LR-ZM6B-90 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

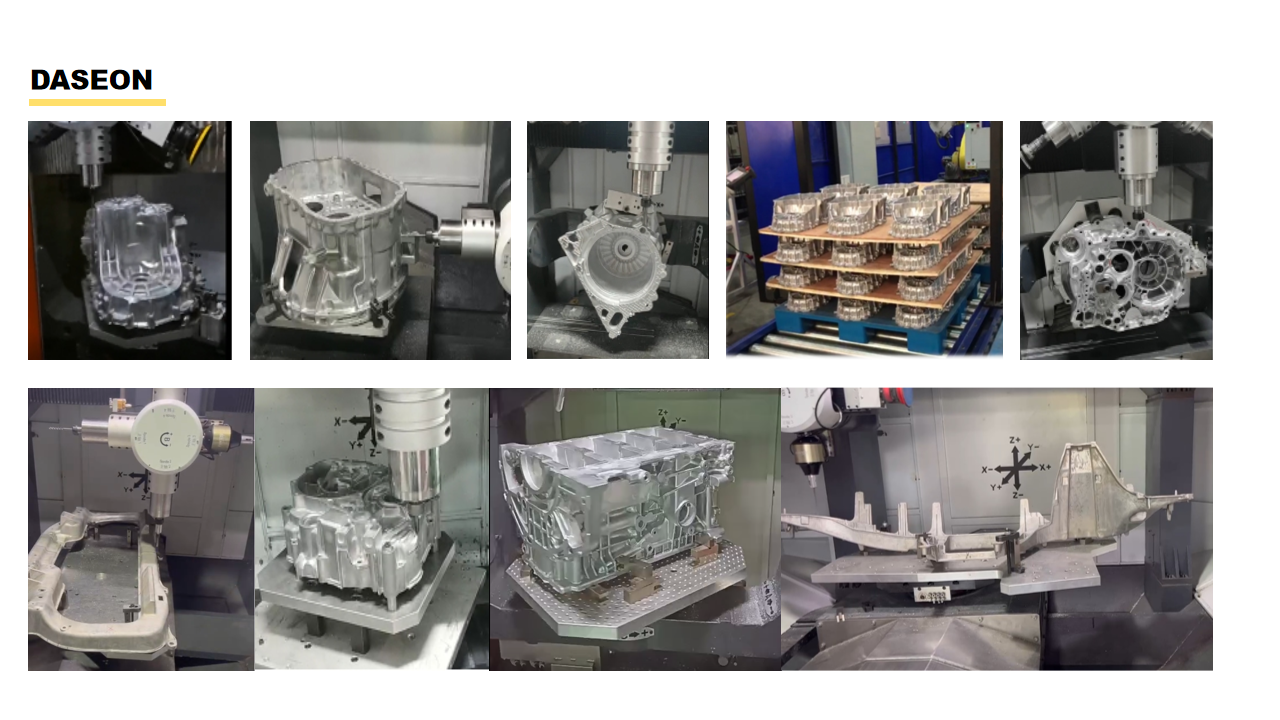

Traditional solutions struggle with the dual requirements of high-capacity workpiece handling and precision tolerances, leading to inefficiencies in both quality and productivity. The LR-ZM6B-90 High-Capacity Deburring Machine addresses this gap.

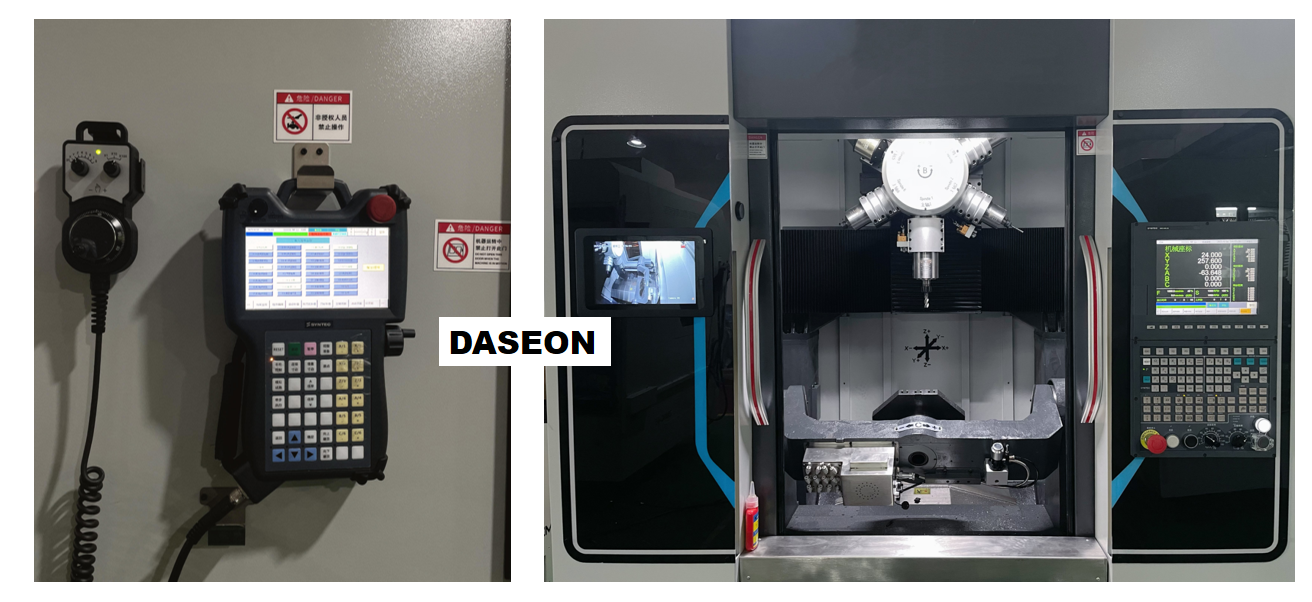

The LR-ZM6B-90 combining SYNTEC’s advanced CNC control, a robust 6-axis architecture, and a purpose-built design to process components up to φ900mm with consistent accuracy and power. Engineered for aerospace, heavy machinery, and energy sectors, this machine delivers reliable performance for batches ranging.

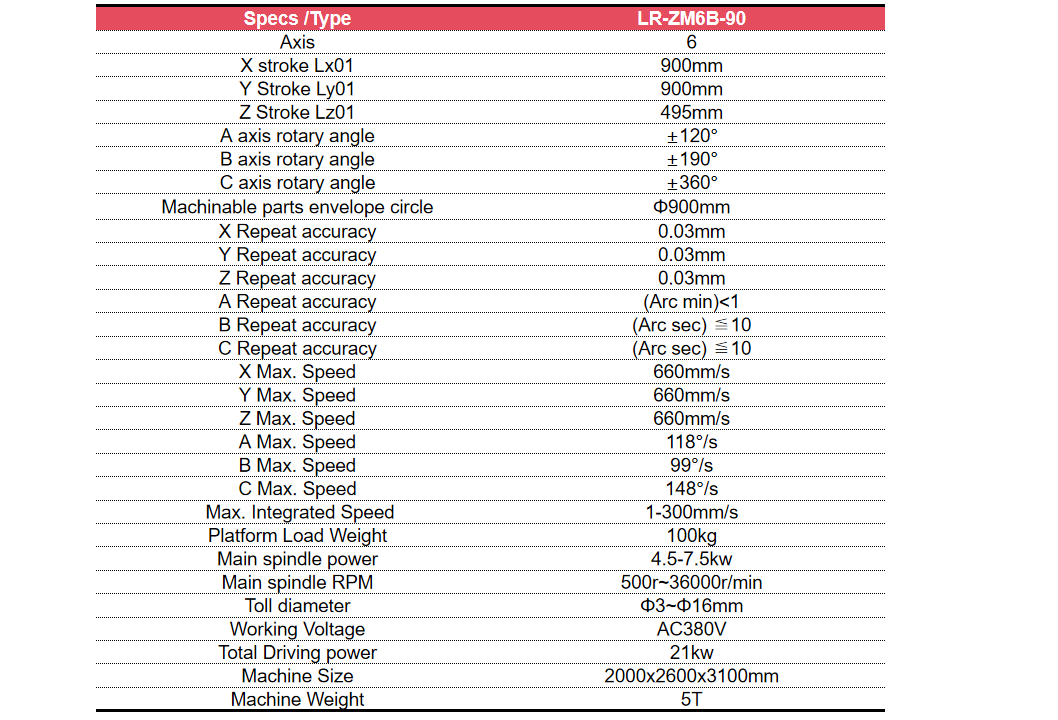

Core Technical Specifications

1. SYNTEC 6-Axis CNC System

--Axis Configuration: X/Y/Z linear axes (900mm/900mm/495mm strokes) + A/B/C rotary axes (±120°/±190°/±360°).

--Max. Speed: 660mm/s (linear axes), 148°/s (C-axis).

--Spindle Power: 4.5–7.5kW, 500–36,000 RPM.

--Repeat Accuracy: ≤0.03mm (X/Y/Z), ≤10 arc seconds (B/C axes).

2. Heavy-Duty Tooling Solutions

--Dual-Spindle Operation: The High-Capacity Deburring Machine simultaneously deploys rigid tools (Ø3–16mm carbide mills) and floating tools (steel brushes, ceramic grinders), reducing cycle times by 40%.

--Automatic Tool Compensation: Laser calibration adjusts tool wear in real time, extending lifespan (e.g., 1,800 cycles for ceramic tools).

--Tool Breakage Detection: Halts operations within 0.3s to prevent defects in high-volume batches.

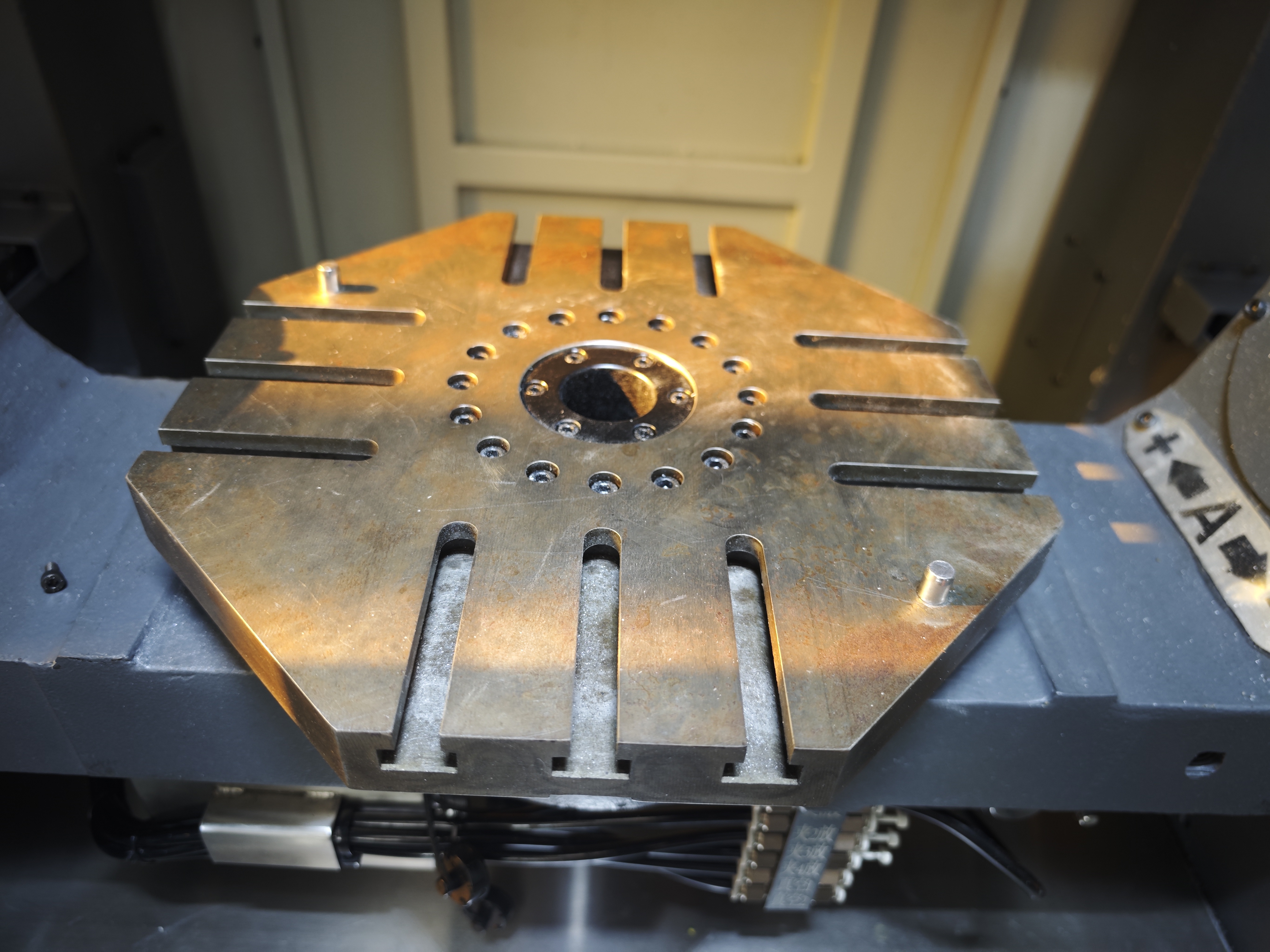

3. Robust Workholding & Safety

--Quick-Change Fixtures: Utilizes 1:2 locating pins and pneumatic clamps for 25-minute fixture swaps, tailored for large components.

--IP54 Enclosure: Reinforced cast iron frame with safety light curtains and emergency stops, compliant with EU Machinery Directive.

Industry-Specific Applications

1. EV Battery Trays

--Processes aluminum die-cast trays (Ra ≤6.3μm) with ≤0.03mm flatness, ensuring thermal management efficiency for high-performance EVs.

2. Hydraulic Manifolds

--Cleans deep cavities in steel manifolds (≥150mm) without tool deflection, meeting pressure standards.

3.Marine Engine Components

--Finishes cast iron engine blocks with ultra-hard ceramic tools, extending lifespan in corrosive environments.

Operational Efficiency for High-Capacity Production

1. Programming & Integration

3D CAM Direct Import: The High-Capacity Deburring Machine’s SYNTEC controller directly imports STEP files with embedded GD&T, generating optimized toolpaths for complex geometries in 15 minutes—4x faster than manual coding.

Industry 4.0 Connectivity: OPC UA-enabled real-time monitoring tracks spindle load, tool wear, and temperature, supporting predictive maintenance and reducing unplanned downtime in high-volume operations.

2. Practical Design for Oversized Workpieces

Expandable Workspace: With a 2000×2600×3100mm footprint and 100kg platform load, the High-Capacity Deburring Machine accommodates irregularly shaped components via custom hydraulic fixtures, which provide 5,000N holding force for stable processing.

Rapid Fixture Changes: Quick-release levers enable 3-minute fixture changes, ideal for high-capacity production lines that require frequent part type switching.

This machine is an essential investment for manufacturers seeking to optimize large-component deburring. Invest in the LR-ZM6B-90 High-Capacity Deburring Machine to streamline your production, reduce costs, and meet the most demanding industrial specifications with confidence.

Parameter