

--Quick-Change Fixtures: Utilizes 1:2 locating pins and pneumatic clamps for 20-minute fixture swaps.

--IP54 Enclosure: Fully enclosed design with safety light curtains and emergency stops.

Industry-Specific Applications

Automotive Manufacturing

--Transmission Housings: Deburrs gearbox castings with Ra ≤1.0μm, ensuring leak-proof seals for lubricant systems.

--EV Charging Ports: Processes aluminum housings with ≤0.03mm tolerances, meeting IATF 16949 standards.

Aerospace Components

--Turbine Brackets: Removes burrs from titanium alloys without micro-cracks, complying with FAA structural requirements.

--Hydraulic Manifolds: Cleans deep cavities (≥150mm) in steel components for 2,500 PSI systems.

Consumer Durables

--HVAC Valve Bodies: Achieves Ra ≤1.2μm on brass sealing surfaces, reducing wear in high-pressure environments.

--Industrial Pump Housings: Polishes internal channels to eliminate flow restrictions.

Parameter

Conclusion

The LR-ZM6B-65 Mid-Scale Deburring System is designed for manufacturers who prioritize consistency and efficiency. By integrating SYNTEC’s proven CNC control, 6-axis versatility, and robust construction, it delivers dependable performance for automotive parts, machinery components, and electrical enclosures—without the complexity of over-engineered solutions.

Ideal for batches ranging from 200 to 5,000 pieces, this system ensures every component meets design specifications, shift after shift. Invest in the LR-ZM6B-65 Mid-Scale Deburring System to streamline your medium-scale production and achieve new levels of process reliability.