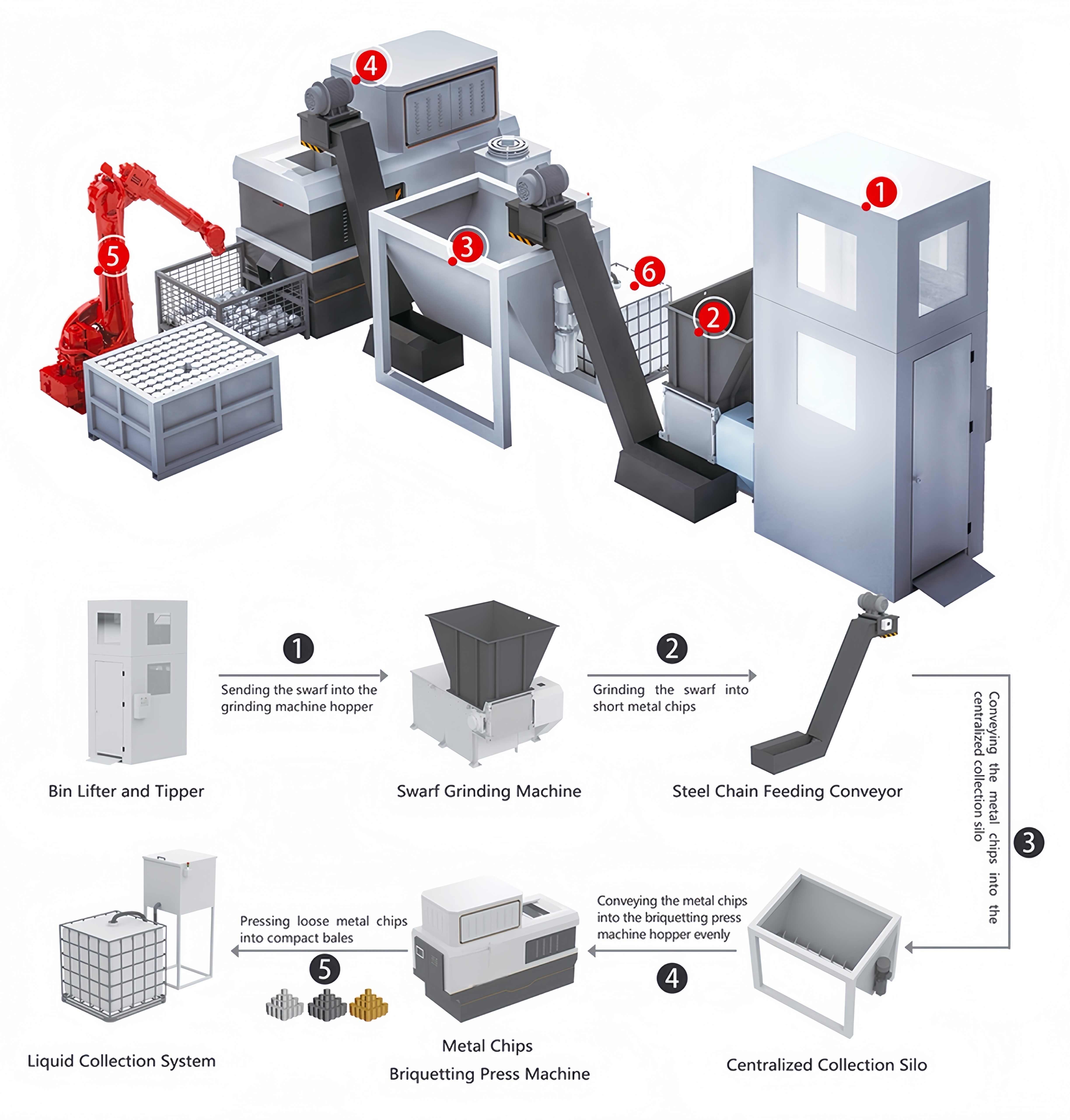

Metal Briquetting Production Line

Brand :Daseon

Product origin :China

Delivery time :30 Days

The metal briquetting production line, as an efficient and intelligent solution, is gradually being widely applied. It will detail an advanced metal briquetting production line, which combines six integrated units, working closely coordinated, interlocked, and precisely cooperated under the control of PLC, achieving automation and high efficiency in metal chip processing.

Core Units & Technical Features

1. Automatic Bin Lifter & Tipper

Function: Automates loading/unloading of scrap containers.

Technical Highlights:

Hydraulic drive ensures smooth operation (3-ton capacity).

Reinforced steel chain conveyor prevents misalignment during lifting.

Safety compliance: magnetic door locks, power-cut triggers, and inspection windows.

2. Swarf Grinding Machine

Function: Reduces long metal turnings to uniform chips.

Technical Highlights:

Adjustable motor power (18.5–75 KW) for diverse scrap types.

European-grade alloy blades (8,000-hour lifespan) minimize downtime.

Touchscreen interface with overload protection and auto-shutdown.

3. Centralized Collection Silo

Function: Buffers shredded scrap for steady press feeding.

Technical Highlights:

High-capacity storage reduces refilling frequency.

Screw feeder ensures consistent material flow to the press.

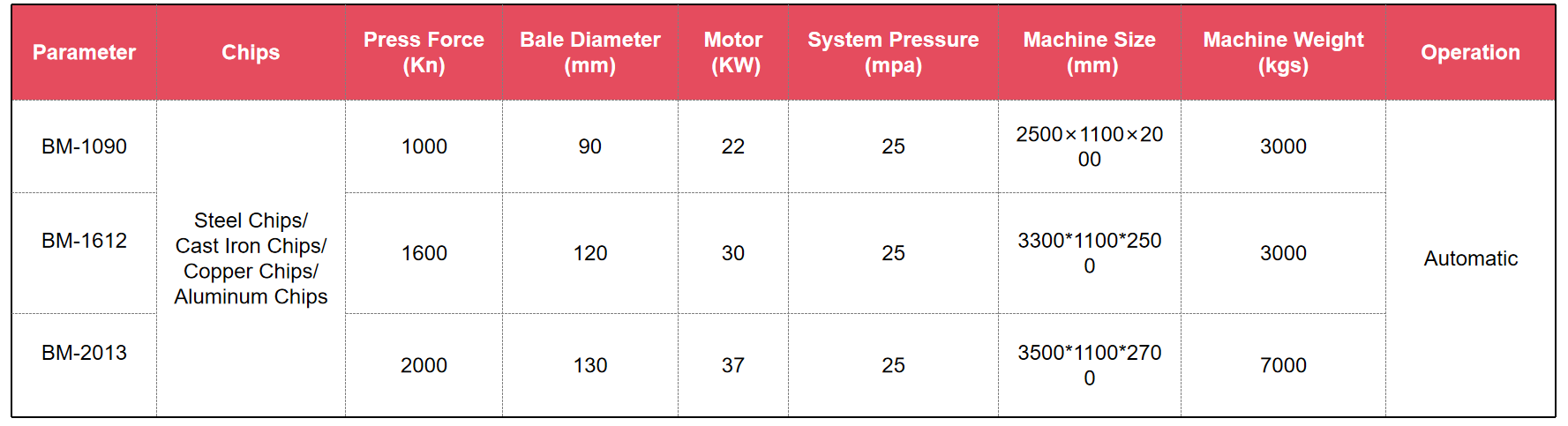

4. Hydraulic Briquetting Press

Function: Compacts chips into dense briquettes (90–130mm diameter).

Technical Highlights:

Integrated compression chamber and ram (European hardened steel, 10,000-hour durability).

Hydraulic system with intelligent cooling (25–45°C oil temperature).

5. Steel Chain Conveyor

Function: Enclosed transfer of chips to prevent spillage.

Technical Highlights:

Scraper plates achieve 98% cleanliness.

Corrosion-resistant construction for oily/coolant environments.

6. Liquid Recovery System

Function: Reclaims and filters coolant/oil from metal scraps.

Technical Highlights:

Dual-stage filtration recovers ≥95% liquid for reuse.

Automated pumping triggered by liquid level sensors.

Advantages of Metal briquetting production line

1. Create New Revenue Streams

By selling metal briquettes to foundries, enterprises can create new revenue streams. Metal briquettes are more convenient for transportation and storage compared to loose metal chips, and are more popular with foundries, which can bring additional economic benefits to enterprises.

2. Save Costs

3. Meet Sustainability Goals

In today's society, the sustainable development of enterprises has received increasing attention. The metal briquetting production line meets the sustainable development goals of enterprises by recycling and reusing resources, reducing the impact on the environment, and enhancing the social image of enterprises.

4. Increase Melting Yield

Metal briquettes can be melted directly, and ensure less slag and burn - off. The metal briquetting production line makes the melting process more efficient and increases the melting yield. In the melting process, loose metal chips are likely to produce more slag and burn - off, while briquetted metal chips have high density, melt more fully, reduce waste, and increase yield.

5. Reduce Hazardous Waste

Through the effective treatment of metal chips and resource recycling, the generation of hazardous waste is reduced. This is not only conducive to environmental protection but also complies with relevant laws and regulations, avoiding legal risks faced by enterprises due to improper handling of hazardous waste.

6. Save Space and Reduce Transportation Costs

Metal briquettes reduce volume through compression, saving storage space. At the same time, the reduction in volume also reduces transportation costs, whether it is storage within the enterprise or transportation to external places such as foundries, it is more convenient and economical.

7. Recover Valuable Coolant Lubricants and Oils

During the briquetting process, valuable coolant lubricants and oils can be recovered. These recovered liquids can be reused after treatment, further reducing the production costs of enterprises and at the same time reducing environmental pollution.

Technical Information

The metal briquetting production line offers a turnkey solution for industrial scrap management, combining precision engineering with sustainability. By transforming metal waste into reusable briquettes, it drives cost savings, environmental compliance, and operational efficiency. For tailored configurations or technical inquiries, contact our engineering experts.